Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

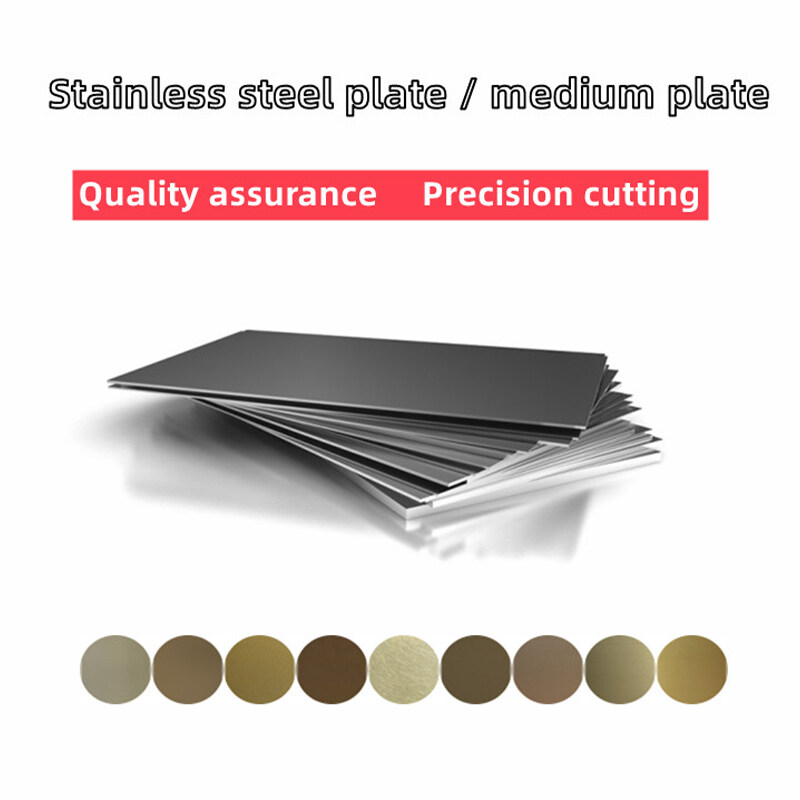

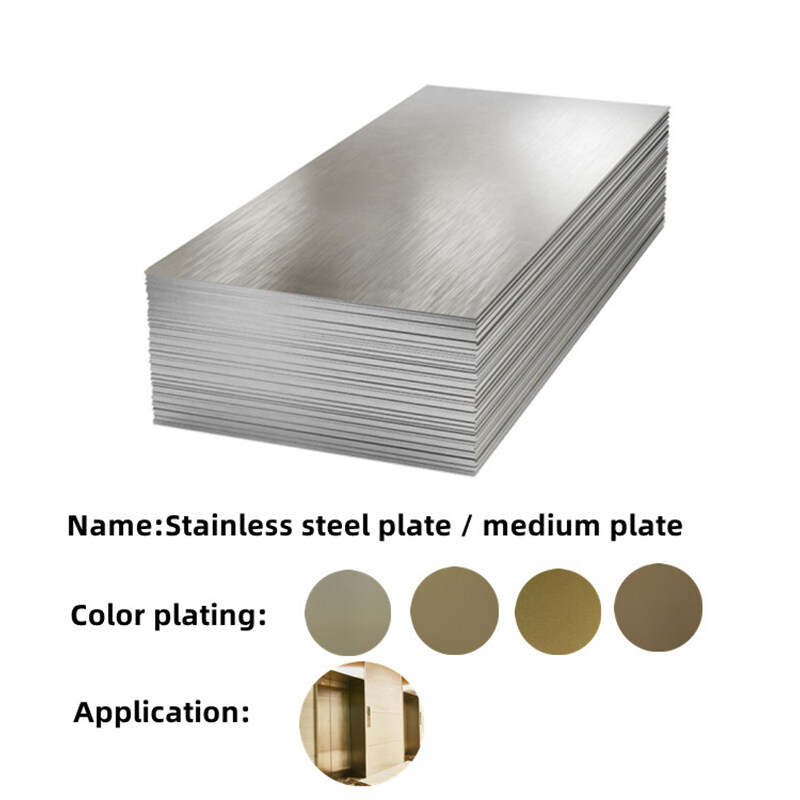

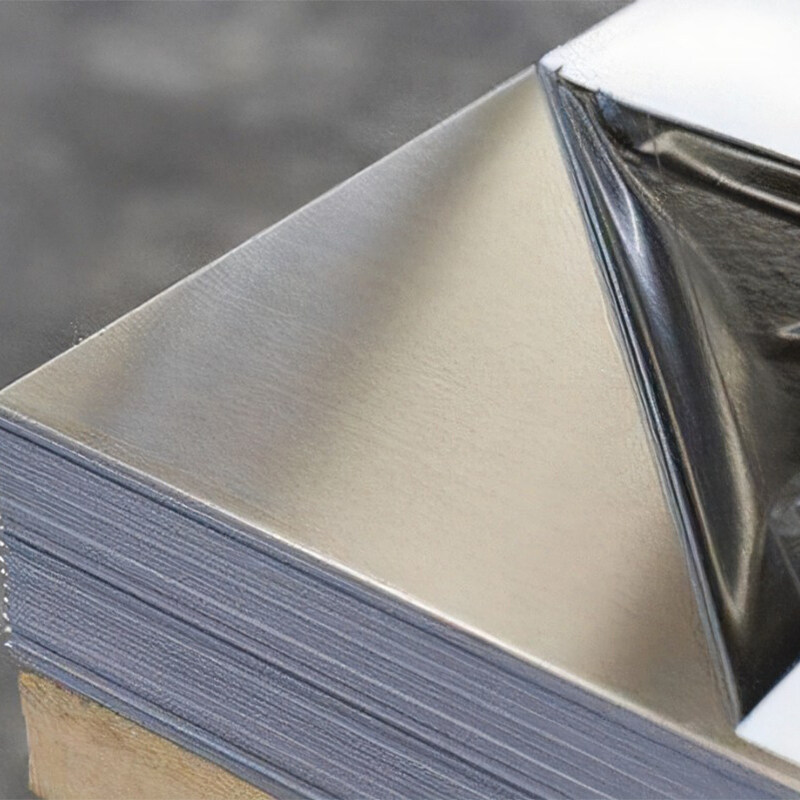

316L Cold Rolled 2B BA HL 8K Finish Stainless Steel Plate

This stainless steel plate is the perfect choice for any project. Crafted from durable 316L cold-rolled stainless steel, it is suitable for covering both large and small surface areas. Resistant to corrosion and rust, it is ideal for both indoor and outdoor use.Perfect for a variety of applications, this plate is sure to provide superior performance and long-lasting use.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

The 316L Cold Rolled 2B BA HL 8K Finish Stainless Steel Plate is the ultimate choice for any project, big or small. It’s perfect for covering surfaces of all sizes and is resistant to both corrosion and rust, making it great for indoor and outdoor use. Plus, it’s super easy to shape into any form you need, and it performs like a champ.

Good Heat Resistance:

Even in a high temperature environment, the stainless steel plate calendering material should also maintain excellent heat resistance. The strength of austenitic stainless steel sheet rolling can be significantly improved through solid solution strengthening. Carbon also improves the stress corrosion resistance of austenitic stainless steels rolled in high chloride concentrations.

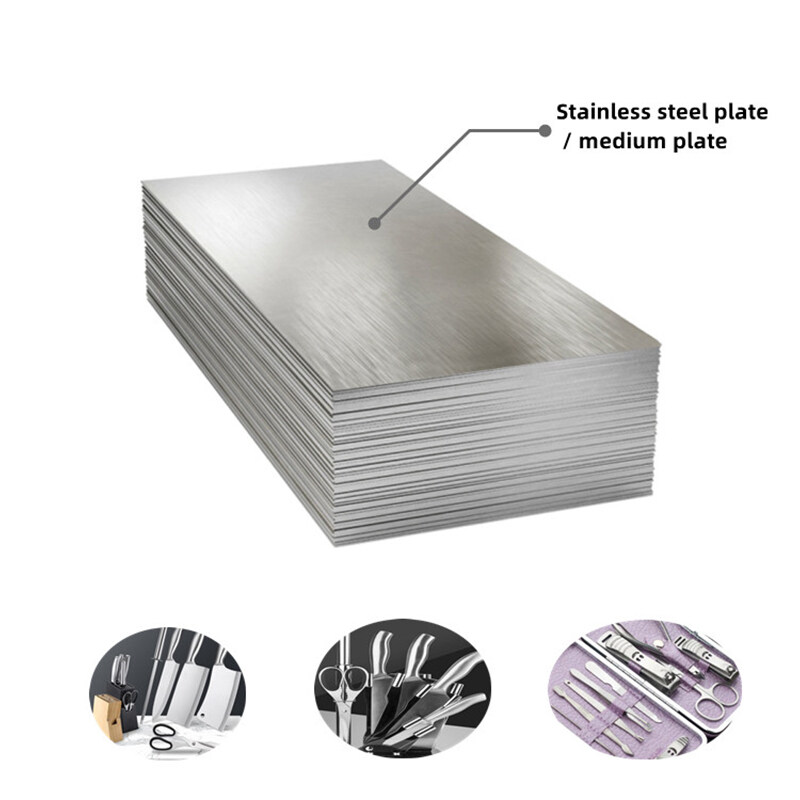

Precision Cutting:

We use advanced machines and technology to cut the 316L stainless steel plate with precision, ensuring that it meets your specific needs. You can rest assured that the sheet won’t be cut in different lengths, and we’ll get it right every time.

Food Grade:

The 316 stainless steel plate is perfect for food processing, especially for items that are prone to chemical reactions. It’s an excellent container for storing liquids or gases, thanks to its stable chemical performance. You can trust it to keep your items safe and secure.

Strong Strength in Harsh Environment:

Thanks to the addition of Mo, the 316 stainless steel plate boasts exceptional corrosion resistance, atmospheric corrosion resistance, and high-temperature strength. It’s perfect for use in harsh conditions, especially in seawater. You can rely on it to withstand even the toughest environments.

Versatile Used For:

With a maximum tolerance of 1200 to 1300℃, the 316 stainless steel plate is perfect for use in high-temperature equipment. It’s commonly used in pulp and paper equipment heat exchangers, dyeing equipment, film processing equipment, pipes, and exterior materials for buildings in coastal areas. Its versatility makes it a popular choice for a wide range of applications.

Product Parameter:

|

Material |

Stainless Steel |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

JIS |

|

Surface Finish |

2B |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Grade |

300 Series |

|

Length |

2000/2438/2500/3000/3048mm, 1000mm-12000mm |

|

Thickness |

1mm, 0.9mm, 0.8mm, 0.7mm, 0.6mm, 0.5mm, 0.4mm, 0.3mm |

|

Width |

10-1200mm or Customized |

|

Tolerance |

±5% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Decoration and Fabrication |

What is the performance of stainless steel plate calendering material? Before talking about this, let's first understand how the stainless steel plate rolling material is produced. The rolling of stainless steel plate actually refers to the processing of stainless steel with pressure and tensile ductility. The chemical composition of stainless steel can be changed by smelting, but the chemical composition of the stainless steel cannot be changed by the rolling process. The rolling process is essentially forging and pressing. Forging and finally changing the physical state of the stainless steel plate. Therefore, we can know that in the stainless steel industry, rolling processing generally refers to a series of processing processes of hot-rolled stainless steel sheets of a certain specification and thickness to make cold-rolled stainless steel sheets of a certain specification, so people will roll the finished stainless steel sheets. It is called calendering material. So what is the quality of the rolled material of the stainless steel plate?

What is the performance of stainless steel plate calendering material?

Corrosion resistance of stainless steel plate rolling stock

Most of the stainless steel plate rolling material products require good corrosion resistance, such as first and second class tableware, kitchen utensils, water heaters, water dispensers, etc. The NACL aqueous solution is placed in the product, and then the solution is poured out after a period of time. After washing and drying, the weight loss is weighed to determine the degree of corrosion of the product. When the number of chromium atoms in the stainless steel plate is higher than 12.5%, the electrode potential of the stainless steel can be abruptly changed from the original negative potential to a positive electrode potential, which can prevent the stainless steel plate from being electrochemically corroded.

Welding properties of stainless steel plate rolling stock

Different product uses have different requirements for welding performance. Most products require good welding performance of raw materials, such as second-class tableware, water heaters, steel pipes, thermos cups, water dispensers, etc.

Heat resistance of stainless steel plate rolling stock

Even in a high temperature environment, the stainless steel plate calendering material should also maintain excellent heat resistance. This is affected by the carbon element. The ability of carbon to form austenite is about 30 times that of nickel. Carbon is an interstitial element. The strength of austenitic stainless steel sheet rolling can be significantly improved through solid solution strengthening. Carbon also improves the stress corrosion resistance of austenitic stainless steels rolled in high chloride concentrations.

However, it should also be noted that in the rolling stock of austenitic stainless steel sheets, carbon is also often regarded as a harmful element, mainly because of some conditions in the corrosion resistance application of stainless steel rolling (such as welding or After high temperature heating at 450~850℃), carbon will form high-chromium Cr23C6-type carbon compounds with chromium in stainless steel to form local chromium depletion, which greatly reduces the corrosion resistance of stainless steel, especially the resistance to intergranular corrosion.

Other experimental results have also shown that carbon even increases the probability of chromium's pitting corrosion tendency in austenitic stainless steel sheets. It is precisely because of the harmful effect of carbon that not only the carbon content should be controlled as low as possible in the rolling and smelting process of austenitic stainless steel, but also the carbonization of the rolling surface of stainless steel should be avoided in the subsequent hot, cold working and heat treatment processes and to prevent the precipitation of chromium carbides.

For more information about SS Sheet ASTM 201 304 316L Cold Rolled 2B BA HL 8K Finish Stainless Steel Plate, we are glad to answer for you.