Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

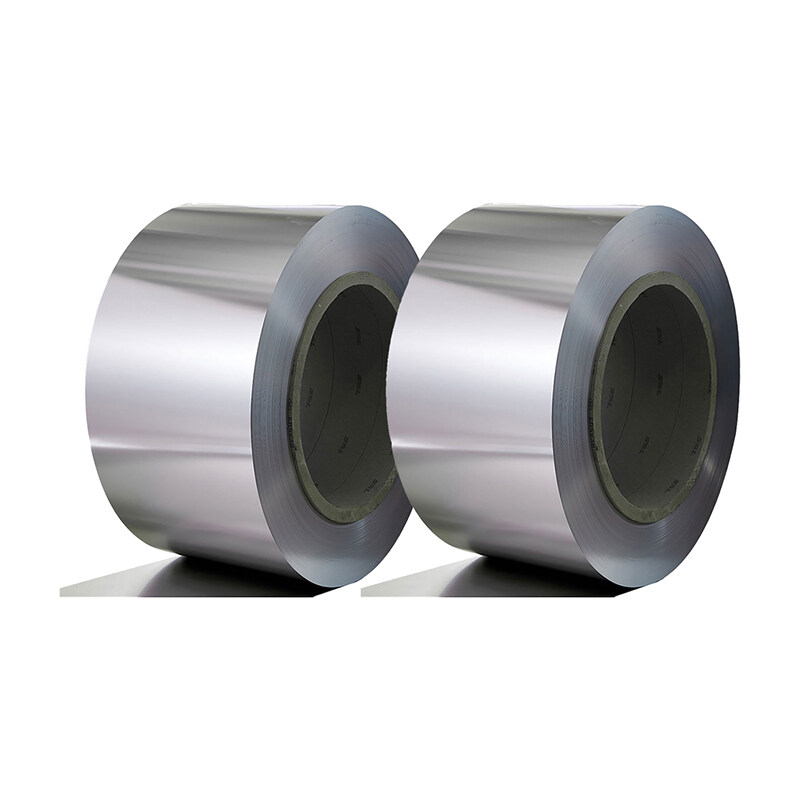

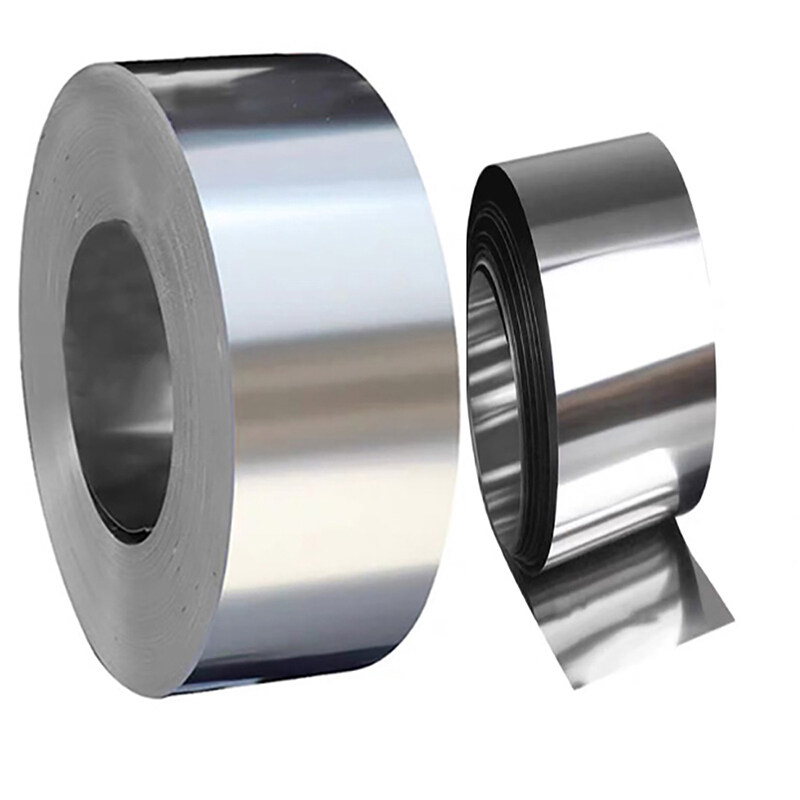

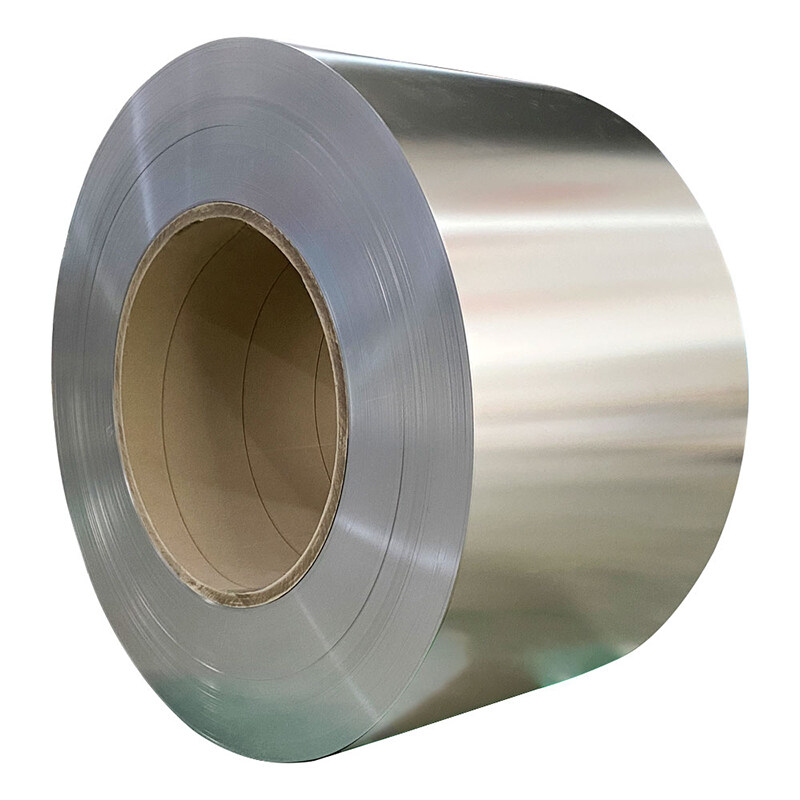

Hot rolled cold rolled 0.03mm-3mm ss 201 stainless steel coil

Our hot rolled and cold rolled SS 201 stainless steel coils are available in a range of thicknesses from 0.03mm to 3mm, allowing you to choose the perfect thickness for your needs. Our coils are known for their tough strength, ensuring that they won’t easily break or become damaged. As direct sellers from stainless steel coil manufacturers, we guarantee that our coils are of the highest quality and will meet your expectations. Trust us to provide you with the support you need to succeed.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

This is our hot rolled cold rolled 0.03mm-3mm ss 201 stainless steel coil 304 304 202 430 316 316.

The Hot Rolled Cold Rolled 0.03mm-3mm SS 201 Stainless Steel Coil, with a thickness range of 0.03mm to 3mm, is a versatile material that can be welded using various techniques to create a wide range of items. Its cost-effectiveness and improved strength, compared to other stainless steel grades, make it a popular choice in various applications.

High Strength:

SS 201 stainless steel coil is a top choice for applications where strength is a crucial factor. Compared to other austenitic stainless steel grades, it has higher yield strength and tensile strength, making it a reliable option for demanding applications. This feature makes it a popular choice in various industries, including construction, automotive, and manufacturing.

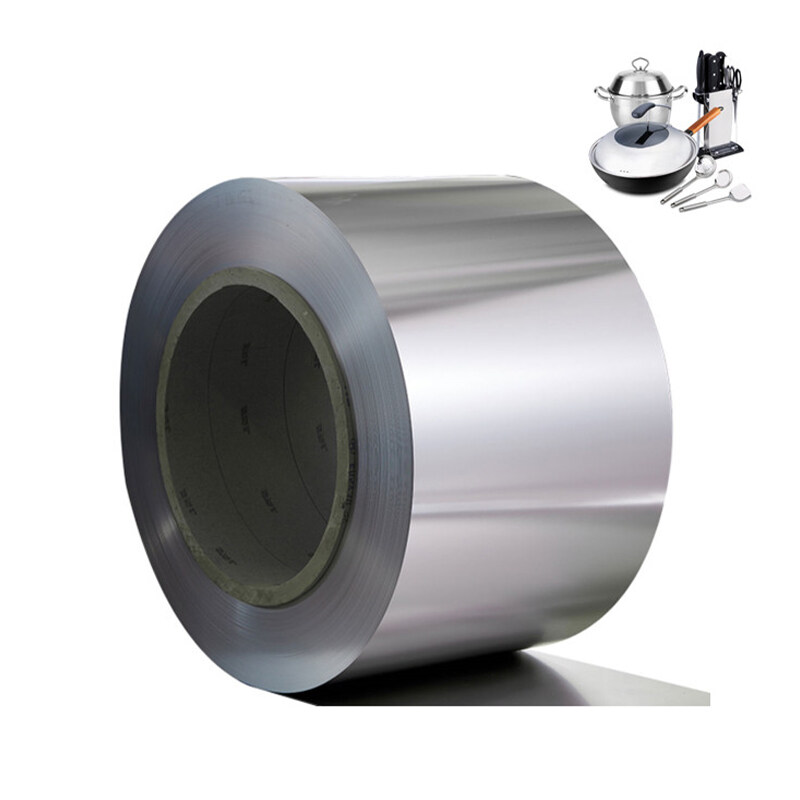

Versatile Application:

SS 201 stainless steel is a versatile material that finds its use in various industries, including chemical, food, medicine, papermaking, petroleum, and atomic energy. It’s also a popular choice for construction, kitchen utensils, tableware, vehicles, and household appliances.

Exquisite Polished without Pinholes:

The SS 201 stainless steel coil has a super smooth surface without any pinholes, making it perfect for those who want high-quality and smooth finishes. You might not even need to do any extra treatment because it’s ready to use right out of the box. That’s why it’s a popular choice in industries like electronics, automotive, and construction. Plus, it’s super durable and resistant to corrosion, so you know it’ll last.

Cheap and Cost-effective Price:

The SS 201 stainless steel is a practical choice for many because of its affordable price and excellent corrosion resistance, which ensures long-lasting performance. It’s a cost-effective option for those starting a new business and looking to save on costs. With its durability and resistance to corrosion, it’s a reliable choice for various applications. Whether you’re building a new company or looking to upgrade your materials, SS 201 stainless steel is a smart choice that won’t break the bank.

Product Parameter:

|

Material |

201/304/304L/316/316L/430 Stainless Steel Sheet |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Standard |

GB |

|

Surface Finish |

2B |

|

Length |

Customized |

|

Hardness |

1/4H, 1/2H, 3/4H, EH, SH |

|

Thickness |

0.03mm-3mm/ Customized |

|

Certification |

API, RoHS, ISO9001 |

|

Width |

As Request |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

3C Electronic Products |

In modern stainless steel coil production, annealing and pickling combined units are generally used for pre and post cold rolling treatment. Annealing and pickling are important processes in the production of stainless steel hot-rolled and cold-rolled coils. Their principles and processes play a very important guiding role in actual production. The selection of annealing equipment, pickling method and pickling conditions directly affect the final quality of stainless steel products.

Annealing process of stainless steel coil

Tropical annealing

The hardness of stainless steel coil increases after hot rolling, accompanied by carbide precipitation. The purpose of annealing stainless steel coils of different steel grades is different.

Solution treatment of austenitic stainless steel

Austenitic stainless steel will precipitate carbides after hot rolling, and the grains will deform with processing. The purpose of austenitic stainless steel annealing is to heat the steel to the annealing temperature (1010 ~ 1150 ℃), so that the precipitated carbides are fully dissolved in austenite at high temperature, and then quickly cooled (water-cooled quenching), so that the carbon dissolved in austenite remains at room temperature. At the same time, the grain size is adjusted during annealing to achieve the purpose of softening.

Due to the need for rapid cooling to prevent the re precipitation of carbides, the austenitic stainless steel coil after hot rolling can only be used in a continuous annealing furnace.

Annealing of ferritic and martensitic stainless steels

A certain amount of martensite will be produced during the cooling process of most ferritic stainless steel coils after hot rolling. The main purpose of annealing is to decompose martensite into ferrite and grain like or spherical carbides, so as to achieve the purpose of softening; In addition, annealing can also change the elongated grains into equiaxed grains during rolling.

Martensitic stainless steel coils are austenite at high temperature. Martensitic transformation occurs during cooling after hot rolling, and high hardness martensitic structure is obtained at room temperature. The purpose of annealing is to decompose this martensite into spherical carbides uniformly distributed on the ferrite matrix, so as to soften the steel.

The precipitation, aggregation and spheroidization of carbides during annealing of martensitic stainless steel coils and ferritic stainless steel coils take a long time, so the hot-rolled coils of this kind of stainless steel are usually annealed in bell type furnace. Of course, for single-phase ferritic steel without martensite after hot rolling, it is more reasonable to choose continuous furnace.

Cold strip annealing

Cold strip annealing of stainless steel coils can be divided into intermediate annealing and finished annealing.

The purpose of intermediate annealing is to eliminate the work hardening in the cold rolling process, so that the cold rolled stainless steel strip can be softened by recrystallization annealing for the next rolling process. The final annealing process is generally the same as the intermediate annealing, and individual products are subject to special treatment according to needs.

Continuous annealing furnace is used for cold strip annealing. Generally, horizontal cold strip annealing and pickling machine is used. For Ba plate, it needs to enter the bright annealing production line for treatment.