Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

SECC DX51 Zinc coated strips Cold rolled/Hot Dipped Galvanized Steel Coil Sheet Plate strips

The SECC zinc coated strips cold rolled or hot dipped galvanized steel coil sheet is anti-rust, and it can always keep the smooth and bright appearance. It has long service life, can be kept with many years. Besides, it’s difficult to be corrosive, and zinc has stable chemistry, can well resist of any liquids, like acid or alkali, to keep the original appearance in long time.

-

0.2mm-3mm

-

Customization

About SECC products, our SECC DX51 Zinc coated strips Cold rolled/Hot Dipped Galvanized Steel Coil/Sheet/Plate/strips are popular now, welcome to visit our website. Learn more, and welcome to contact us directly.

The SECC zinc-coated strips are treated with cold rolling or hot dipping dependant on your needs, resulting in improved accuracy of size and strength. This makes it an ideal material for use in the automotive industry, where safety is of utmost importance. With a service life of more than 10 years, parts made from this material offer stable and long-lasting performance, ensuring that they will continue to perform reliably over time.

Smooth Surface:

The zinc coated strips feature a surface treatment that results in a smooth and bright appearance, capable of withstanding serious wear and tear. The flawless surface exudes a sense of sophistication and luxury, making it the perfect choice for high-end applications.

Difficult to Deform:

The stainless steel strips are specially treated to resist high-strength shock and maintain their original shape, making them incredibly tenacious and versatile for creating a variety of parts.

Rustproof:

The stainless steel is treated with galvanized technology, providing excellent resistance to oxidation and rust, especially when exposed to oil and other chemical substances.

No Pollution:

The stainless steel strips are crafted from environmentally friendly materials, ensuring that they never produce any harmful or polluting substances for the environment or our bodies. We take great care to ensure that our products are not only high-quality and durable, but also safe and sustainable.

Dust Resistance:

Thanks to its smooth surface, our stainless steel is incredibly easy to clean and maintain. Simply wipe away any dirt or grime, and it will look as good as new. Additionally, our stainless steel is highly resistant to dust and oil, ensuring that it stays stylish and clean for longer periods of time. Unlike other materials, our stainless steel does not absorb dust, making it a practical and hygienic choice for a wide range of applications.

Product Parameter:

|

Material |

Stainless Steel |

|

Technique |

Cold Rolled Finish/ Hot Dipped |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Steel Grade |

Galvanized |

|

Surface Treatment |

Galvanized |

|

Length |

1000-12000mm |

|

Thickness |

Customized |

|

Standard |

AiSi, ASTM, GB, JIS |

|

Width |

Customized |

|

Process Surface |

Cutting, Bending, Decoiling, Welding, Punching |

|

Tolerance |

±3% |

Application:

- Electronics: such as computer cases, mobile phone cases, and other electronic devices;

- Automotive: particularly for the production of car bodies, doors, and other components;

- Construction: for roofing, cladding, and other applications where durability and corrosion resistance are essential;

- Appliances: such as refrigerators, washing machines, and dishwashers;

- Furniture: particularly for modern and contemporary designs.

What is SECC?

SECC is a stamping material, which is coated with a zinc layer on the surface of cold-rolled sheet. Rust and corrosion prevention. The price is quite high. Generally, the thickness of the plate is 0.4 ~ 3.2 mm.

SECC application

Household appliances: refrigerator, washing machine, clothes dryer, air conditioner, video recorder, CD player, color TV, recorder, microwave oven, stereo.

Automobile: body panel, radio, fan, air filter, filter, fuel tank.

Office machines: printers, copiers, monitors, telex machines, electronic computer cases.

Building: partition wall, door, keel.

Production machinery: agricultural machinery, industrial robots

Cleaning industry: operating room wall decoration

Others: distributor, oil storage tank, motor cover, steel furniture floor.

What is galvanized steel?

Galvanized steel refers to the steel surface coated with a layer of metallic paint zinc in order to prevent the steel surface from being corroded and prolong its service life. This kind of steel coated with zinc is called galvanized steel.

Galvanized steel is chemically treated to prevent corrosion. This steel is coated with zinc because rust is difficult to corrode this protective metal material.

The main way to make steel corrosion resistant is to add other metals, such as zinc. After the steel is immersed in zinc, the chemical reaction will make zinc permanently plated on the steel. Therefore, zinc not only covers the steel paint, but also becomes a part of it.

What is galvanizing?

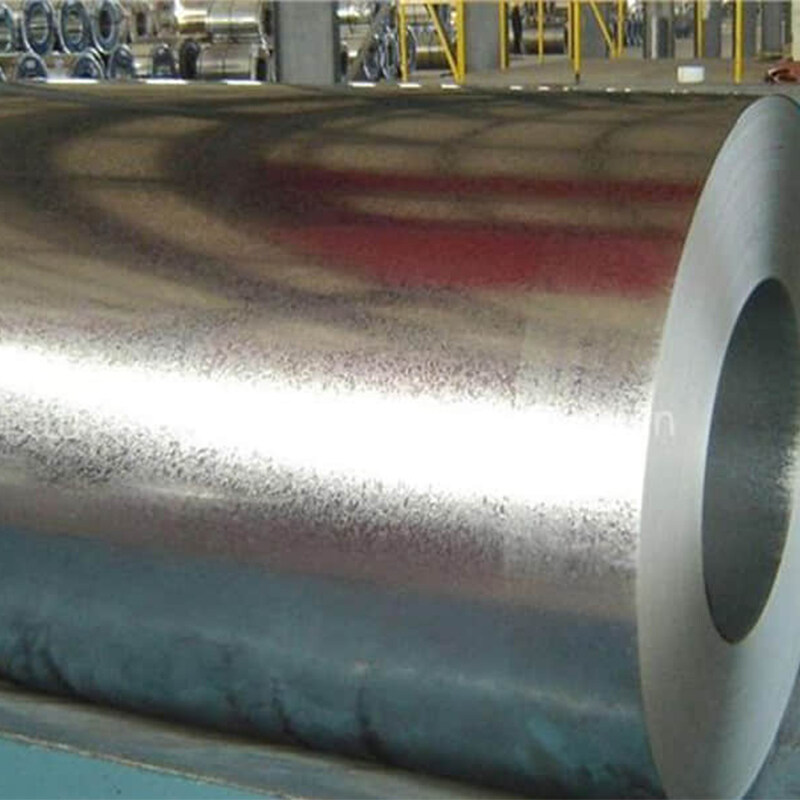

Hot Dip Galvanizing

Hot dip galvanizing is a unique process. When the clean steel is immersed in the molten zinc, a series of zinc ferroalloy layers are formed through the metallurgical reaction between iron and zinc, providing a solid coating, which is an integral part of the steel.

Coating

The process is completed when the reaction between iron and zinc has actually stopped and the product is taken out of the galvanizing bath together with its free zinc outer coating. In fact, there is no boundary between steel and zinc, but gradually transition through a series of alloy layers that provide metallurgical bonding.

Galvanizing process

Hot dip galvanizing is a process in which steel coils are immersed in a bath of molten zinc to produce a corrosion-resistant multilayer coating of zinc iron alloy and zinc metal. When steel is immersed in zinc, metallurgical reaction occurs between iron in steel and molten zinc. The reaction is a diffusion process, so the coating is formed perpendicular to all surfaces, forming a uniform thickness on the whole part.

How does galvanizing protect the base steel coil?

- Zinc coating can prevent corrosive substances such as acid (such as acid rain) from contacting the metal below.

- Galvanizing can prevent rust. When the coating is scratched, zinc will still be easier to "sacrifice the anode" than the base metal to prevent rust.

- Zinc protects metals by faster corrosion than base metals. Sometimes, a special component called "chromate" is added to galvanized metal, which makes it corrode faster.

How galvanizing protects steel coil?

Galvanizing provides barrier protection between all internal and external steel surfaces and their environment. Galvanizing is a term that is often incorrectly used to describe zinc coatings. The expected life of a zinc coating depends largely on its thickness. Thicker coatings last longer. Hot dip galvanizing provides maximum protection for fabricated iron or steel products through a thicker, continuous, tough, metallurgically bonded coating.

Why galvanizing in steel coil?

Durable

It is very simple to galvanize the metal to make it anticorrosive. Without a protective zinc coating, the metal will be exposed to the natural environment and may oxidize and corrode faster.

One of the main benefits of using hot dip galvanizing is its durability. Data show that galvanizing can provide 34 to 170 years of protection for steel. One of the main air pollutants affecting the performance of hot-dip galvanizing is sulfur dioxide.

Sustainable

Galvanizing has achieved long-term durability with relatively low environmental burden in terms of energy and other global related impacts.

Galvanized steel is around us and plays a vital role in our daily life. It is used in construction, transportation, agriculture, power transmission and anywhere, good corrosion prevention and long life are essential.

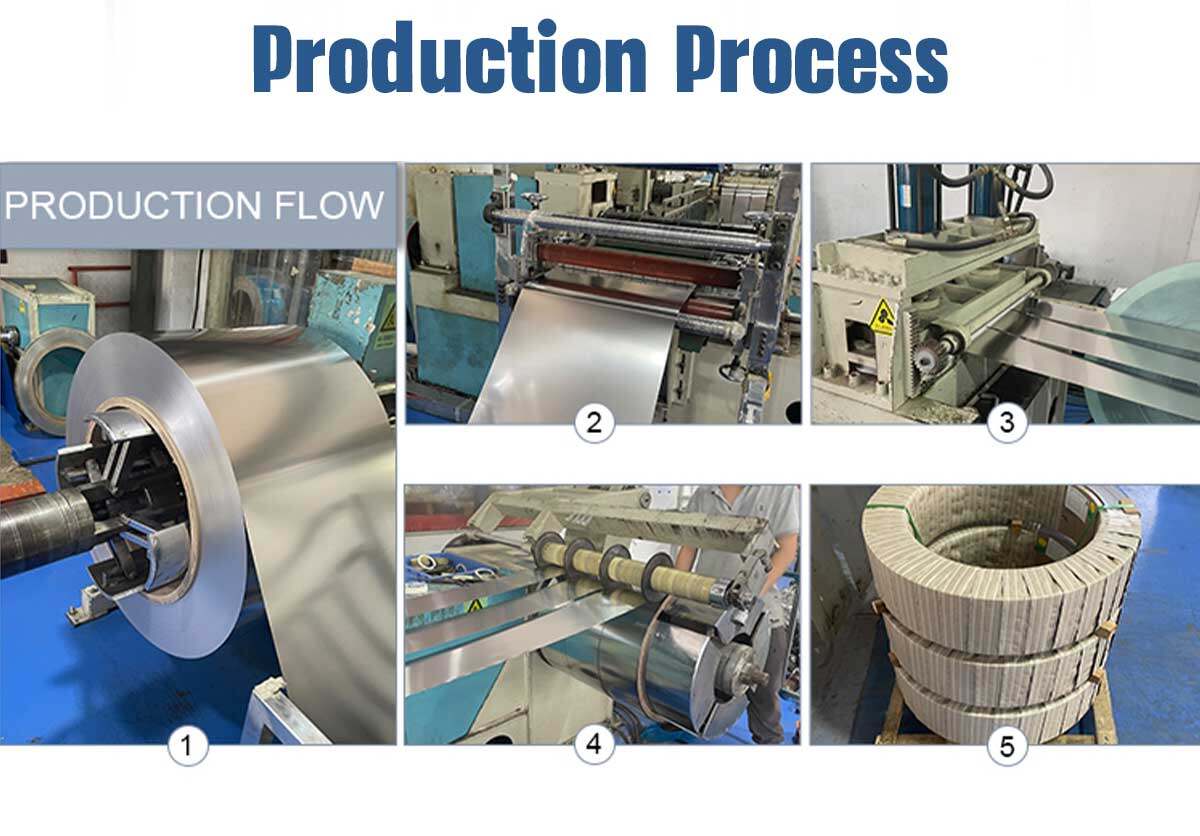

What we have

Floor space: more than 20,000 square meteres

Production capacity: annual production capacity of more than 10,000 tons

16 years experience: Focus on the precision metal alloy material industry for more than 16 years.

Our services

- Customers' Request

- Free Sample

- Special Surface Processing

- Second Treatment according to customer requirements, such as: surface, width, etc.

Logistics

Transportation: sea, land

Delivery time: 15-25 working days

Packing: plastic film inside, woven bag outsourced and transported in a custom wooden box.

FAQ

Q: What is the MOQ?

A: MOQ: 500kg.

Q: What is your delivery time?

A: 7-25 working days.

Q: What is the payment method?

A: 30% deposit is paid in advance before production, and the balance is paid before shipment

Q: Can you guarantee the quality of the product?

A: Yes, we can.

Q: Are you a factory or a trading company?

A: Industry and trade integration

Q: Where is your factory?

A: Room 101, Building B, No. 3 Education North Road, Yixin Community, Pingdi Street, Longgang District, Shenzhen, welcome to visit.

Q: Are custom services available?

A: Yes, they are available.

Q: Do you support OEM and ODM?

A: Yes.

Q: Why choose us?

A: We have a number of slitting, shearing, electroplating, painting, wire drawing surface treatment production lines, which can meet the needs of different customers, rich market resources, sufficient inventory, complete specifications, and a complete technical team.

Q: Does your packaging ensure product safety?

A: Yes, we adopt quality package.

Q: What information do I need to provide to get an accurate quote?

A: Please provide us with these information: material, hardness, surface, width, thickness.

Q: How can I get product progress without going to your company?

A: We provide one-to-one customer service.

Q: How can I deal with this if I don't receive the item?

A: We will have special personnel responsible for following up the logistics of the goods.

Q: How is your after-sales service?

A: The company will have special personnel responsible for following up the logistics of the goods.

Q: Can samples be ordered?

A: Yes, they can.

Q: How much is the sample fee, can it be refunded after bulk product?

A: Samples are free, so all no fees are refunded.

Q: Do you provide quality assurance?

A: Yes.

Q: Do you support providing samples?

A: Free sample (without shipping).

Q: What is the monthly supply capacity?

A: 1000 tons/month.