Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

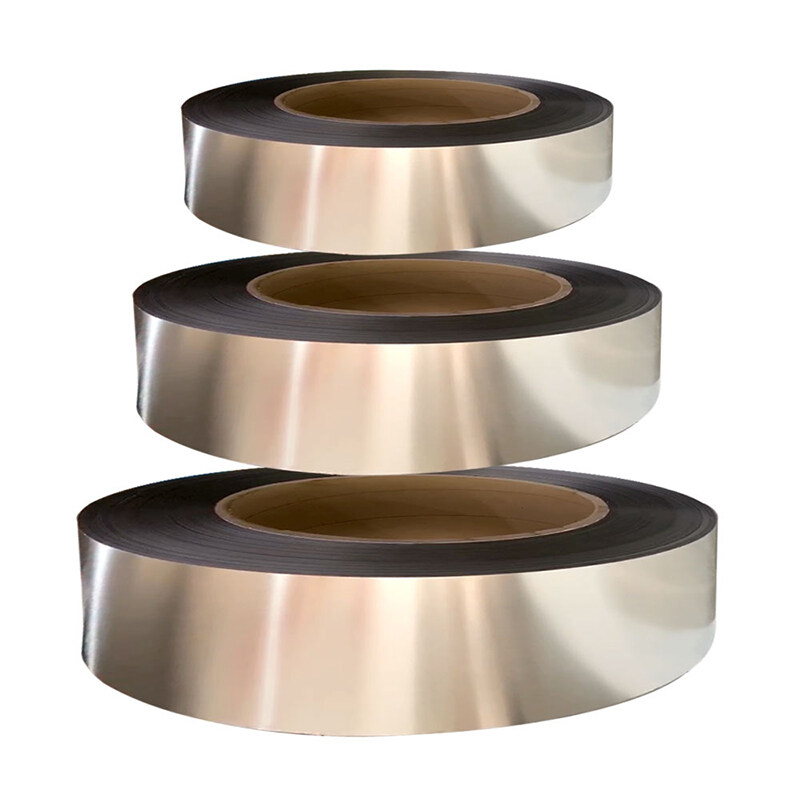

1.0mm thick coil 316 430 cold rolled stainless steel coil

This cold-rolled stainless steel coil price is the perfect choice for any project requiring a durable, corrosion-resistant material. It features superior strength and ductility, making it ideal for industrial applications. The 1.0mm thickness ensures a long-lasting product that is sure to stand up to the toughest conditions. With its superior resistance to high temperatures, this coil is perfect for use in both hot and cold environments.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

If you’re looking for a high-quality stainless steel coil, the 1.0mm Thick Coil 316 430 Cold Rolled Stainless Steel Coil Price is definitely worth considering. Our delicate cutting machine ensures that the coil is cut precisely to meet your specific needs. With its superior resistance to high temperatures, this coil is perfect for use in both hot and cold environments.

Certain Degree of Work Hardness:

The cold-rolled 316 430 stainless steel coil is an excellent choice for those looking for a durable and affordable option. It has a certain degree of work hardening, which gives it good toughness and makes it resistant to wear and tear. Additionally, it’s available at a reasonable price, making it a cost-effective solution for a wide range of applications.

High Dimensional Accuracy:

The cold-rolled 316 430 stainless steel coil is made using a process of cold deformation, which results in a product with high dimensional accuracy and excellent surface quality. This makes it ideal for use in applications where precision and aesthetics are important, such as in the manufacturing of high-end appliances, automotive parts, and architectural features.

Oxidization Resistance:

The cold-rolled 316 430 stainless steel coil has a surface that is free of oxide skin, which is a sign of its excellent quality. This makes it ideal for easy clean and refined polished finish.

Widely Used in Advanced Production Process:

The cold-rolled 316 430 stainless steel coil is a versatile material that is widely used in various industries due to its unique production process. It’s commonly used to manufacture a wide range of products, including cold stamping parts, cold-rolled cold extruded profiles, cold coil springs, cold-drawn wires, cold heading bolts, and more.

Product Parameter:

|

Material |

201/304/304L/316/316L/430 Stainless Steel Sheet |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

AiSi |

|

Surface Finish |

2B |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Grade |

300 Series |

|

Length |

10-12000mm or Customized |

|

Thickness |

0.1mm-3mm or Customized |

|

Certification |

RoHS, GS, ISO9001 |

|

Width |

Customized |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Electronic Products, Automotive, Medical, etc |

We offer a range of customized services for stainless steel coils, sheets, strips, and tubes in grades 201, 304, 304L, 316, 316L, and 430. If you’re interested in any of these products, please don’t hesitate to get in touch with us! We’re happy to work with you to create a custom solution that meets your specific needs.

Does anyone else not know the difference between hot rolling and cold rolling of stainless steel?

So far, there are still many friends who can't distinguish cold rolling and hot rolling of stainless steel. Generally speaking, the surface of cold-rolled stainless steel plate is bright, smooth and beautiful; The surface of hot-rolled stainless steel plate belongs to industrial surface, rough surface and feels a little hand. Now let's talk about the difference between the two.

Hot rolling

Compared with cold rolling, cold rolling is rolling below the recrystallization temperature, while hot rolling is rolling above the recrystallization temperature.

Its characteristics:

1.Poor toughness and surface flatness, low price;

2.The temperature of hot rolling is close to that of forging;

3.The hot plate is processed by hot rolling, and the surface has oxide skin, and the thickness of the plate has a difference;

4.Because of its production technology, it is more in civil areas, such as tableware, general household appliances, etc;

5.The mechanical properties of hot-rolled stainless steel plate are far inferior to cold working and forging, but it has better toughness and ductility.

Cold rolling

It is processed and rolled on the basis of hot-rolled stainless steel coils. Generally speaking, it is a processing process of hot rolling → pickling → cold rolling. Although the temperature of stainless steel plate will rise due to rolling in the processing process, it is still called cold rolling. Cold rolling, which is formed by continuous cold deformation after hot rolling, has poor mechanical properties and high hardness. Only after annealing can its mechanical properties be restored. Those without annealing are called rolled hard coils. Rolled coil is generally used to make products without bending and stretching.

Its characteristics:

1.Cold rolled stainless steel sheet has a certain degree of work hardening, low toughness and high price;

2.Cold rolled surface is free of oxide skin, with good quality;

3.The product made of cold deformation has high dimensional accuracy and good surface quality;

4.Cold rolling is widely used in all walks of life because of its production process, such as all kinds of cold stamping parts, cold rolled cold extruded profiles, cold coil springs, cold drawn wires, cold heading bolts, etc.

The main differences between hot rolling and cold rolling are:

1.Cold rolled formed steel allows local buckling of the section, so that the post buckling bearing capacity of the member can be fully utilized; The hot-rolled section steel does not allow local buckling.

2.The causes of residual stress in hot-rolled and cold-rolled sections are different, so the distribution on the section is also very different. The residual stress distribution on the section of cold-formed thin-walled steel is curved, while the residual stress distribution on the section of hot-rolled steel or welded steel is thin-film.

3.The free torsional stiffness of hot-rolled section steel is higher than that of cold-rolled section steel, so the torsional resistance of hot-rolled section steel is better than that of cold-rolled section steel.