Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

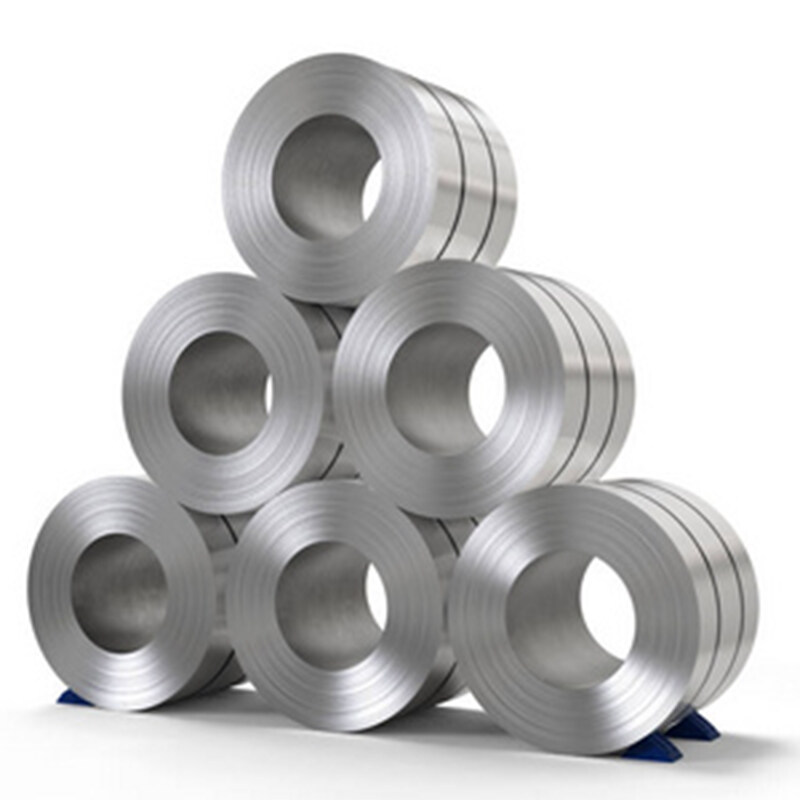

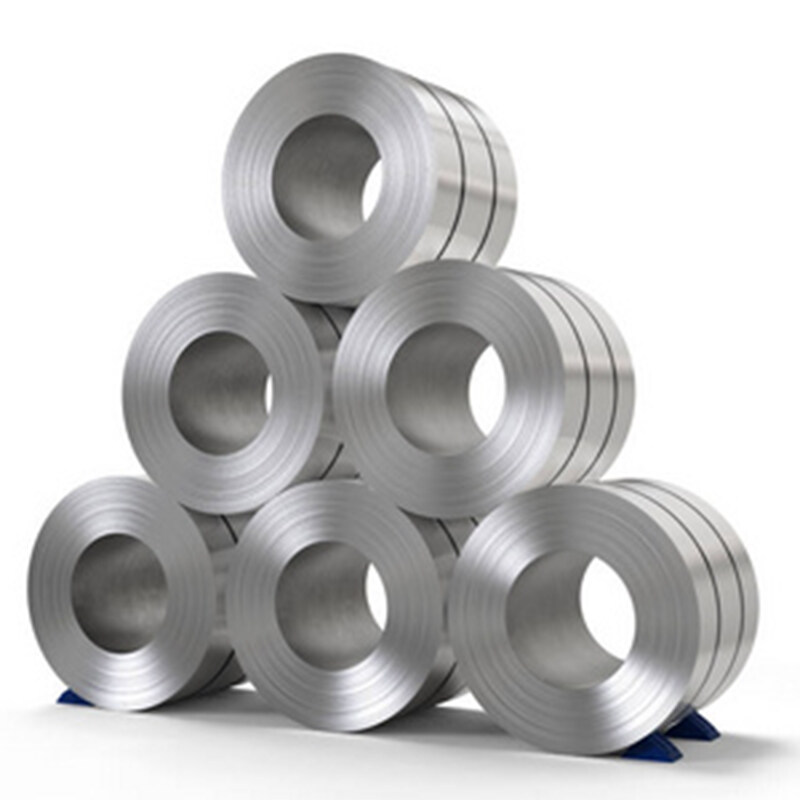

The Art of Wholesale Stainless Steel Coil 304

Introduction:

In the realm of metallurgy, SS304, commonly known as 304 Stainless Steel Coil, stands as a luminary, seamlessly blending durability, corrosion resistance, and versatility. As we celebrate the one-year milestone of this informative exploration, let's delve into the intricacies of its manufacturing processes and unveil the artistry that goes into creating this sought-after stainless steel variant.

I. The Symphony of Composition:

At the heart of Wholesale Stainless Steel Coil 304 lies a meticulously crafted alloy, a harmonious blend of iron, chromium, nickel, and other trace elements. This composition not only bestows remarkable corrosion resistance but also imparts the coil with formidable mechanical properties. From the perspective of material science, this alloy is a masterpiece, balancing strength and formability with a touch of aesthetic appeal.

II. The Alchemy of Manufacturing:

A. Raw Material Selection: The journey commences with the careful selection of high-quality stainless steel, akin to choosing the finest ingredients for a culinary masterpiece. This ensures that the end product meets stringent industry standards and caters to diverse applications across construction, automotive, and kitchenware.

B. Melting and Casting: In the crucible of induction furnaces, the alloy undergoes a transformative phase, akin to the forging of steel in ancient blacksmith shops. This process, informed by metallurgical principles, ensures the homogeneity of the alloy and sets the foundation for its exceptional properties.

C. Hot Rolling: Here, the alloy encounters the dance of heat and pressure, akin to the forging of a sword on an anvil. Precision in temperature control and pressure parameters shapes the coil, giving it the required thickness and structural integrity.

III. The Elegance of Cold Rolling:

As the coil progresses, cold rolling adds finesse to its form. This stage, reminiscent of a sculptor refining their creation, imparts a smooth surface finish, elevating the aesthetic appeal of the stainless steel coil. This dual focus on functionality and aesthetics caters to the diverse needs of industries ranging from architecture to consumer goods.

IV. The Rituals of Annealing and Pickling:

The coil, akin to a phoenix, undergoes a transformative rebirth through annealing—a heat treatment that relieves stresses and enhances its mechanical properties. Subsequently, the acid pickling process, resembling the purification rituals of ancient artefacts, removes oxides, ensuring the pristine quality of the stainless steel surface.

V. Precision in Cutting and Slitting:

Much like a tailor crafting bespoke garments, the stainless steel coil undergoes precision cutting and slitting. These techniques cater to the diverse demands of industries, providing coils of various widths and dimensions. The flexibility offered by these processes aligns with the dynamic needs of construction, manufacturing, and precision engineering.

VI. The Vigil of Inspection and Quality Assurance:

In the final stages, the coil undergoes meticulous inspection, resembling a watchmaker's scrutiny of intricate timepieces. Visual inspections unearth any surface defects, while mechanical and non-destructive testing techniques ensure the coil meets rigorous quality standards. This stringent quality assurance process is paramount to upholding the reputation of Wholesale Stainless Steel Coil 304 across industries.

VII. Packaging and Storage Symphony:

The final act involves packaging the stainless steel coils with a keen eye on preventing corrosion, akin to preserving ancient artefacts for posterity. Proper labelling enhances identification, ensuring that each coil finds its purpose in diverse applications. Storage recommendations, informed by materials science, preserve the integrity of the coils until they are ready to embark on their journey in various industrial domains.

VIII. Market Dynamics:

Within the global stainless steel market, the demand for wholesale stainless steel coil 304 reflects a nuanced interplay of economic, technological, and environmental factors. Emerging applications, such as in sustainable architecture and renewable energy, highlight the coil's adaptability to evolving market needs.

Conclusion:

In conclusion, the manufacturing journey of Wholesale Stainless Steel Coil 304 is a testament to the synergy of art and science. From the alchemy of alloy composition to the precision of cutting and the vigil of quality assurance, each step contributes to the creation of a stainless steel masterpiece. As we celebrate one year of exploration, let us continue to appreciate the craftsmanship that shapes this indispensable material, transcending industries and leaving an indelible mark on the world.