Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

0.5mm 2B BA cold rolled stainless steel 304 316 coil

Looking for high-quality austenitic cold-rolled stainless steel coils? Our 0.5mm 2B BA coils range from 304 to 316 stainless steel and are available for you to choose from. With proper maintenance, these coils can last for many years, providing excellent value for your investment. The price of these coils is dependent on the material used, with higher quality materials commanding a higher price. We offer a range of options to suit your needs, allowing you to choose the perfect type for your specific requirements.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

Not only is the price of our 0.5mm 2B BA Austenitic Cold Rolled Stainless Steel 304 316 Coil reasonable, but it also offers exceptional durability. With proper maintenance, these coils can last for many years, providing excellent value for your investment. We offer a range of options to suit your needs, and our bulk pricing options make it even more affordable for large orders.

Austenitic:

304 stainless steel coils are the most commonly used type due to their excellent resistance to oxidation and rust, which helps maintain their bright and sleek appearance. They are also easy to weld and shape into various parts, and can be cleaned with ease. With a superb combination of strength and light weight, these coils offer excellent value for their reasonable price, making them a popular choice across a wide range of industries.

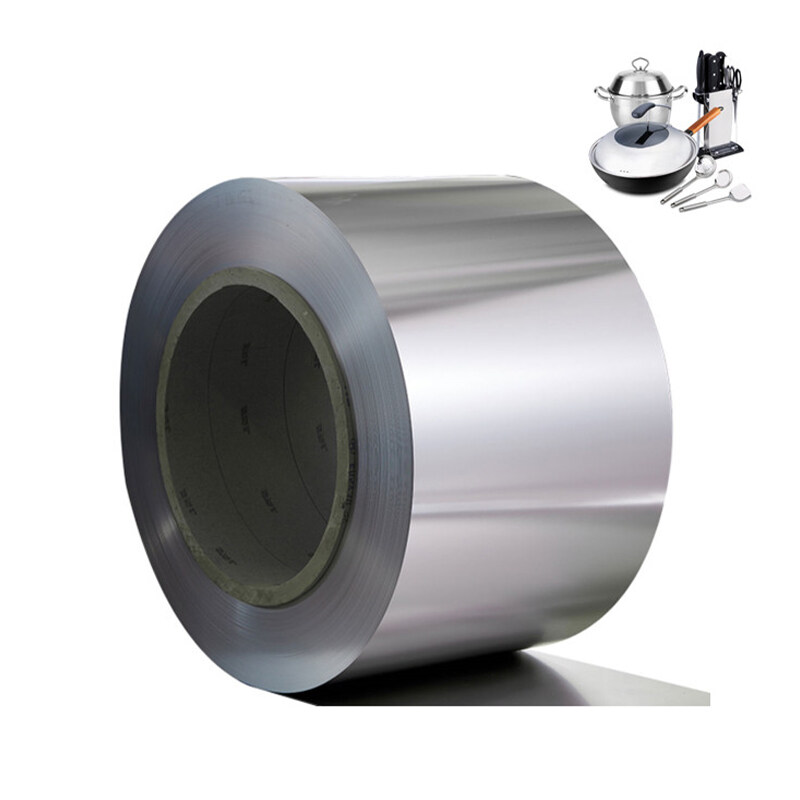

Versatile for Wide Application:

304 316 stainless steel coils are highly versatile and can be used in a wide range of industries due to their exceptional strength and durability. Some common industries that use these coils include kitchen appliances, automotive, construction, medical equipment, and chemical processing. In addition to their functional applications, these coils are also used as decorative components due to their strong corrosion and rust resistance.

Manufacturing Price with Stainless Steel Coils:

We offer competitive manufacturing prices without compromising on quality, ensuring that you receive the best value for your investment. Our pricing is transparent and fair, with no hidden fees or markups. If you are considering using stainless steel for your project, please do not hesitate to contact us.

Product Parameter:

|

Stainless Steel Coil Compositions |

|||||||||

|

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

N |

Mo |

|

SUS 201 |

≤0.15 |

≤1.00 |

5.5-7.5 |

≤0.06 |

≤0.030 |

1.5-5.5 |

16.0-18.0 |

≤0.25 |

|

|

SUS 301 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

6.0-8.0 |

16.0-18.0 |

|

|

|

SUS 304 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

8.0-10.5 |

18.0-20.0 |

|

|

|

SUS 430 |

≤0.12 |

≤0.75 |

≤1.00 |

≤0.040 |

≤0.030 |

|

16.0-18.0 |

|

|

|

SUS 316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

10.0-14.0 |

16.0-18.0 |

|

2.0-3.0 |

|

SUS 316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

12.0-15.0 |

16.0-18.0 |

|

2.0-3.0 |

|

Material |

Stainless Steel |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Hardness |

150HV-570HV |

|

Standard |

JIS, AiSi, ASTM, GB, DIN, EN SKU |

|

Surface Finish |

2B/ BA |

|

Length |

Customized |

|

Thickness |

0.03mm-2.5mm/ Customized |

|

Certification |

ISO 9001/ IATF16949 |

|

Width |

10mm-600mm or As Request |

|

Tolerance |

±1% |

|

Processing Service |

Decoiling, Punching, Cutting |

|

Application |

Mobile Phone Backlight, Connectors, Electronic Stamping, Automotive and Medical |

Correct maintenance of stainless steel coils

The use of stainless steel coils has developed with the development of stainless steel economy. Nowadays, people are more closely related to stainless steel coils in their daily life, but many people still don't know much about the performance of stainless steel coils, and even less about the maintenance of stainless steel coils. Many people think that stainless steel coils will never rust. In fact, stainless steel coils have good corrosion resistance. The reason is that a passive film is formed on the surface, which exists in the form of more stable oxide in nature. In other words, although the stainless steel coils have different degrees of oxidation according to different service conditions, they are finally oxidized. This phenomenon is usually called corrosion.

All metal surfaces exposed in corrosive environment undergo electrochemical reaction or chemical reaction, and are uniformly corroded. In the passive film on the surface of stainless steel coil, the parts with weak corrosion resistance form pitting corrosion reaction and small holes due to self-excited reaction. Coupled with the proximity of chloride ions, a strong corrosive solution is formed to accelerate the speed of corrosion reaction. There are also intergranular corrosion cracks inside the stainless steel coil, all of which destroy the passive film on the surface of the stainless steel coil.

Therefore, the surface of stainless steel coil must be cleaned and maintained regularly to maintain its gorgeous surface and prolong its service life. When cleaning the surface of stainless steel coils, attention must be paid to avoid surface scratches, and the use of bleach and abrasive detergent, steel balls, grinding tools, etc. in order to remove the detergent, clean water should be used to wash the surface at the end of washing. If there is dust on the surface of stainless steel coil and dirt is easy to remove, it can be washed with soap, weak detergent or warm water.

The trademark and film on the surface of stainless steel coil shall be washed with warm water and weak detergent, and the adhesive composition shall be scrubbed with alcohol or organic solvent (ether, benzene). If the oil, grease and lubricating oil on the surface of stainless steel coil are polluted, wipe it with a soft cloth, and then clean it with neutral detergent or ammonia solution or special detergent. The surface of stainless steel coil has bleach and various acids attached. Wash it with water immediately, and then soak it with ammonia solution or neutral carbonic acid soda solution, and wash it with neutral detergent or warm water. There are rainbow lines on the surface of stainless steel coil, which is caused by excessive use of detergent or oil, When washing, use warm water neutral detergent to wash it off.

Remind

The rust caused by the dirt on the surface of the stainless steel coil can be washed with 10% nitric acid or grinding detergent, or with special washing drugs. As long as we use the correct maintenance methods and clean regularly, the service life of the stainless steel coil can be extended and its original cleanness, brightness and ornateness can be maintained!