Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

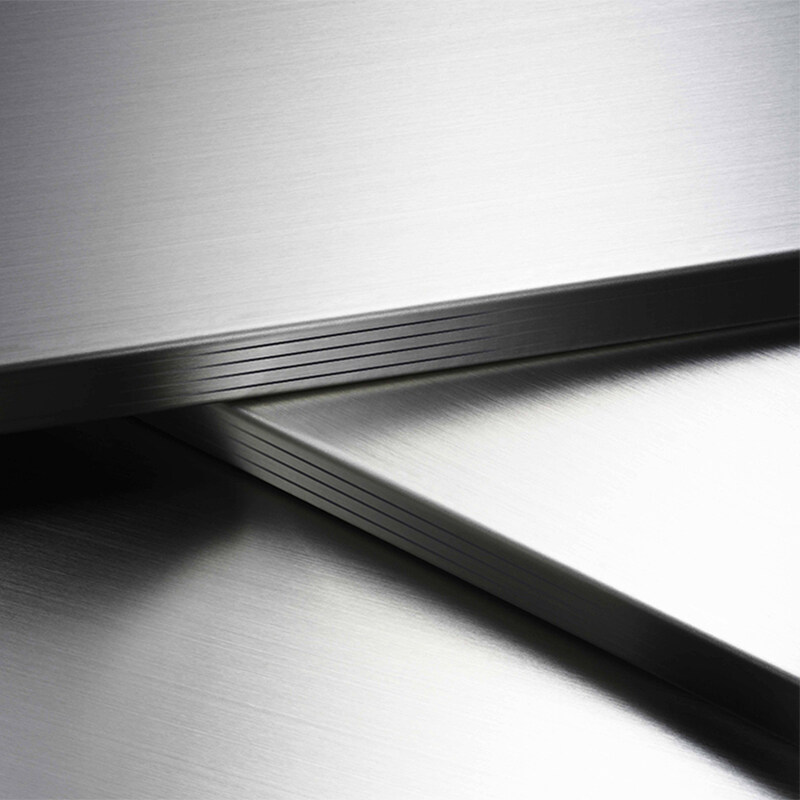

Custom 201 Stainless Steel Forming coil roll

High-quality stainless steel forming coil roll is perfect for custom sheet metal fabrication. Made from 201 stainless steel, it is strong, durable, and corrosion-resistant, providing excellent formability and weldability, making it ideal for a variety of projects. The coil roll is easy to work with and can be cut, bent, and shaped to fit any application, perfect for creating intricate designs and shapes. With its superior strength and corrosion resistance, this coil roll is sure to last for years to come.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

The Custom Sheet Metal Stainless Fabricating 201 Stainless Steel Forming Coil and Roll is tough, long-lasting, and resistant to rust, making it perfect for a range of projects. It’s easy to manipulate and can be cut, bent, and molded to fit any purpose, making it great for creating intricate designs and shapes.

Shock Resistance:

201 stainless steel is highly resistant to deformation and cracking when subjected to strong shocks, thanks to its high strength and hardness. This is due to the presence of elements such as chromium, nickel, and molybdenum, which enhance its hardness and corrosion resistance. Additionally, its excellent tenacity and elasticity allow it to absorb energy and quickly recover its original shape when subjected to strong shocks, reducing the risk of damage. As a result, 201 stainless steel is widely used in applications that require resistance to impact, such as in the manufacturing of machinery, automotive parts, and building structures.

Hygienic (No Rust and Patina):

The stainless steel is premium and won’t release any harmful substances that could damage your health. It’s super clean and won’t rust or develop any discoloration, which won’t affect its chemical or physical properties.

Long Life (40 years of Use):

Generally speaking, 201 stainless steel is built to last and can be used for over 40 years without needing to be replaced. You won’t have to worry about constantly changing it out. Plus, it requires very little maintenance to keep it performing at its best.

Product Parameter:

|

Material |

Stainless Steel |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

GB |

|

Surface Finish |

No.3 |

|

Grade |

300 Series |

|

Length |

10-1200mm or Customized |

|

Thickness |

0.1mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1mm, 2mm, 3mm |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Width |

100-1500mm or Customized |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting, Moulding |

|

Application |

Mechanical Equipment, Electronic Components |

Application:

- Automotive/Automobile Industry: such as vehicle panels and trim components.

- Water Industry: such as water preparation, storage, transportation, purification, regeneration and desalination.

- Construction Industry: such as high-rise building exterior walls, interior and exterior columns, interior and exterior decoration, handrails, floors, wall, elevator siding, doors and windows, curtains and other components.

- Home Appliance Industry: such as automatic washing machine inner pipes, water heater linings, microwave oven inner shells, refrigerator linings and ferritic stainless steel coils.

- Environmental Protection Industry: such as waste incinerators and wastewater treatment.

- Industrial Facilities: in the fields of chemistry, petrochemicals, chemical fibers, paper, food, medicine, energy (nuclear power, thermoelectricity, fuel cells).

Application of stainless steel coil in different industries

From the analysis of the stainless steel coil application industry, the automotive industry is currently the fastest growing stainless steel coil application field. Stainless steel coils are also widely used in public transportation such as buses, subways and high-speed rail vehicles.

Automotive/Automobile industry

This is currently the fastest growing stainless steel coil application. The use of high-strength stainless steel coils to manufacture the body structure can greatly reduce the weight of the vehicle itself and enhance the strength of the body structure. The use of stainless steel coils on vehicle panels and trim components can reduce maintenance costs. In addition, stainless steel coils have the advantage of being resistant to chloride ion corrosion and heat resistance due to the exhaust system of the car. The automotive industry is the focus of development in the application of stainless steel coils.

Water industry

The problem of water contamination during storage and transportation has become an increasingly important issue. A large number of practices have proved that stainless steel coils are the best choice for the water industry, such as water preparation, storage, transportation, purification, regeneration and desalination. Its advantages are: corrosion resistance, shock resistance, water saving, hygienic (no rust and patina), light weight (1/3 reduction), less maintenance, long life (40 years of use), low life cycle cost (LCC) ) It is a green material that can be recycled and reused.

Construction industry

It is one of the earliest fields of stainless steel coil application. In terms of architectural decoration, stainless steel coils are currently mainly used for high-rise building exterior walls, interior and exterior columns, interior and exterior decoration, handrails, floors, elevator siding, doors and windows, curtains and other components. wall. Surface treatment, coloring, and coating stainless steel coils solve the problems of fingerprints after touching, and further expand the application scope of stainless steel coils. Japan has developed various stainless steel coil roofing materials, such as high-chromium and medium-chromium ferrites and various coated sheets with better corrosion resistance.

Home appliance industry

In the household appliance industry, stainless steel coils are widely used in automatic washing machine inner pipes, water heater linings, microwave oven inner shells, refrigerator linings and ferritic stainless steel coils. Western Europe has a large percentage of domestic electric stainless coils, and Asia's usage is generally lower than Japan's approach to European standards.

Environmental protection industry

Industrial waste gas, waste and sewage treatment plants need to be made of stainless steel coils. In the flue gas desulfurization process, in order to resist the corrosion of sulfur dioxide, chloride ions and iron ions, duplex stainless steel coils and high-grade austenitic stainless steel coils are required in absorption towers, coolers, pumps, valves, flue pipes, and so on. Facilities such as waste incinerators and wastewater treatment require high-performance stainless steel coils.

Industrial facilities

The proportion of stainless steel coils used in industrial facilities in developed countries is generally up to 15%-20%, and the current application ratio in China is still small. This is partly due to the introduction of industrial equipment and partly because Chinese materials have not yet been adopted. Stainless steel coils are required in the fields of chemistry, petrochemicals, chemical fibers, paper, food, medicine, energy (nuclear power, thermoelectricity, fuel cells).

For more information about Custom sheet metal stainless fabricating 201 301 304 316 Stainless Steel Forming coil roll, we are glad to serve you.