Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

301 Stainless steel coil strip belt Factory

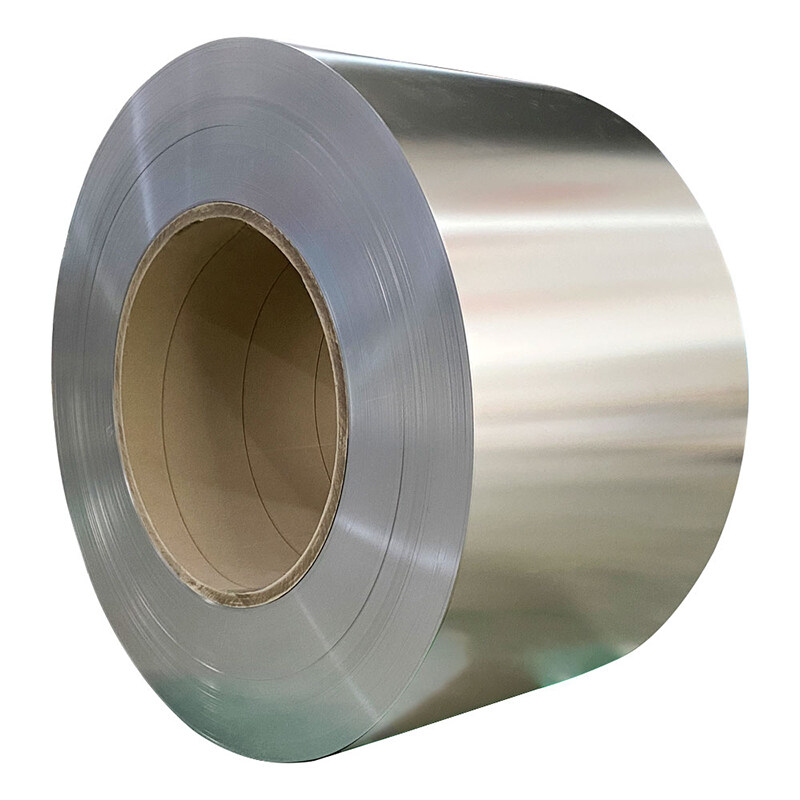

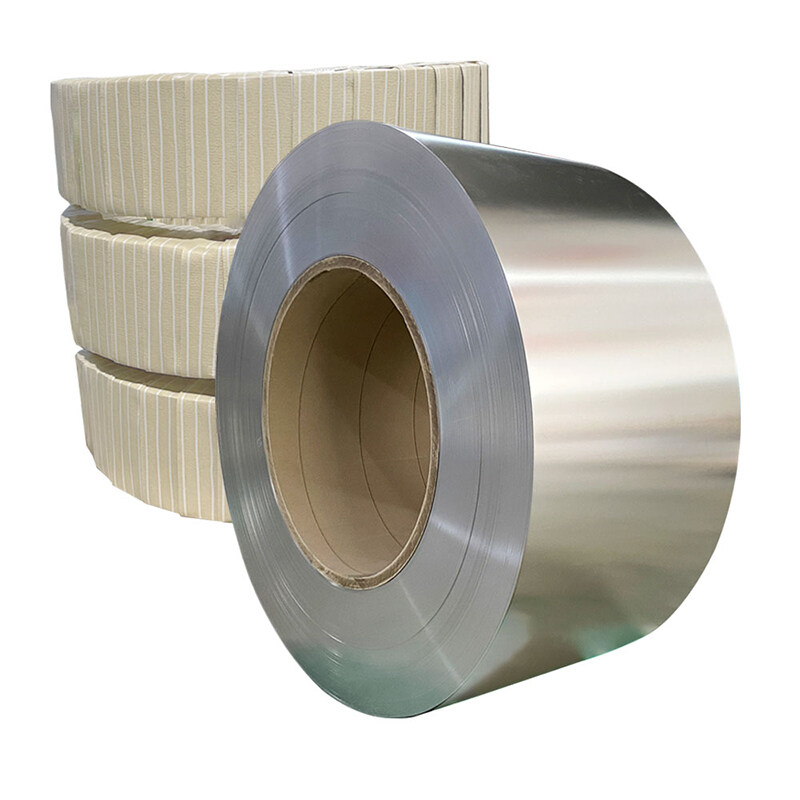

This high-quality, low-price 301 stainless steel coil strip belt is perfect for a variety of industrial and commercial applications. It is made of durable stainless steel with superior corrosion resistance and is designed for long-term use. The coil strip belt is flexible and easy to install, and its smooth surface ensures minimal friction during operation. With its low price and high quality, this stainless steel coil strip belt is an excellent choice for any project.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

The High Quality Low Price 301 Stainless Steel Coil, Strip, and Belt is crafted from durable stainless steel that boasts superior corrosion resistance, ensuring long-lasting use. The coil strip belt is flexible and easy to install, and its smooth surface minimizes friction during operation. With its unbeatable combination of affordability and quality, this stainless steel coil strip belt is the perfect choice for any project.

High Dimensional Accuracy (Up to ± 0.1mm):

We offer a wide range of stainless steel products with various materials and complete specifications to choose from. Our products are incredibly accurate, with a detailed accuracy of up to ± 0.1mm, ensuring minimal errors.

Good Surface Quality and Brightness:

The 301 stainless steel coil boasts excellent surface quality, making it perfect for processing any item you need. Plus, it’s bright and doesn’t require any additional polishing treatment, so you can use it right away. The high-quality surface and brightness are a testament to the superior quality of our product!

Resist Atmospheric Oxidation and Corrosion:

Stainless steel is known for its ability to resist rust caused by atmospheric oxidation. However, it can still corrode in mediums containing acid, alkali, and salt. The level of corrosion resistance in a stainless steel coil strip belt depends on its chemical composition, protective state, service conditions, and environmental medium type. While not all types of stainless steel can resist corrosion and rust in any environment, they are still highly resistant to rusting.

Adapt to Complex Processing Conditions:

Our 301 stainless steel strip is incredibly versatile and can adapt to complex processing conditions, such as stamping, rolling, bending, and punching. This makes it the perfect choice for a wide range of applications!

Product Parameter:

|

Material |

301/ 304/ 304L/ 316/ 316L Stainless Steel Sheet |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

GB |

|

Certification |

API, CE, RoHS, JIS, GS, ISO9001 |

|

Surface Finish |

BA |

|

Grade |

300 Series |

|

Length |

Customized |

|

Thickness |

0.3-3mm or Customized |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Width |

1-3mm or Customized |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting, Moulding |

|

Application |

Electronics, Automobiles, Construction and Other Industries |

This is our high quality low price 301 304 304l 316 316l Stainless steel coil strip belt.

Advantages of stainless steel coil strip belt

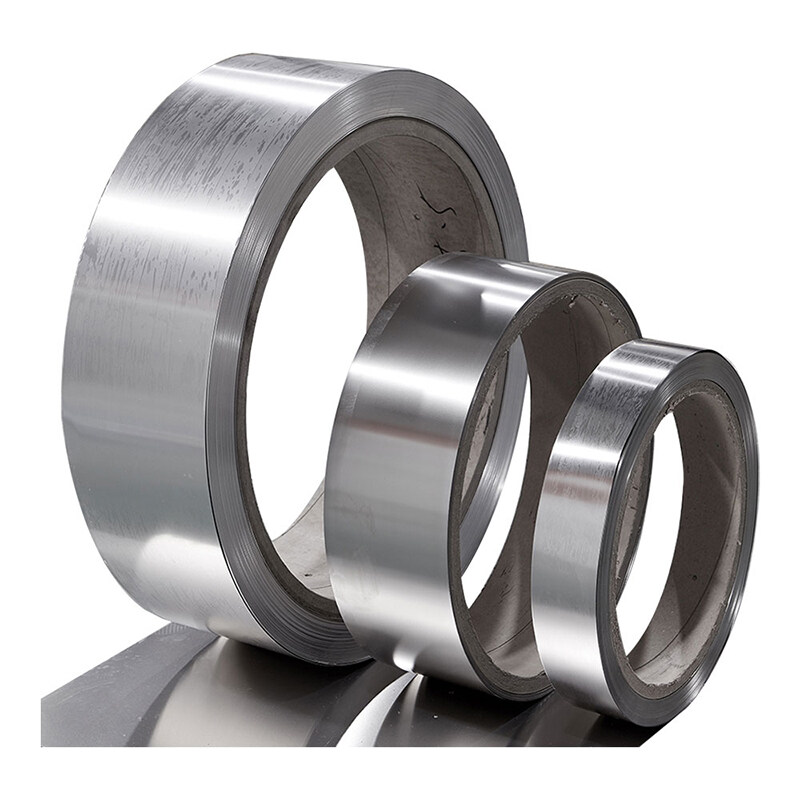

Stainless iron coil is simply an extension of ultra-thin stainless steel iron. It is mainly a narrow and long steel plate produced to meet the needs of industrialized production of various metal or mechanical products in different industrial sectors. Stainless steel tape is also widely used in our daily life. Today we will introduce the advantages of stainless steel tape in detail.

Stainless steel coil strip belt is also called coil material, coil plate, coil plate, and there are many hardness.

1.Complete product specifications and various materials;

2.High dimensional accuracy, up to ± 0.1mm;

3.Good surface quality and brightness;

4.It has strong corrosion resistance, high tensile strength and fatigue resistance;

5.Stable chemical composition, pure steel and low inclusion content;

6.The package is intact. stainless steel coil strip belt and wire rod has good metallographic structure and average performance. The chemical composition of stainless steel coil strip belt is stable and average, with a small bias, and the steel is pure. The content of S, P, N and other harmful elements and inclusions in stainless steel coil strip belts is low, ensuring safety. stainless steel coil strip belt has high hard wire ratio, high fine wire ratio and high quality ratio. The stainless steel coil strip belt material has good appearance quality. The appearance of the bar is free of sand holes and black spots, and the straightness is excellent.

Stainless steel coil strip belt is mainly reflected in corrosion resistance and heat resistance, followed by the hardening phenomenon of easy stamping and no heat treatment. Stainless iron has the ability to resist atmospheric oxidation - that is, rust resistance, but also has the ability to corrode in the medium containing acid, alkali and salt - that is, corrosion resistance. However, the corrosion resistance of stainless steel coil strip belt varies with its chemical composition, protective state, service conditions and environmental medium type. Therefore, not any kind of stainless iron can resist corrosion and rust in any environment, but it is not easy to rust.

Stainless steel tape has been widely used in heavy industry, light industry, household goods industry, architectural decoration and other industries. Its production has brought a lot of convenience to modern industry and achieved a qualitative leap in industry.

Stainless steel coil strip belt keeps improving

Stainless steel coil strip belts not only have perfect surface quality, but also can adapt to complex processing conditions (such as stamping, rolling, bending, punching, etc.). At the same time, it also has other remarkable characteristics, such as surface wear resistance, strong anti-aging ability, anti fingerprint and a series of excellent characteristics.

Generally, stainless steel coil strip belts can only be bent at a small angle. The higher the hardness is, the greater the elasticity is, the more brittle the material is. If the bending angle is large, it is easier to break. Cold rolled stainless steel coil strip belts are hard steel coils that have not been recrystallized and annealed. Customers often ask about the difference in bending performance, especially those who do metal stamping and stretching parts. Some require horizontal bending, some require longitudinal bending, and some require bidirectional bending. Bending in different directions is affected by the bending performance of cold-rolled stainless steel coil strip belts.

The grains of cold-rolled stainless steel coil strip belt are narrow and long, and the rolling direction of steel coil is generally horizontal, so the rolled grains are narrow and long in the figure below. When bending horizontally, they are not easy to break due to the influence of grain arrangement. When bending longitudinally, there are obvious slits, which are easier to break.

In fact, the bend diameter of stainless steel coil strip belt is very important to the bending result. Smaller bend diameter is easier to crack, such as bending 90 degrees and 180 degrees is completely different. There are many reasons that affect the bending results of stainless steel coil strip belts, such as grain boundary deformation, segregation, banded structure, etc., which can not be ignored.