Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

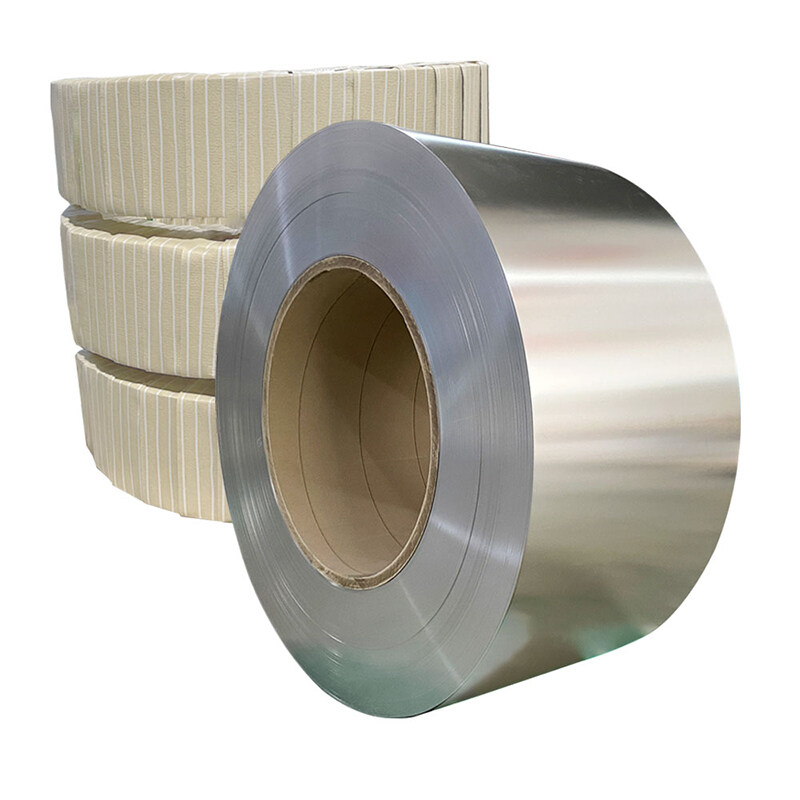

Custom 304 304L Stainless steel coil strip belt

304L stainless steel coil strip belt is the perfect choice for custom projects that require high quality and low price. Made of 304 and 304L grade stainless steel, this belt is designed to provide superior strength and durability. It is resistant to corrosion, rust, and other damage. The coil strip belt is available in a variety of sizes and can easily be cut to fit specific needs to meet any project requirements.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

Our Custom High Quality Low Price 304 304L Stainless Steel Coil, Strip, and Belt are designed to provide superior strength and durability. They’re resistant to corrosion, rust, and other types of damage. Available in a variety of sizes, they can easily be cut to fit specific project requirements. As a well-known stainless steel coil, sheet, and roll factory in China, we’re committed to providing you with the best service and products possible.

High Quality Stainless Steel Coil and Strip:

The stainless steel coil and strip has good ductility. It’s also highly resistant to corrosion, which is a major advantage. When selecting a stainless steel coil strip belt, it’s important to check for any rust spots on the surface, as this can indicate a lack of corrosion resistance. The collective iron in the stainless steel coil strip belt gives it a high level of hardness, which can make it difficult to cut, bend, or crimp accurately during processing, especially under high temperatures.

Easy to Process and Use:

The stainless steel coil strip belt boasts a smooth surface, high plasticity, toughness, and mechanical strength. It’s also highly resistant to corrosion from acid, alkaline gas, solution, and other types of media. While it’s an alloy steel that’s not prone to rust, it’s important to note that it’s not completely rust-free. Please note the special liquids in advance! This makes it easier to process and use.

Versatile in Multiple Fields:

Stainless steel coil strip belts are widely used in construction, industrial production, and other fields. They offer many excellent characteristics, including high temperature resistance, deformation resistance, and corrosion resistance, making them ideal for use in construction and other industries.

Product Parameter:

|

Material |

301/ 304/ 304L/ 316/ 316L Stainless Steel Sheet |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

AiSi, JIS |

|

Certification |

API, RoHS, JIS, GS, ISO9001 |

|

Surface Finish |

BA |

|

Grade |

200/ 300/ 400 Series |

|

Length |

Customized |

|

Thickness |

0.1mm-3mm or Customized |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Width |

Customized |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting, Moulding |

|

Application |

Shield, Mobile Phone Accessories, 3C Product |

Stainless steel coil is a kind of material that needs processing. It is widely used in the processing industry, and the products produced are widely used. Do you know about the characteristics of stainless steel coil strip belt in use? How to distinguish the quality of stainless steel coil strip belts?

Characteristics of stainless steel coil strip belts

As a processing material, the machinability of stainless steel coil strip belts is the key to whether the finished products can be processed. However, the processing of low-quality stainless steel coil strip belts is inconvenient, and the quality of the finished products is much worse.

High quality stainless steel tape: good ductility. Moreover, the stainless steel coil strip belt has good corrosion resistance. A major feature of stainless steel coil strip belts is corrosion resistance and not easy to rust. When selecting stainless steel coil strip belts, we should pay attention to whether there are rust spots on the surface of stainless steel coil strip belts, so as to judge whether the stainless steel coil strip belts are corrosion resistant. stainless steel coil strip belt is the existence of collective iron, which leads to the high hardness of this kind of stainless steel coil strip belt. Especially under high temperature conditions, the high hardness and high strength of stainless steel coil strip belt make it difficult to achieve accurate cutting, bending, crimping and other processing effects in the processing process.

stainless steel coil strip belt has smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion of acid, alkaline gas, solution and other media. stainless steel coil strip belt is a kind of alloy steel that is not easy to rust, but it is not absolutely rust free.

Most stainless steel coil strip belts are used in construction, industrial production and other fields. Stainless steel tape has many excellent characteristics, such as high temperature resistance, deformation resistance and corrosion resistance, so it can be used in construction and other industries.

Introduction of corrosion resistance of stainless steel coil strip belts

Stainless steel reels have good corrosion resistance in the production process of pulp and paper, as well as the corrosion of ocean and corrosive industrial atmosphere.

Different series of stainless steel coil strip belts have little difference in chemical corrosion resistance, but they differ in some specific media.

The originally developed stainless steel coil strip belt is 304, which is sensitive to pitting corrosion under certain circumstances. Adding an additional 2-3% molybdenum can reduce this sensitivity, which gives birth to 316. In addition, these additional molybdenum can also reduce the corrosion of some thermal organic acids.

316 stainless steel tape has almost become the standard material in the food and beverage industry. Due to the worldwide shortage of molybdenum and the more nickel content in 316 stainless steel coil strip belts, the price of 316 stainless steel coil strip belts is more expensive than 304 stainless steel coil strip belts. Pitting corrosion is a phenomenon mainly caused by deposition corrosion on the surface of stainless steel, which is due to the lack of oxygen and the inability to form a chromium oxide protective layer. Especially in small valves, the possibility of deposition on the valve plate is very small, so pitting corrosion rarely occurs.

In various types of water media (distilled water, drinking water, river water, boiler water, sea water, etc.), the corrosion resistance of 304 stainless steel coil strip belt is almost the same as that of 316 stainless steel coil strip belt, unless the content of chloride ion in the media is very high, at this time, 316 stainless steel coil strip belt is more suitable. In practical application, steel resistant to weak corrosion medium is often called stainless steel, while steel resistant to chemical medium is called acid resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical medium corrosion, while the latter is generally rust free.