Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

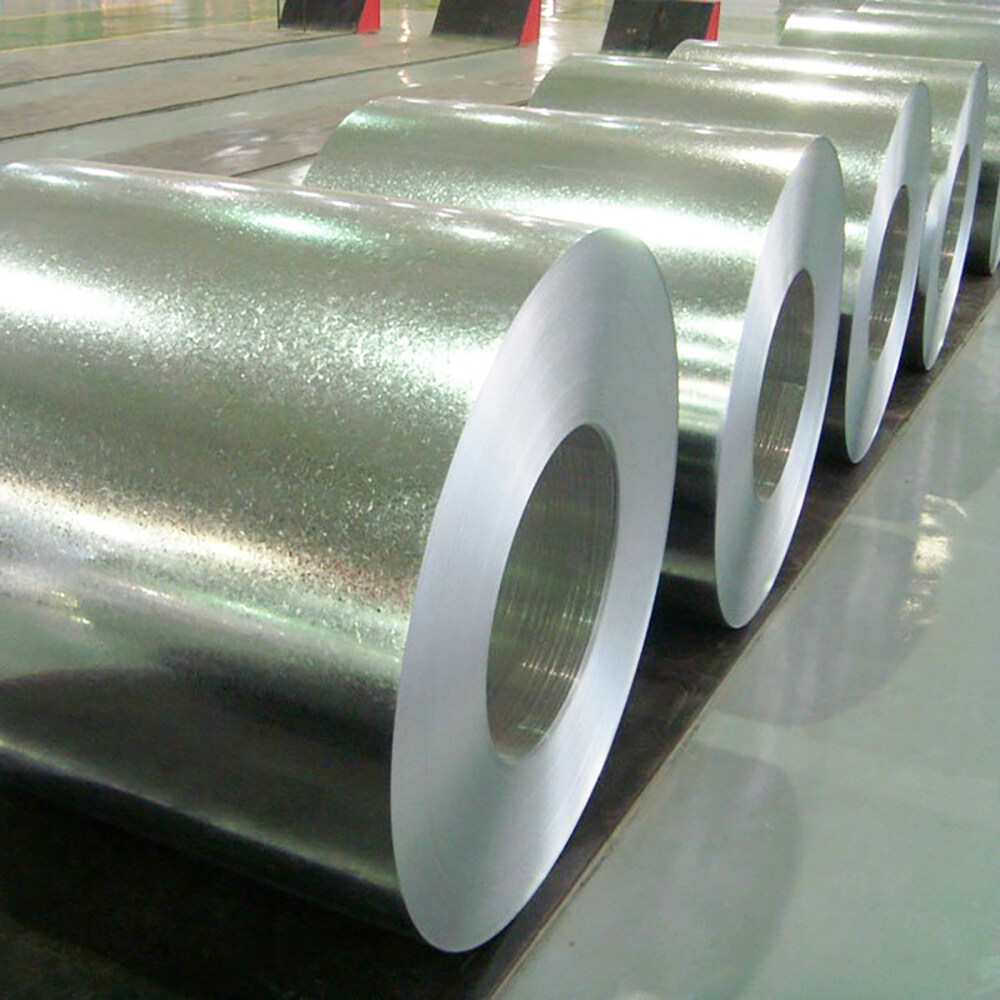

Ppgi Ppgl Pre Painted Coil Factory

"PPGI" and "PPGL" refer to types of pre-painted metal coils, widely used in various applications due to their durability and aesthetic appeal. Here's a detailed look at these materials:

PPGI (Pre-Painted Galvanized Iron):

- Composition: PPGI coils are made of galvanized iron, which is iron coated with a layer of zinc to prevent rusting.

- Paint Coating: These coils are pre-painted, meaning they are coated with layers of paint on both sides in a controlled factory environment. This ensures a uniform and high-quality finish.

- Uses: PPGI is commonly used for roofing, wall panels, and in various interior and exterior building materials. Its rust resistance and aesthetic appeal make it a popular choice in the construction industry.

PPGL (Pre-Painted Galvalume Steel):

- Composition: PPGL is made of Galvalume steel, which is a steel material coated with an alloy of aluminum and zinc. This combination offers enhanced corrosion resistance compared to traditional galvanized steel.

- Paint Coating: Like PPGI, PPGL coils are also pre-painted in a controlled factory setting. This process provides a consistent and durable paint finish.

- Uses: PPGL is often used in environments where corrosion resistance is of high importance, such as in roofing, external cladding of buildings, and in areas with harsh weather conditions.

Key Features:

- Corrosion Resistance: Both PPGI and PPGL offer excellent protection against rust and corrosion, which extends the life of the products they are used in.

- Aesthetic Variety: Available in a wide range of colors and finishes, allowing for customization in architectural designs.

- Durability: The paint coating provides additional protection against the elements, making these materials durable.

- Environmentally Friendly: Both PPGI and PPGL are recyclable, which is beneficial for sustainable building practices.

Installation and Applications:

- These pre-painted coils can be cut and shaped into various forms for different applications.

- They are commonly used in the manufacturing of roofing sheets, wall panels, sandwich panels, and other architectural cladding.

- Due to their aesthetic appeal, they are also used in the production of home appliances and automotive parts.

PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume Steel) pre-painted coils involves detailing the key attributes that are important for these materials. These coils are commonly used in construction, manufacturing, and various industrial applications due to their durability and corrosion resistance. Here's an example of what a specification table for PPGI and PPGL coils might look like:

| Parameter | Specification for PPGI Coils | Specification for PPGL Coils |

|---|---|---|

| Base Metal | Galvanized Iron | Galvalume Steel (Aluminum-Zinc Alloy) |

| Coating Type | Zinc Coating | Aluminum-Zinc Alloy Coating |

| Paint Type | Polyester, SMP, HDP, PVDF, etc. | Polyester, SMP, HDP, PVDF, etc. |

| Thickness | 0.12mm - 2.0mm (commonly) | 0.12mm - 2.0mm (commonly) |

| Width | Up to 1250mm (standard) | Up to 1250mm (standard) |

| Paint Layer Thickness | 15-25 microns (per side) | 15-25 microns (per side) |

| Coil Weight | 3-8 Metric Tons (typical) | 3-8 Metric Tons (typical) |

| Color Range | Wide variety available | Wide variety available |

| Corrosion Resistance | Good, due to zinc coating | Excellent, due to aluminum-zinc coating |

| Durability | High | Higher than PPGI |

| Application Areas | Construction, roofing, appliances, etc. | Construction, roofing, harsh environments |

| Special Features | UV resistance, easy formability | Superior corrosion resistance, longevity |

Highlighting their base materials, coatings, physical dimensions, and application areas. PPGI coils are known for their good corrosion resistance and are widely used in various applications, while PPGL coils offer superior corrosion resistance and durability, making them suitable for harsher environmental conditions. The specifications are typical values and can vary depending on the manufacturer and specific product lines.