Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

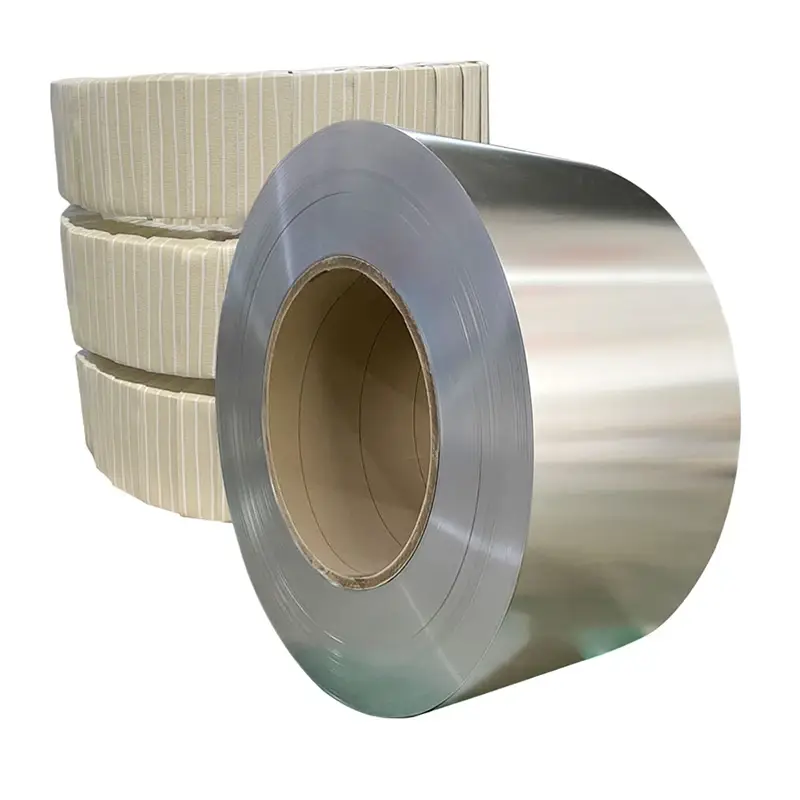

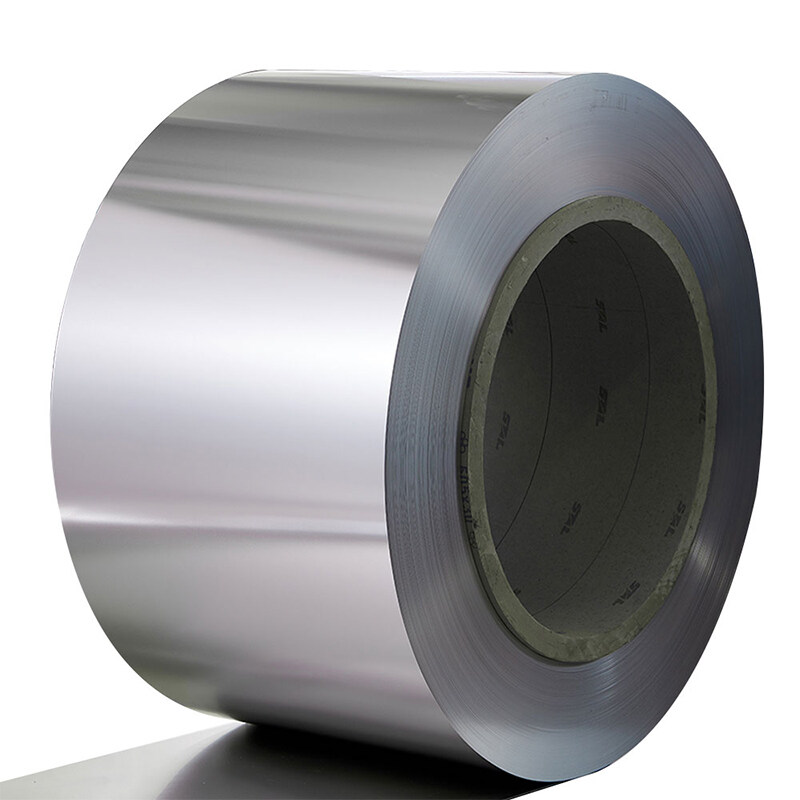

Custom 304 & 304L Stainless Steel Coil

Stainless steel coils, particularly the 304 and 304L grades, are the backbone of numerous industries due to their exceptional corrosion resistance, strength, and versatility. Whether it's for architectural applications, automotive parts, kitchen equipment, or industrial components, custom stainless steel coils play a pivotal role. This comprehensive guide will explore the features of 304 and 304L stainless steel coils, their manufacturing process, and the factors to consider when choosing a supplier.

Understanding 304 & 304L Stainless Steel Coils

304 and 304L stainless steel coils are austenitic, which means they possess excellent toughness and weldability. The "L" in 304L denotes a lower carbon content, making it more resistant to intergranular corrosion, a phenomenon that can occur in the presence of welding heat or other heat sources. This makes 304L particularly suitable for applications where welding is involved or in environments where stress corrosion cracking is a concern.

Applications of 304 & 304L Stainless Steel Coils

The versatility of these coils is evident in their wide range of applications:

- Automotive Industry: Used for manufacturing exhaust systems, fuel lines, and other automotive components that require high strength and corrosion resistance.

- Construction: Commonly used in the construction of skyscrapers, bridges, and other structures where both strength and aesthetics are required.

- Kitchenware: Due to its resistance to staining and corrosion, 304 and 304L stainless steel are ideal for the production of sinks, cookware, and other kitchen tools.

- Chemical and Pharmaceutical Industries: Used in equipment and containers that come into contact with chemicals and need to maintain their integrity over time.

- Food Processing: The non-reactive nature of these coils makes them perfect for equipment in the food processing industry.

Manufacturing Process of Stainless Steel Coils

The manufacturing process of stainless steel coils involves several key steps:

- Melting: The raw materials, including iron ore, chromium, and other alloying elements, are melted in an electric arc furnace to create a molten mixture.

- Refining: The molten steel is then transferred to an AOD (Argon Oxygen Decarburization) converter or a VOD (Vacuum Oxygen Decarburization) unit to adjust the chemical composition and remove impurities such as carbon and oxygen.

- Casting: The refined steel is cast into slabs, blooms, or billets, which are then cooled and sent to the rolling mill.

- Hot Rolling: The slabs are heated and passed through rollers to reduce their thickness and achieve the desired shape.

- Annealing: The rolled coils are heated to a specific temperature to relieve internal stresses and improve their mechanical properties.

- Cold Rolling: To achieve a smoother surface and tighter tolerances, the coils undergo cold rolling, followed by a final annealing process.

- Finishing: The coils may be further processed with surface treatments such as pickling, brushing, or polishing to meet specific application requirements.

Choosing the Right Stainless Steel Coil Supplier

When selecting a supplier for custom 304 and 304L stainless steel coils, consider the following factors:

- Quality Assurance: Ensure the supplier adheres to international quality standards and provides certification for the materials supplied.

- Customization Capabilities: Choose a supplier that can meet your specific requirements regarding dimensions, surface finish, and tolerances.

- Experience and Reputation: Opt for a supplier with a proven track record in the industry and positive customer feedback.

- Availability and Inventory: A supplier with a wide range of stainless steel coils in stock can ensure timely delivery and meet your production needs.

- Customer Service: Reliable customer service and after-sales support are crucial for addressing any concerns or issues that may arise.

Conclusion

Custom 304 and 304L stainless steel coils are indispensable in various industries due to their unique properties and wide range of applications. Understanding the manufacturing process, knowing the specific requirements for your application, and selecting a reputable supplier are key to leveraging the full potential of these high-performance materials. For more information on stainless steel coils and to find a reliable supplier, consider reaching out to industry leaders like China Baowu Group and Huaxiao Metal , who are committed to providing high-quality stainless steel products and services.