Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

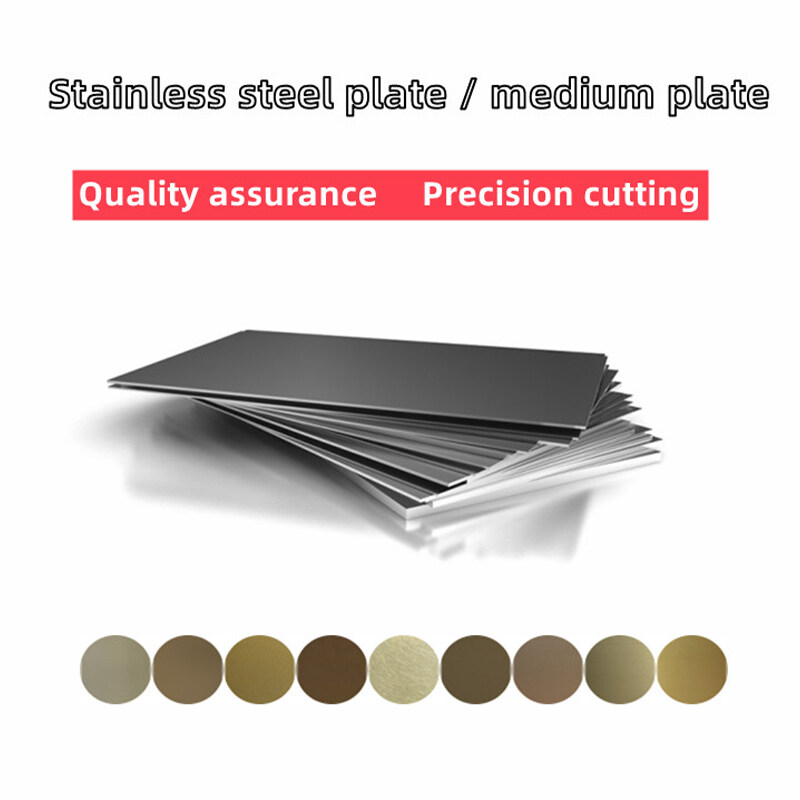

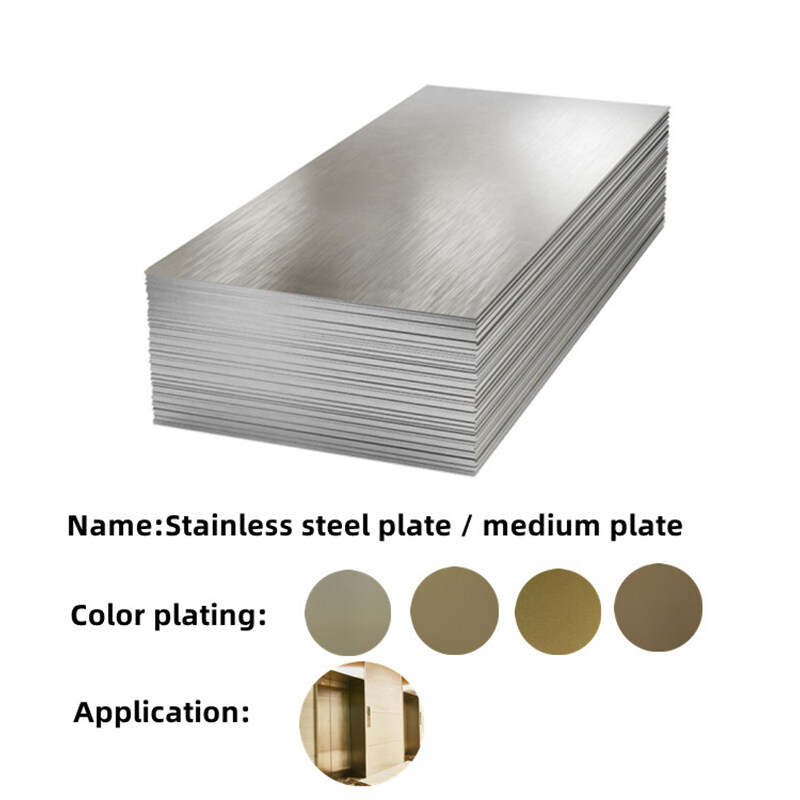

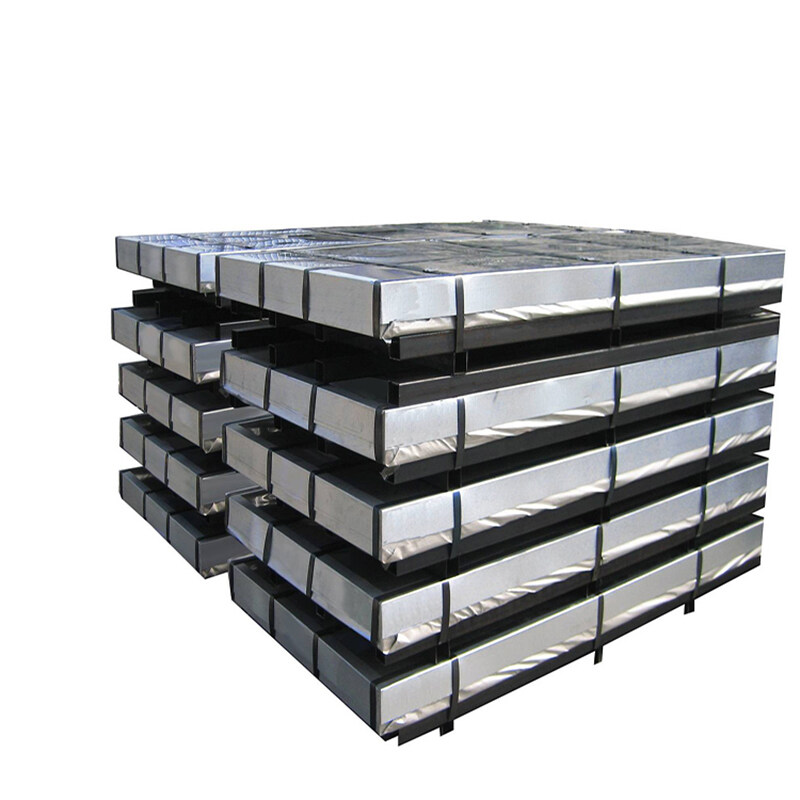

201 stainless sheet plate

201 stainless steel sheet plate is a high-quality, durable product made from corrosion-resistant stainless steel. It is perfect for a variety of applications, including food processing, chemical processing, and construction. It is easy to clean and maintain, and its corrosion-resistant properties make it ideal for long-term use. It is also heat-resistant and can withstand high temperatures, making it suitable for a variety of industrial applications.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

This 201 stainless sheet plate is a high-quality product made from durable 201 stainless steel. It is corrosion-resistant, heat-resistant, and easy to maintain. The plate is perfect for any application requiring a strong, reliable material. Its smooth surface makes it ideal for welding and fabrication, while its strength and durability make it a great choice for industrial and commercial applications.

Corrosion Resistance:

201 stainless steel sheet plate has good corrosion resistance, making it suitable for use in various applications where corrosion resistance is required. It is resistant to many types of corrosion, including atmospheric, chemical, and pitting corrosion. This makes it a practical choice for applications in harsh environments, such as marine and chemical processing industries.

High-temperature oxidation resistance:

201 stainless steel sheet plate has good high-temperature oxidation resistance, making it suitable for use in high-temperature environments. It can withstand temperatures up to 1200°F (649°C) without significant scaling or deformation. This makes it a practical choice for applications in high-temperature environments, such as furnace components and exhaust systems.

Easy to Clean:

201 stainless steel sheet plate is easy to clean and maintain, making it a practical choice for applications where hygiene is important. It is resistant to stains and can be easily wiped clean with a damp cloth.

Good Thermal Conductivity:

201 stainless steel sheet plate has good thermal conductivity, making it suitable for use in applications where heat transfer is important. It can transfer heat quickly and efficiently, making it ideal for use in heat exchangers and other similar applications.

High Strength:

201 stainless steel sheet plate has high tensile and yield strength, making it suitable for use in applications where strength is important. It is stronger than many other types of stainless steel, including 304 stainless steel, and can withstand heavy loads and high stress.

Product Parameter:

|

Technique |

Cold Rolled/Hot Rolled Galvanized |

|

Surface |

2B |

|

Steel Grade |

301L, 301, 316, 430, 304, 304L |

|

Surface Finish |

2B |

|

Length |

Customized |

|

Thickness |

0.0-3.0m |

|

Standard |

SUS |

|

Width |

1m-2m |

|

Temper |

BA/2B/NO.1/NO.3/NO.4/8K/HL/EMBOSSED |

|

Grade |

200 Series |

|

Tolerance |

±1% |

|

Processing Service |

Welding, Punching, Cutting, Bending, Decoiling |

|

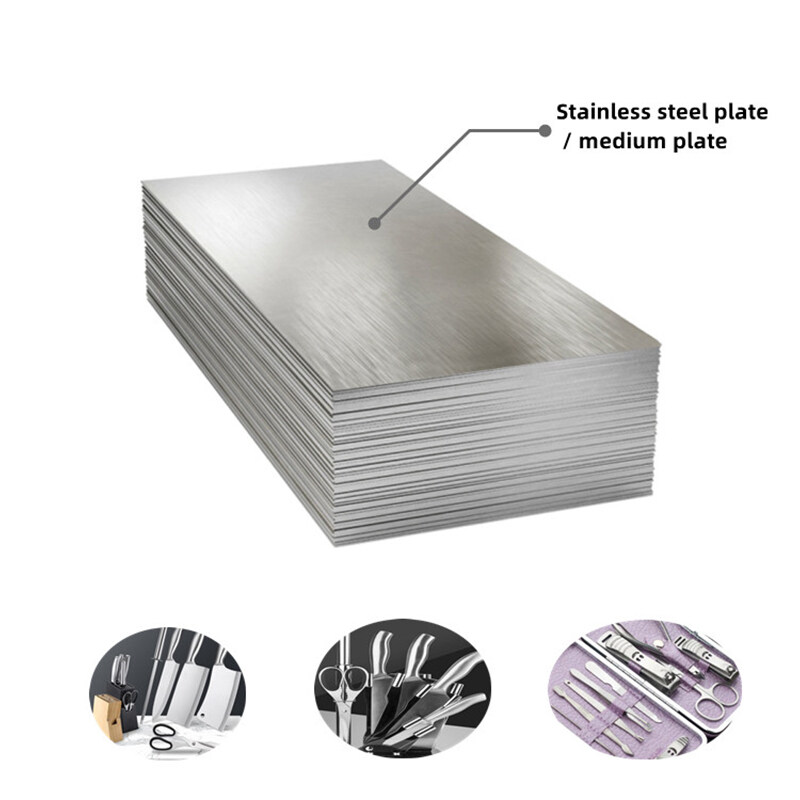

Application |

Construction Industry |

Application:

1.Decorative pipes

2.Industrial pipes

3.Boiler shells, heat exchangers, and heating furnace parts

4.Boiler pressure vessels

5.Expansion joints

6.Furnace pipes and spiral welded pipes for dryers

Definition of 201 stainless steel plate

Fluctuations in nickel prices for 200 series Cr-Mn stainless steels have prompted many producers to seek another austenitic stainless steel alternative with the same performance as AISI304. In the early 1930s, the first chromium-manganese (Cr-Mn) austenitic stainless steels were produced, in which manganese replaced part of the nickel. Since then, more research has been done on specific composition ratios, using nitrogen (N) and copper (Cu) to control the elements carbon (C) and sulfur (S) that strongly affect material properties. The reason for the application of 200 series stainless steel The success is due to the possibility of replacing 304 stainless steel in some specific applications without danger.

In contrast, 200-series stainless steels are being marketed elsewhere with little control of sulfur, carbon content, risking damage to end users and the image of stainless steel.

Characteristics of 201 stainless steel plate

Corrosion resistance

In terms of resistance to general medium corrosion, the performance of 201 stainless steel is similar to that of non-steady state nickel-chromium alloy 304 stainless steel.

High temperature oxidation resistance

201 stainless steel plate has good high temperature oxidation resistance, but it should be noted that the oxidation rate of 201 stainless steel plate in high temperature environment will be affected by inherent factors such as the exposure environment and the shape of its own products. Do the corresponding experiments to ensure that it meets the needs of use.

Thermal conductivity

As we all know, the total heat transfer coefficient of metal is not only affected by the thermal conductivity of the metal, but also depends on other factors. For example, in most cases, it is mainly reflected in the heat dissipation coefficient of the film, the surface condition of the scale and the metal. 201 stainless steel can keep the surface clean for a long time, so its heat transfer is better than many other metals with higher thermal conductivity.

Application of 201 stainless steel plate

201 stainless steel has the characteristics of acid resistance, alkali resistance, high density, no bubbles and no pinholes in polishing. Mainly used to make decorative pipes, industrial pipes, and some shallow-stretched products. Such as: petroleum waste gas combustion pipes; engine exhaust pipes; boiler shells, heat exchangers, heating furnace parts; silencing parts for diesel engines; boiler pressure vessels; chemical transport vehicles; expansion joints; furnace pipes and spiral welded pipes for dryers and many more.

201 stainless steel plate performance

lTensile Strength: 100,000 to 180,000 psi

lYield Strength: 50,000 to 150,000 psi

lElongation: 55 to 60%

lElastic Modulus: 29,000,000 psi

lDensity: 280lbs/cubic inch (density 7.93g/cm3)

Common problems about 201 stainless steel

The reason why the application of 200 series stainless steel is successful is that it is possible to replace 304 stainless steel in some specific applications. Nitrogen) replaces some or all of the nickel to produce lower nickel content austenitic stainless steels. The disadvantage of this series of materials is that the 18% chromium content and the low nickel content are not balanced and ferrite is formed. For this reason, the chromium content in the 200 series stainless steel is reduced to 15% to 16%. In some cases It has dropped to 13% to 14%, and its corrosion resistance is not comparable to 304 and other similar steels.

200 series steel will fail at these conditions approximately 10-100 times faster than 304 stainless steel. Also, the residual sulfur and carbon content of these steels is often not controlled during production, and the material cannot be traced back to its source, even when the material is recycled. If Cr-Mn steels are not specified, they can be a dangerous mix of scrap, resulting in castings with unexpectedly high levels of manganese.