Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

News

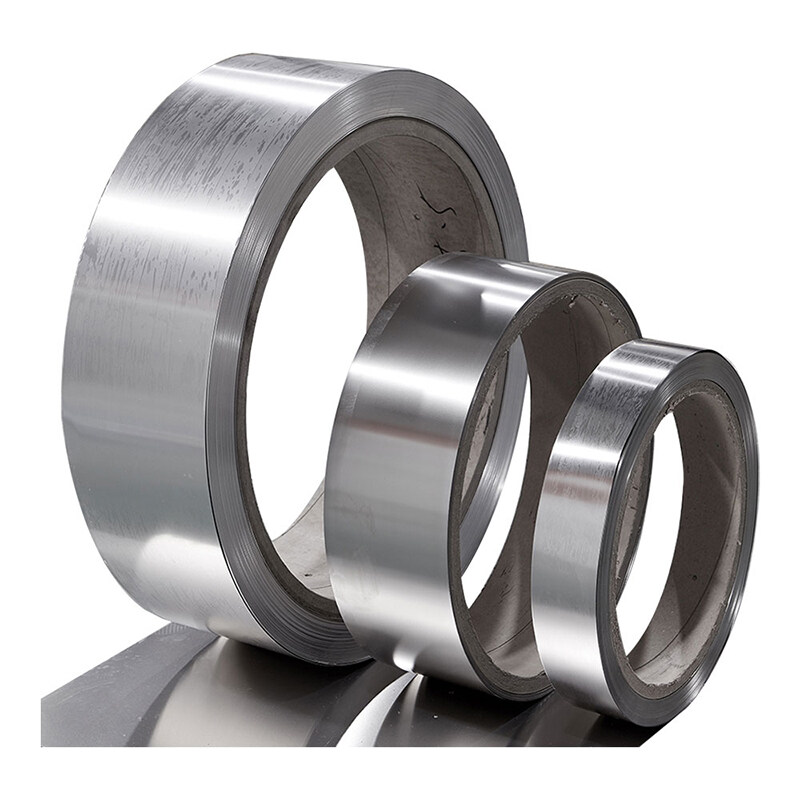

Cold Rolled Stainless Steel Coil Strip

2025-03-07 11:57:52

When you think about the backbone of modern manufacturing, you might picture massive machines or high-tech robotics. But there's another hero that often flies under the radar—cold rolled stainless steel coil strip. Ever wondered why this material is such a game-changer in the manufacturing world? Let's dive in and explore what makes it so special, how it's made, and why it's a must-have for countless industries.

What Is Cold Rolled Stainless Steel Coil Strip?

Cold rolled stainless steel coil strip is a versatile and highly engineered material that plays a crucial role in various industries. But what exactly is it, and how does it differ from its hot-rolled counterpart?

A Quick Comparison: Cold Rolled vs. Hot Rolled

Imagine you're baking a cake. Hot rolling is like mixing your ingredients quickly at a high temperature—efficient but not as precise. Cold rolling, on the other hand, is like carefully measuring and mixing each ingredient at a lower temperature. The result is a more refined and precise product.

Hot-rolled stainless steel is produced by rolling the steel at high temperatures, which gives it a rougher surface and less precise dimensions. Cold rolling, however, involves rolling the steel at room temperature. This process not only improves the surface finish but also enhances the mechanical properties of the material.

Key Characteristics

Cold rolled stainless steel coil strip has some standout features that set it apart:

-

Surface Finish: It boasts a smooth, shiny surface that's perfect for applications where aesthetics matter. Think stainless steel kitchenware or sleek automotive parts.

-

Thickness: The precision rolling process allows for extremely thin and uniform thicknesses, often down to just a few millimeters. This makes it ideal for applications where weight and space are critical.

-

Mechanical Properties: Cold rolling increases the material's strength and hardness, making it more durable and resistant to wear and tear.

Why Is It So Popular?

Alright, let's get down to the nitty-gritty. Why is cold rolled stainless steel coil strip such a big deal? The answer lies in its incredible versatility and the numerous advantages it offers.

Better Surface Finish

The smooth, polished surface of cold rolled stainless steel isn't just pretty—it's practical. This finish reduces the risk of corrosion and makes cleaning easier, which is essential in industries like food processing and medical equipment manufacturing.

Higher Precision

When you need parts that fit perfectly, cold rolled stainless steel coil strip is your go-to material. Its precise dimensions and uniform thickness mean fewer errors and less waste during production. This level of precision is crucial in industries like automotive and aerospace, where even the slightest deviation can have significant consequences.

Improved Strength

Cold rolling enhances the material's strength without adding extra weight. This makes it perfect for applications where you need a lightweight yet strong material. For example, in the automotive industry, using cold rolled stainless steel can help reduce the overall weight of a vehicle while maintaining its structural integrity.

Real-World Applications

Cold rolled stainless steel coil strip is everywhere, even if you don't realize it. It's used in everything from the shiny hood of your car to the stainless steel cutlery in your kitchen. In the medical field, it's a key component in surgical instruments and implants, thanks to its biocompatibility and corrosion resistance.

How Is Cold Rolled Stainless Steel Coil Strip Made?

Now that we know why it's so great, let's take a peek behind the scenes at how it's made. The process might sound technical, but I promise it's fascinating.

Annealing

The journey begins with annealing, where the steel is heated and then slowly cooled. This step softens the material, making it easier to work with. Think of it like warming up a piece of clay before shaping it.

Pickling

Next up is pickling. No, it's not about making pickles! This step involves removing any surface impurities or oxides using an acid solution. It's like giving the steel a deep cleanse to ensure a pristine surface.

Rolling

The real magic happens during the rolling process. The steel is passed through a series of rollers at room temperature, gradually reducing its thickness. This step not only achieves the desired dimensions but also enhances the material's strength and hardness.

Final Touches

After rolling, the strip is often subjected to additional processes like leveling and slitting to ensure it meets the required specifications. By the end, you have a high-quality, precision-engineered cold rolled stainless steel coil strip ready for use.

Choosing the Right Cold Rolled Stainless Steel Coil Strip for Your Needs

With so many options out there, how do you choose the perfect cold rolled stainless steel coil strip for your project? Here are some practical tips to help you make the right decision:

Consider the Grade

-

Austenitic Grades: These are the most common and offer excellent corrosion resistance and formability. They're perfect for applications like kitchenware and chemical processing equipment.

-

Ferritic Grades: These are more magnetic and offer good corrosion resistance at a lower cost. They're often used in automotive parts and household appliances.

-

Martensitic Grades: These are the hardest and strongest but less formable. They're ideal for cutting tools and surgical instruments.

Think About Thickness

-

Thin Strips: For applications where weight and space are critical, such as aerospace components or electronic devices, thinner strips are the way to go.

-

Thicker Strips: If you need more strength and rigidity, like in structural components or heavy machinery, thicker strips will be more suitable.

Surface Finish

-

Bright Annealed: If you need a shiny, reflective surface for aesthetic or functional purposes, bright annealed finishes are ideal.

-

No. 4 Finish: This is a popular choice for architectural applications and kitchenware, offering a smooth, brushed appearance.

Practical Advice

-

Always consult with a trusted supplier to ensure you're getting the right material for your specific needs.

-

Consider factors like cost, availability, and lead times when making your decision.

If you're looking for a high-quality cold rolled stainless steel coil strip that meets industrial standards, Qichen Precision Alloy Materials offers a range of options with superior precision and durability. Their products are designed to solve common industry challenges, ensuring you get the best material for your project.

Market Trends & Future of Cold Rolled Stainless Steel

The world of manufacturing is constantly evolving, and cold rolled stainless steel coil strip is no exception. Let's take a look at some of the current trends and what the future holds.

Growing Demand

As industries continue to innovate and push the boundaries of what's possible, the demand for high-quality, precision materials like cold rolled stainless steel coil strip is only going to increase. From electric vehicles to renewable energy projects, this material is essential for creating the next generation of products.

New Technologies

Advancements in rolling technology and surface treatment processes are making cold rolled stainless steel even better. For example, new rolling techniques are allowing for even thinner and more precise strips, while advanced surface treatments are enhancing corrosion resistance and durability.

Sustainability Trends

In an era where sustainability is a top priority, the stainless steel industry is stepping up. Modern production processes are becoming more energy-efficient, and recycling rates for stainless steel are on the rise. This means that choosing cold rolled stainless steel coil strip isn't just good for your project—it's also good for the planet.

Wrapping Up

Cold rolled stainless steel coil strip is a crucial material in modern manufacturing due to its precision, strength, and versatility. It is widely used in various industries, including automotive, kitchen appliances, and medical equipment. If you need high-quality cold rolled stainless steel coil strip, Qichen Precision Alloy Materials offers reliable products and expert guidance.

Prev Post

Next Post

Contact us