Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

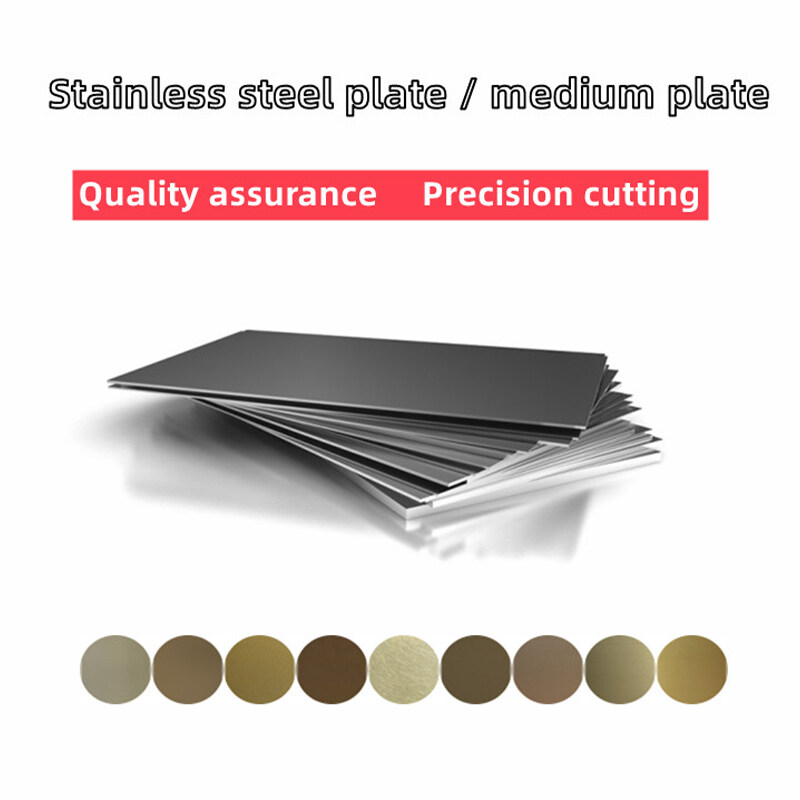

Hot Rolled 201 Black Stainless Steel Plate

Hot-rolled steel plate is made of stainless steel sheet 201, providing superior strength and durability. It is black in color and has a smooth finish, making it ideal for a variety of applications. It is resistant to corrosion and has excellent formability, making it easy to shape into the desired shape.This hot-rolled steel plate is an excellent choice for projects requiring a strong and reliable material.

-

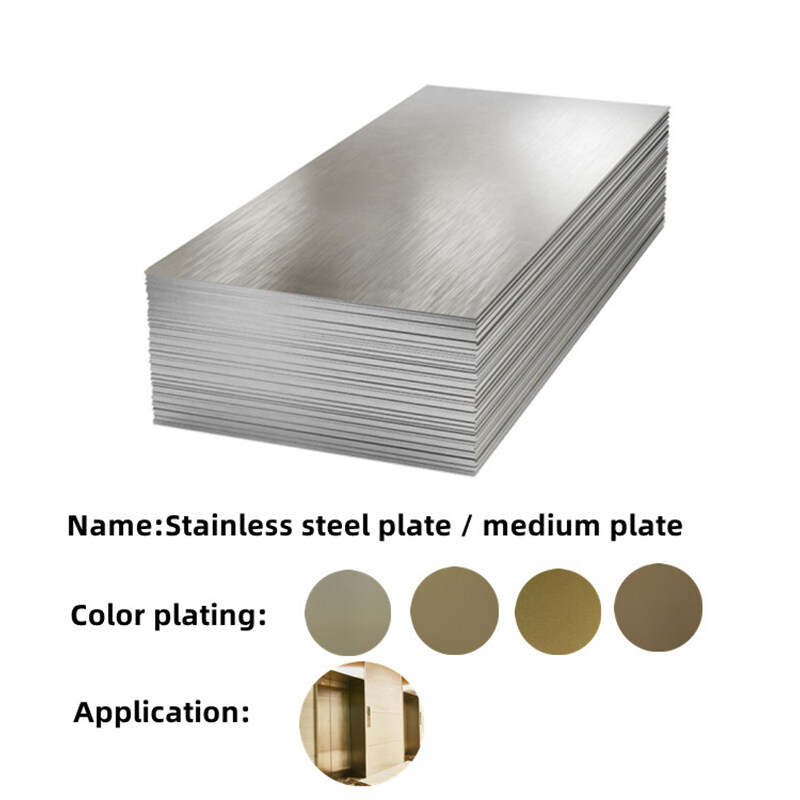

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

The Stainless Steel Sheet 201 Black Sheet Metal Hot Rolled Steel Plate offers superior strength and durability. Its sleek black color and smooth finish make it perfect for a wide range of applications. It’s highly resistant to corrosion and has excellent formability, making it easy to shape into any desired form. You can even customize it to meet your specific needs.

Fit ASTM Standard:

In the aerospace and defense (A&D) industry, ASTM is the most important reference standard. That’s why we ensure that every aspect of our manufacturing process, from the materials we use to the technology we employ, adheres to strict manufacturing rules to ensure the highest quality possible. We take quality seriously and understand the importance of meeting industry standards to ensure our products meet the needs of our customers.

Superior Strength and Durability:

The 201 stainless steel black sheet metal is highly regarded for its exceptional strength and durability, making it a top choice for a variety of applications. Its robust construction ensures it can withstand heavy use and harsh conditions, making it a reliable material for industrial and commercial settings.

Sleek Black Color:

The 201 black sheet metal has a sleek and modern appearance that makes it perfect for decorative purposes. Its black color gives it a stylish and contemporary look that can enhance the aesthetic appeal of any project.

Versatile for Wide Application:

Whether you’re using it for interior design, architectural accents, or artistic installations, the 201 black sheet metal is a versatile material that can add a touch of sophistication to any space. Its unique color and smooth finish make it a popular choice for those who want to create a bold and eye-catching statement.

Product Parameter:

|

Material |

201/304/304L/316/316L/430 Stainless Steel Sheet |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

ASTM |

|

Surface Finish |

BA |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Grade |

300/ 400 Series |

|

Length |

Customized |

|

Thickness |

0.3-120mm or Customized |

|

Certification |

RoHS, JIS, ISO9001 |

|

Width |

10-1500mm or As Request |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Construction/ Decorationchemical Equipment |

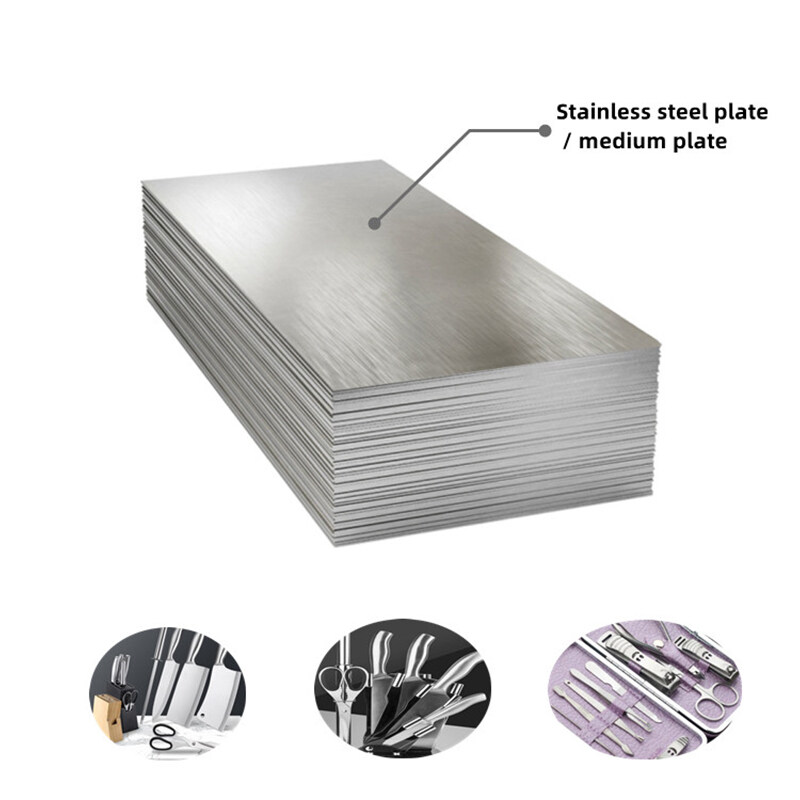

Application:

·Construction: such as roofing, siding, and gutters.

·Manufacturing: for the production of appliances, automotive parts, and machinery.

·Decorative Purposes: such as interior design, architectural accents, and artistic installations.

·Food Processing: in the food processing industry.

·Marine applications: such as boat building and dock construction.

Hot rolled steel plate

By definition, steel ingots or billets are difficult to deform at room temperature and difficult to process. Generally, they are heated to 1100-1250 °C for rolling. This rolling process is called hot rolling. The temperature of the hot-rolled sheet is high, so the deformation resistance is small, and a large amount of deformation can be achieved. Taking the rolling of steel plates as an example, the thickness of the continuous casting slab is generally about 230mm, and after rough rolling and finishing rolling, the final thickness is 1~20mm. At the same time, due to the small width-to-thickness ratio of the steel plate, the dimensional accuracy requirements are relatively low, and the plate shape problem is not easy to occur, and the main control is to control the crown. If there is a requirement for the structure, it is generally realized by controlled rolling and controlled cooling, that is, controlling the opening temperature, finishing rolling temperature and coiling temperature of the finishing rolling to control the microstructure and mechanical properties of the strip.

Cold rolled steel plate

Cold rolling is a steel sheet in which the steel sheet is further thinned to a target thickness below the recrystallization temperature under room temperature conditions. Compared with hot rolled steel, the thickness of cold rolled steel is more accurate, and the surface is smooth and beautiful. Cold-rolled sheets generally do not have a heating process before rolling. However, due to the small thickness of the strip, it is easy to have problems with the shape of the strip. Moreover, the finished product is obtained after cold rolling. Therefore, in order to control the dimensional accuracy and surface quality of the strip, many complicated processes are used.

The cold rolling production line is long, the equipment is many, and the process is complicated. With the improvement of users' requirements for strip dimensional accuracy, shape and surface quality, the control model, l1 and l2 systems, and shape control methods of cold rolling mills are more than those of hot rolling. Moreover, the temperature of the roll and the strip is also one of the more important control indicators. By definition, the ingot or billet is difficult to deform at room temperature and difficult to process. Most of the steel is rolled by hot rolling. However, because iron oxide scale is easily formed on the surface of the steel at high temperature, the surface of the hot-rolled steel is rough and the size fluctuates greatly. Therefore, the steel with smooth surface, accurate size and good mechanical properties is required. produced by rolling method.

The difference between hot rolling and cold rolling

1.Appearance and surface quality: Since the cold plate is obtained after the cold rolling process of the hot plate, and some surface finishing will be carried out at the same time, the cold plate is better than the hot plate in terms of surface quality (such as surface roughness). It came well, so if there are higher requirements for the coating quality of the product, such as post-painting, generally choose the cold plate, and the hot plate is divided into pickling plate and non-pickling plate. Normal metallic color, but not cold rolled, so the surface is not as high as the cold plate. The surface of the non-pickling plate usually has an oxide layer on the surface, which is black, or there is a black layer of iron tetroxide, and if the storage environment is not good, it will usually bring some embroidery.

2.Performance: In general, the mechanical properties of the hot plate and the cold plate are considered to be indistinguishable in the project, although the cold plate has a certain degree of work hardening during the cold rolling process, (but it does not rule out that the mechanical properties are strictly required. , then it needs to be treated differently), the yield strength of the cold plate is usually slightly higher than that of the hot plate, and the surface hardness is also higher, depending on the degree of annealing of the cold plate. But no matter how annealed, the strength of cold plate is higher than that of hot plate.

3.Forming performance: Since the performance of cold and hot plates is basically not too different, the influencing factors of forming performance depend on the difference in surface quality. Since the surface quality is better from cold plates, generally speaking, the same material is used. Steel plate, cold plate has better forming appearance than hot plate.

For more information about Belt stainless steel sheet ss400 q235 q345 ms iron black sheet metal hot rolled steel plate, we are glad to serve you.