Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

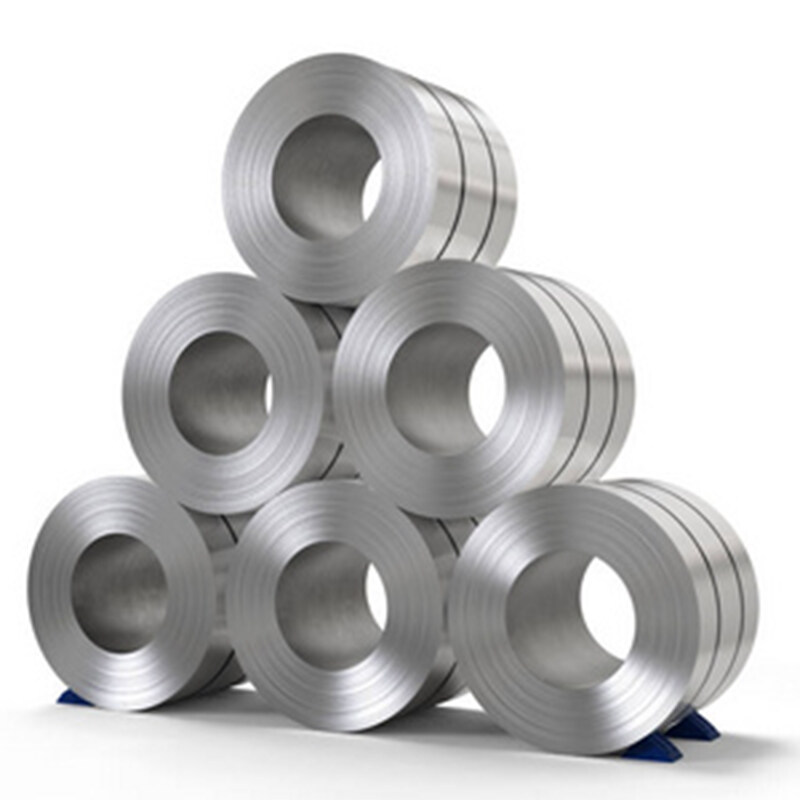

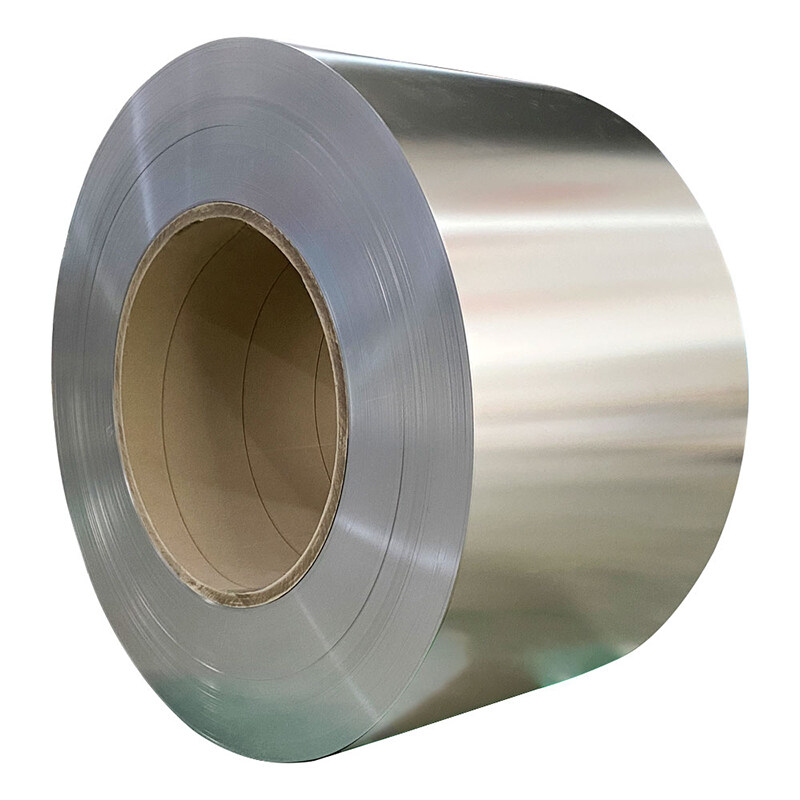

Customized cold rolled 304 316 stainless steel

This custom cold-rolled steel offers superior strength and durability, with a sleek and modern look. Our product is fully customizable, allowing you to choose the size, shape, and thickness of the steel to fit your exact needs. With its corrosion-resistant properties, it is ideal for both indoor and outdoor applications. This product is perfect for any job, big or small, and is sure to provide you with a long-lasting, quality solution.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

When cold rolled 304 316 stainless steel strips, in addition to controlling the relevant process flow, it is also necessary to pay attention to the influence of various factors that may occur during production on the process effect. Among them, there are four major factors, let us look at it together!

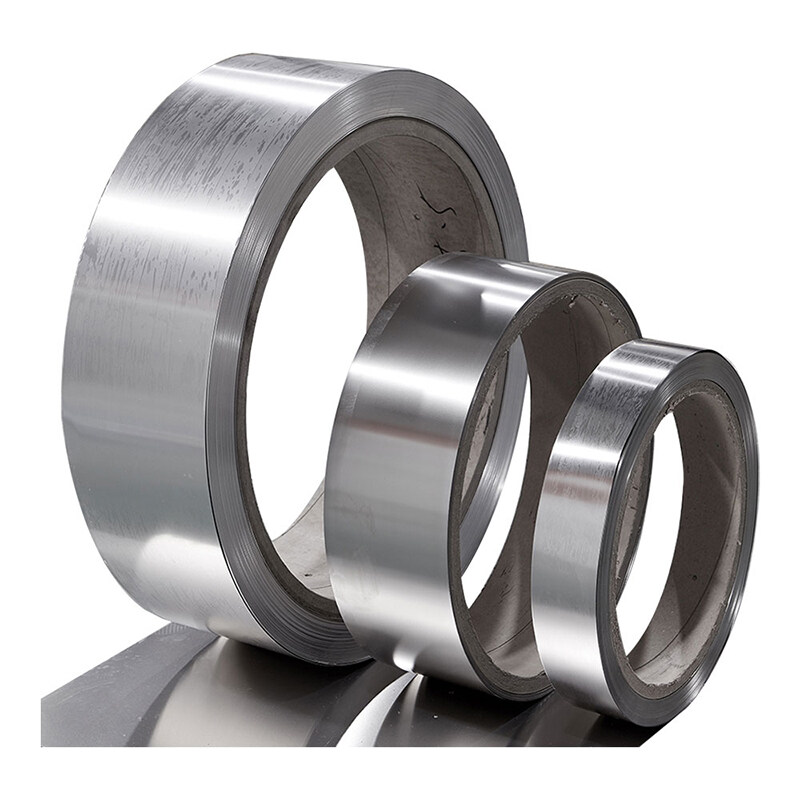

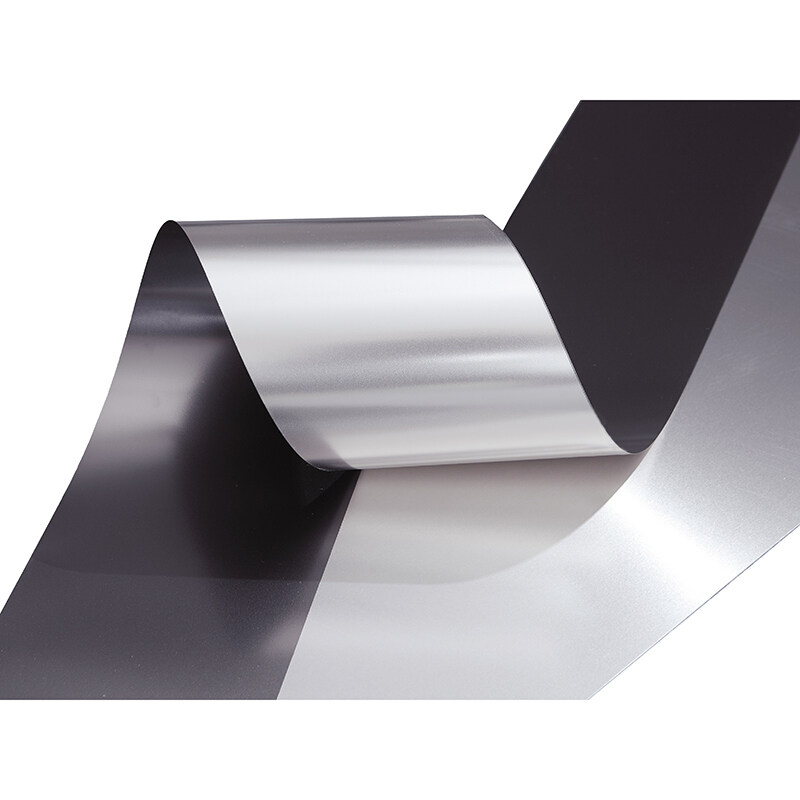

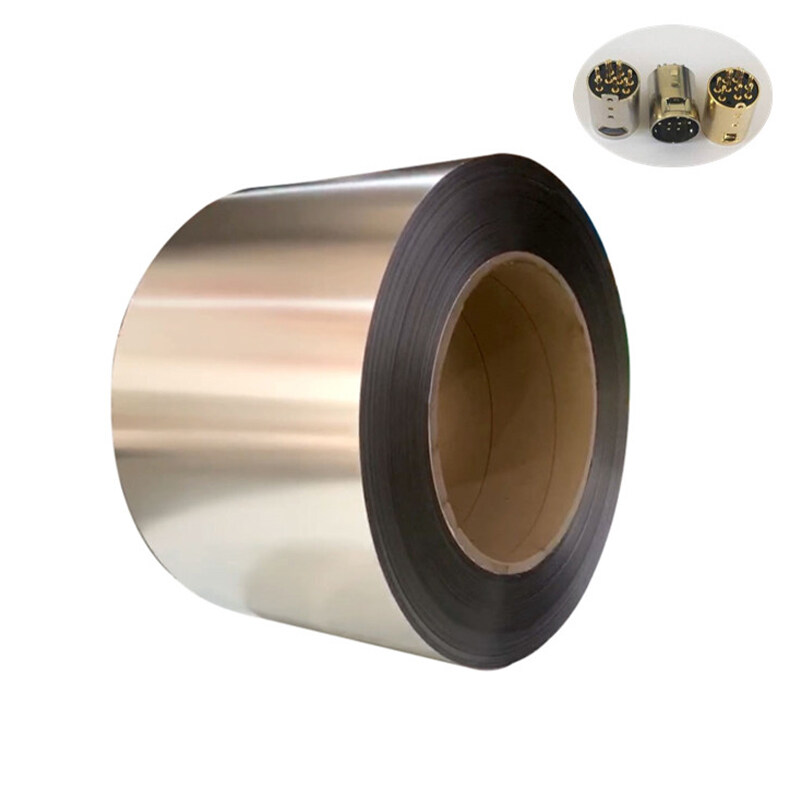

The Customized Cold Rolled 304 316 Stainless Steel offers superior strength and durability, with a sleek and modern look. The stainless steel is fully customizable, allowing you to choose the size, shape, and thickness of the steel to fit your exact needs. And you can also customize the shape, like strip, sheet, coil, or roll.

Microstructural Complexities:

The microstructural complexities of cold-rolled 316 stainless steel can lead to the formation of different textures during the rolling process. This can result in anisotropic behavior, where the material exhibits different mechanical properties in different directions. However, with proper handling and processing, the anisotropic behavior of cold-rolled 316 stainless steel can be managed effectively, allowing for the creation of high-quality products with consistent mechanical properties.

Excellent Resistance to Staining:

Thanks to its smooth surface, the material is incredibly easy to clean and maintain. Even when it gets dirty, you can simply use water to clean it, making it a convenient and hassle-free choice for a wide range of applications. Additionally, the material is non-polluting, which means that it won’t have a negative impact on the environment. This makes it an excellent choice for those who are looking for a sustainable and eco-friendly option.

Delicate Cold Rolled Technology:

Cold rolled stainless steel is a top-performing material that offers excellent precision and surface quality. It is highly efficient in processing 316 stainless steel without damaging the surface coating. This material is known for its superior organization and performance during the manufacturing process, resulting in high-quality products with precise dimensions and a smooth surface finish.

Customized Shape:

We can totally customize the shape to fit your specific needs. Whether you want it in a coil, strip, sheet, or roll, just let us know and we’ll make it happen. You can trust that our products are top-notch and precise.

Product Parameter:

|

Material |

201/304/304L/316/316L/430 Stainless Steel Sheet |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

AiSi |

|

Surface Finish |

2B |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Grade |

300 Series |

|

Length |

10-12000mm or Customized |

|

Thickness |

0.1mm-3mm or Customized |

|

Certification |

RoHS, GS, ISO9001 |

|

Width |

10-1200mm or Customized |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Electronic Products, Automotive, Medical, etc |

Four Influencing Factors in Cold Rolling Process of Stainless Steel strip

Friction coefficient

Rolling lubricants must be added during the production of stainless steel cold rolling mills, especially when rolling on multi-roll mills. There are two purposes. On the one hand, it is to reduce the friction coefficient on the contact surface between the roll and the stainless steel strip, reduce the rolling pressure and transmission force, and improve the surface state of the stainless steel strip; on the other hand, it is used to cool the roll and the stainless steel strip. Take away the deformation heat generated in the rolling process and keep the rolling mill at normal working temperature for a long time.

Production tension

The tension during cold rolling production will have a great influence on the rolling pressure, and will also affect the shape and thickness of the stainless steel. Multi-roll mills use high tension rolling, and the tension required for cold rolling of stainless steel strips will be larger. On a single-stand reversing rolling mill, the tension is formed between the rolling mill and the coiler; the coiler that forms the front tension is in the electric working state, and the coiler that forms the back tension is the working state of power generation. In the rolling process, constant tension control is usually used to keep the tension unchanged, because the diameter of the coil of the front coiler is getting larger and larger, so the coiler will slowly decelerate; The diameter is getting smaller and smaller, so increase the speed slowly to ensure that the corresponding line speed does not change significantly.

Rolling speed

The change of rolling speed during cold rolling production will affect the friction coefficient between the roll and the stainless steel strip, which in turn will affect the change of the rolling pressure and the thickness of the stainless steel strip. The rolling speed of the multi-roll mill is relatively fast, and the rolling speed of the modern twenty-high mill can be as high as 800m/min and 1000m/min. The higher rolling speed requires the hot-rolled stainless steel strip to have completely excellent metal properties, because the influence of high-speed rolling on material defects will be higher than the influence of low-speed rolling on material defects, which makes the rolling equipment and products subject to comparison. big damage. Therefore, a lower rolling speed should be used in the first pass of rolling to facilitate accurate inspection of the rolled stainless steel strip, and to record the defect positions that easily affect the high-speed rolling.

Roll

Cold rolling mills have high requirements on the hardness, strength and wear resistance of the rolls, and also have good toughness. The roll materials used in the multi-roll cold rolling mill are high-chromium steel and high-speed steel. Different parts of the rolls should also use different compositions of steel. In order to ensure that the surface quality of cold-rolled products meets the corresponding requirements, there are also very high requirements for the surface of the work roll, which must have a certain roughness and must not have any visible defects, such as craters, cracks, etc. Rolls need to be finely ground and inspected before they can be used. During the rolling process, it is also necessary to check regularly. If a problem is found, the roll needs to be replaced immediately. In actual production, the replacement of the roll is very frequent and necessary.