Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

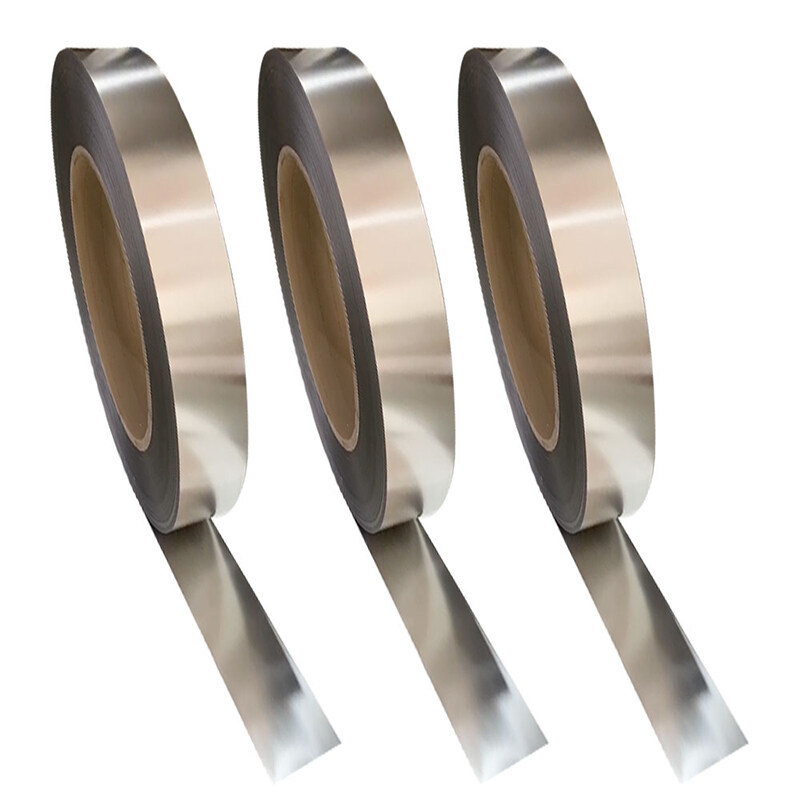

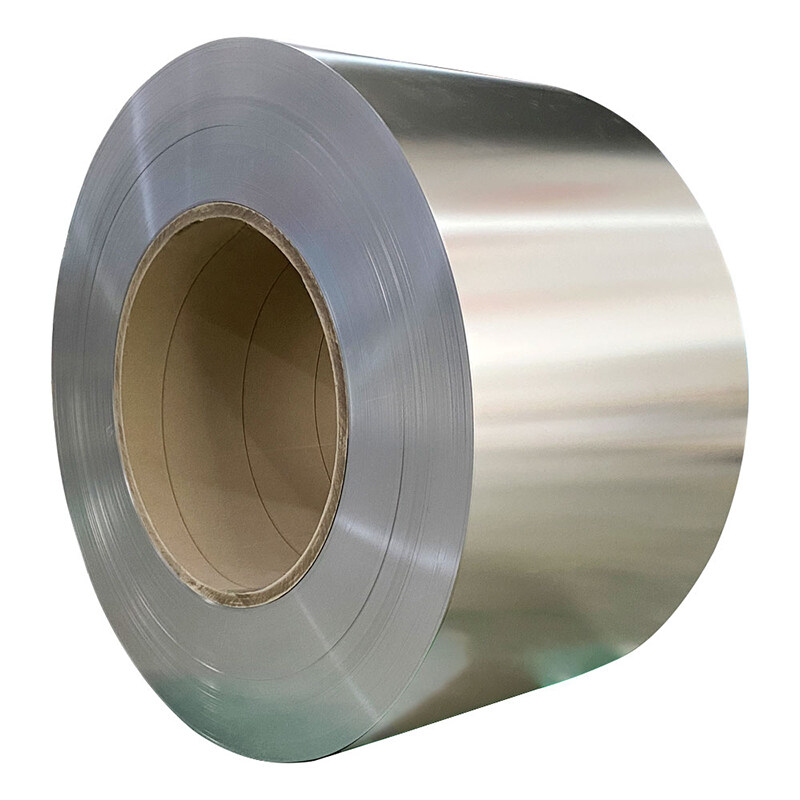

CR 304 stainless steel coil strip type 316l

The cr 304 stainless steel coil strips type 316L is in good anti-corrosion, suitable for lots of kinds of liquids. Due to the corrosion, it can be widely used in industrial and sea equipment. It’s also easy to weld, whatever the things that you want to become, by welding, you can connect any parts into anywhere that you want, this makes big function.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H,H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

CR 304 stainless steel coil strip type 316l

The 304 stainless steel coil strip is highly wear-resistant and can withstand extreme environments. For even greater durability, our 316 stainless steel coil strip is specially designed to resist acid and alkali. We offer a range of surface treatments to choose from, including BA, 2B, 8K, HL, and more, so you can select the perfect finish to meet your specific needs.

Corrosion Resistance:

The pickled surface scale found on our stainless steel coil strips is primarily composed of Cr oxides, which makes them highly resistant to corrosion. This makes our coil strips the perfect choice for use in demanding environments where corrosion resistance is essential.

Exquisite Technology:

The stainless steel coil strips are manufactured with precision using advanced strip casting technology. This innovative process results in ultrathin hot strips that offer superior dimensional accuracy and uniformity compared to standard hot-rolled strips.

Versatile for Wide Application:

Thanks to their exceptional performance, the stainless steel coil strips are suitable for use in a wide range of applications, including vehicle and mobile phone accessories. With their high temperature resistance, these coil strips can withstand even the most demanding conditions, ensuring that they remain safe and efficient even in extreme environments.

Low Price with High Quality:

The stainless steel coil strips are available for purchase in large quantities at the most competitive prices, without sacrificing quality. As a leading factory specializing in the manufacturing of stainless steel strips, we are committed to providing our customers with the highest quality products at the most affordable prices. You can trust us to deliver exceptional value for your investment, without compromising on quality or performance.

Product Parameter:

|

Material |

Stainless Steel |

|

Technique |

Hot Rolled / Cold Rolled |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Steel Grade |

301L, 301, 316L, 316, 430, 304, 304L |

|

Surface Finish |

BA |

|

Length |

Customized |

|

Thickness |

0.1-3mm |

|

Standard |

GB |

|

Width |

Customization |

|

Certificate |

API, RoHS, JIS, ISO9001 |

|

Grade |

300 Series |

|

Tolerance |

±1% |

|

Processing Service |

Welding, Punching, Cutting, Bending, Decoiling |

|

Application |

Vehicle, Mobile Phone Accessories |

Application:

- Automotive Industry: such as exhaust systems, trim, and decorative parts;

- Construction Industry: in the construction of buildings, bridges, and other structures due to their high strength and corrosion resistance;

- Food Processing Industry: due to their resistance to corrosion and ability to withstand high temperatures;

- Medical Industry: in the manufacturing of medical equipment and devices due to their biocompatibility and resistance to corrosion;

- Electronics Industry: such as computer hardware and mobile phone accessories, due to their high strength and durability.

Cold-rolled stainless steel is generally produced in coils. It is stainless steel sheet when it is flattened. Small batches of individual steel grades are produced by single sheet stainless steel sheet. Single sheet rolling is also suitable for trial production of new models and large-sized thicker steel sheets.

The production process of cold-rolled stainless steel plate is not only the cold-rolling process, but also includes heat treatment, pickling and grinding, leveling, cross-cutting to steel plate or longitudinally-cutting steel strip, and classification, cleaning and packaging of hot-rolled steel strip.

Because of the characteristics of stainless steel materials and the special requirements for product quality, the stainless steel cold rolling production process has the following characteristics.

Characteristics of cold rolling production process of stainless steel strip

First of all, due to the large rolling deformation resistance of stainless steel materials, in order to improve efficiency and ensure high rolling accuracy, a rolling mill with high rigidity is used, usually a multi-roll cold rolling mill.

Multi-roll cold rolling mills usually use a single-machine reversible rolling method, and the head and tail parts wound on the coiler are not rolled during rolling, and will be cut off as scraps. In order to improve the yield, a section of lead strip should be welded at both ends of the stainless steel strip before rolling, and the lead strip part is not rolled; in addition, if the quality of the hot-rolled stainless steel coil is too small, in order to improve the rolling efficiency and yield, Small steel coils should be welded into large steel coils in advance; in continuous annealing and pickling units, because of continuous operation, the head and tail connection parts of the steel strip should also be welded. Therefore, welding is an indispensable link in the production process of stainless steel strips. The welding difficulty of stainless steel is much higher than that of ordinary steel, so a specific welding process is also a feature of cold-rolled stainless steel strip production.

Before cold-rolling the stainless steel strip, the hot-rolled coil needs to be annealed first, and intermediate annealing is required during the cold-rolling process, and the final product needs to be finished annealing, so annealing is also a key link in production. There are many kinds of stainless steel materials, and their properties are different. The purpose, method and requirements of heat treatment are not exactly the same, and the process system is relatively unique.

Cold-rolled stainless steel sheets and strips have very strict requirements on their surface quality, and neither metallurgical and processing defects caused by the previous process nor obvious defects caused by cold-rolling are left. Therefore, various related elimination and protection measures have been adopted in the cold rolling production process. In fact, the cold rolling production process is a meticulous process, and its advantages are much higher than the production of other steel grades.

In addition, the finishing of stainless steel strips also has special requirements. For example, the flattening process should not only optimize the shape of the plate, but also use rolls with extremely low roughness to produce common bright 2B stainless steel plates. If it is ferritic stainless steel, it is also necessary to The formability of stainless steel sheets is optimized by controlling the amount of flattening. Because the stainless steel material is relatively hard; and there are stricter requirements on the straightness, it must be straightened with a strong straightening machine, and different straightening methods must be adopted according to the different thickness of the product.

What we have

Floor space: more than 20,000 square meteres

Production capacity: annual production capacity of more than 10,000 tons

16 years experience: Focus on the precision metal alloy material industry for more than 16 years.

Our services

- Customers' Request

- Free Sample

- Special Surface Processing

- Second Treatment according to customer requirements, such as: surface, width, etc.

Logistics

Transportation: sea, land

Delivery time: 15-25 working days

Packing: plastic film inside, woven bag outsourced and transported in a custom wooden box.

FAQ?

Q: What is the MOQ?

A: MOQ: 500kg.

Q: What is your delivery time?

A: 7-25 working days.

Q: What is the payment method?

A: 30% deposit is paid in advance before production, and the balance is paid before shipment

Q: Can you guarantee the quality of the product?

A: Yes, we can.

Q: Are you a factory or a trading company?

A: Industry and trade integration

Q: Where is your factory?

A: Room 101, Building B, No. 3 Education North Road, Yixin Community, Pingdi Street, Longgang District, Shenzhen, welcome to visit.

Q: Are custom services available?

A: Yes, they are available.

Q: Do you support OEM and ODM?

A: Yes.

Q: Why choose us?

A: We have a number of slitting, shearing, electroplating, painting, wire drawing surface treatment production lines, which can meet the needs of different customers, rich market resources, sufficient inventory, complete specifications, and a complete technical team.

Q: Does your packaging ensure product safety?

A: Yes, we adopt quality package.

Q: What information do I need to provide to get an accurate quote?

A: Please provide us with these information: material, hardness, surface, width, thickness.

Q: How can I get product progress without going to your company?

A: We provide one-to-one customer service.

Q: How can I deal with this if I don't receive the item?

A: We will have special personnel responsible for following up the logistics of the goods.

Q: How is your after-sales service?

A: The company will have special personnel responsible for following up the logistics of the goods.

Q: Can samples be ordered?

A: Yes, they can.

Q: How much is the sample fee, can it be refunded after bulk product?

A: Samples are free, so all no fees are refunded.

Q: Do you provide quality assurance?

A: Yes.

Q: Do you support providing samples?

A: Free sample (without shipping).

Q: What is the monthly supply capacity?

A: 1000 tons/month.