Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

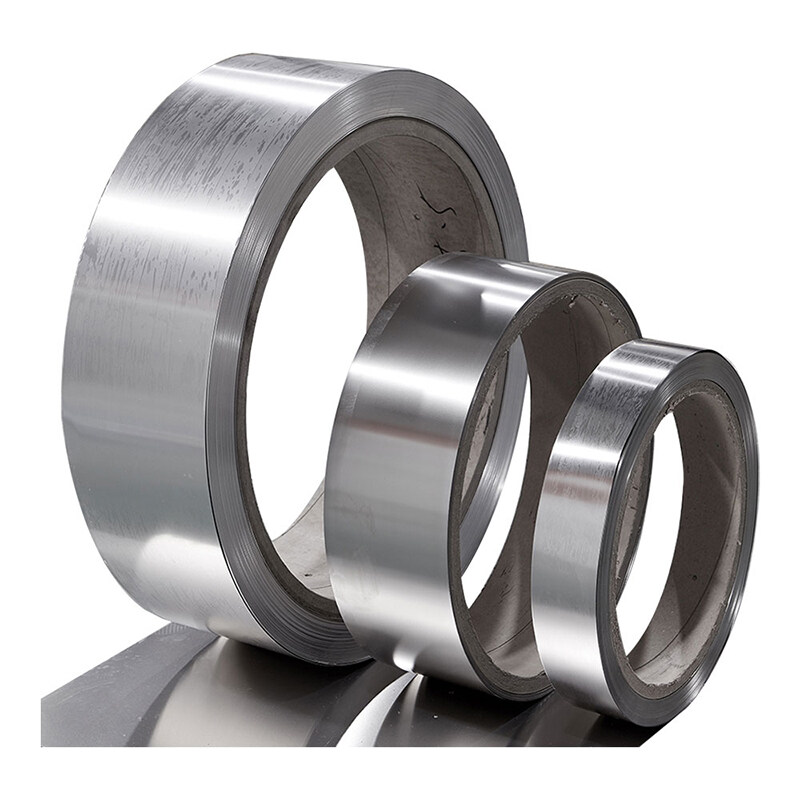

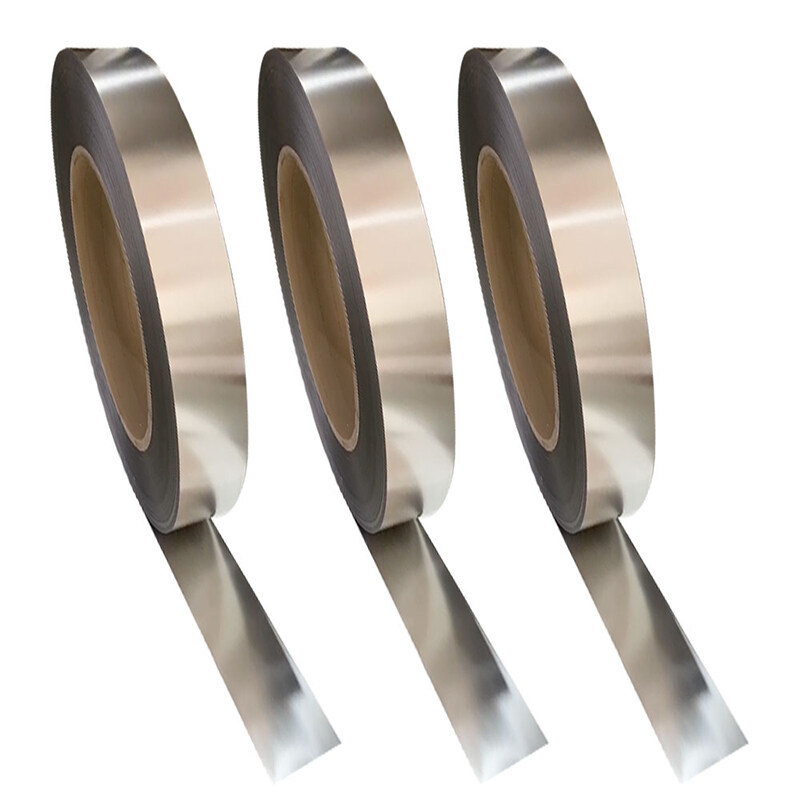

Mirro polished stainless steel strip thickness 1mm-2mm SS304 SS316

Our mirror-polished stainless steel strips are available in thicknesses ranging from 1mm to 2mm, and are made from high-quality 304 and 316 stainless steel. These materials are known for their excellent anti-corrosion properties and resistance to deformation, making them ideal for a wide range of applications. Additionally, they do not cause any damage or chemical reactions, allowing them to maintain their original appearance over time.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

The Mirror Polished Stainless Steel Strip Thickness 1mm-2mm SS304 SS316 are known for their excellent anti-corrosion properties and resistance to deformation, making them ideal for a wide range of applications. Moreover, they do not cause any damage or chemical reactions, allowing them to maintain their smooth and bright appearance over time.

Highly Reflective Surface:

The mirror polished stainless steel strip has a highly reflective surface that is smooth and free of imperfections. It is polished to a high degree, giving it a mirror-like finish that is both aesthetically pleasing and functional. This makes it ideal for a wide range of applications, including those in harsh environments where corrosion and staining are a concern.

Corrosion and Stain Resistance:

The mirror polished stainless steel strip is highly resistant to corrosion and staining, making it an excellent choice for use in harsh environments. Its durability and resistance to damage ensure that it can withstand exposure to moisture, chemicals, and other harsh conditions without deteriorating or losing its shine.

Excellent Mechanical Properties:

The mirror polished stainless steel strip has excellent mechanical properties, including good bending, fatigue resistance, and elastic blade performance.

Smooth Edge:

The mirror polished stainless steel strip features a smooth edge, which is crucial for certain applications. A smooth edge ensures that the strip can be easily and safely handled without causing injury or damage to other materials. It also provides a clean and polished look, making it ideal for decorative applications where aesthetics are important.

Scratch-resistant Surface:

The mirror polished stainless steel strip is highly scratch-resistant. Its smooth and polished surface is not easily marred by scratches or other surface damage, ensuring that it maintains its pristine appearance over time. This makes it ideal for use in applications, such as in architectural design, interior decoration, and furniture manufacturing.

Product Parameter:

|

Material |

201/304/304L/316/316L/430 Stainless Steel Sheet |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Surface |

2B / BA /NO.1/ NO.4/HL/8K/6K |

|

Standard |

AiSi |

|

Hardness |

150HV-570HV |

|

Surface Finish |

No.4 |

|

Length |

10-12000mm or Customized |

|

Thickness |

0.5mm - 1.0mm/ Customized |

|

Certification |

ISO 9001/ IATF16949 |

|

Width |

10mm-600mm or As Request |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Electronic Products, Automotive, Medical, etc |

In the process of metal surface treatment, stainless steel plane grinding and polishing requirements are the most common, and the requirements are also different. If you want to obtain high-quality polishing effects, the most important thing is to have good quality automatic surface grinding and polishing machines, polishing consumables and corresponding supporting polishing programs and skilled operators.

The most important requirement for the entire polishing quality is the polishing procedure. The polishing procedure depends on the processing of the workpiece in the early stage and the roughness of the blank before polishing. Such as machining, EDM, grinding, casting and so on.

What is stainless steel mirror polishing?

Common mirror stainless steels are divided into three types: 6K, 8K, and 10K. Generally, it is ordinary polishing, ordinary 6K, fine grinding 8K, and super fine grinding 10K effect. Generally, there is not much difference between the same thickness, and the 10K mirror surface is brighter; the thicker the thickness, the worse the effect and the higher the processing cost.

To achieve the mirror effect of stainless steel plane polishing, we generally divide it into three steps: rough polishing, semi-fine polishing, and fine polishing.

Rough polishing: Generally, automatic plane grinding and polishing machines use hard grinding discs, such as copper discs and iron discs. The main function is to make the flatness of the flat stainless steel products relatively consistent through the rotation of the grinding disc and the physical and chemical effects of the grinding disc and the grinding fluid.

Semi-fine polishing: Generally use relatively soft abrasive consumables and abrasive liquid with relatively fine particles for grinding to achieve fine and coarse polishing lines. This step is very important, because the size of the lines will affect the mirror effect of polishing.

Fine polishing: Fine polishing usually uses soft consumables and polishing liquid for polishing to achieve a mirror effect. Different effects require different consumables and processing time.

Common mirror polishing forms

According to the polishing method, there are three common forms of stainless steel mirror polishing: mechanical polishing, chemical polishing and electrochemical polishing;

At present, the commonly used mirror polishing equipment is mainly to rotate the stainless steel plate or other types of metal plate counterclockwise through the grinding disc with adjustable pressure, the correction wheel drives the workpiece to rotate, and the method of gravity pressure applies pressure to the workpiece. Grinding emulsion (mainly a combination of metal oxides, inorganic strong acids, organic lubricants and weak alkaline cleaning agents), the workpiece and the grinding disc are operated and rubbed against each other to achieve the purpose of grinding and polishing. The mirror polishing machine can be divided into three steps: grinding, polishing and grinding; the matching abrasives, grinding materials and grinding fluids are also different according to its different sections.

Stainless steel strips of various materials and thicknesses can be processed into different degrees of mirror effect; due to the macro unevenness of the base metal (the surface roughness Ra value is generally big, the surface roughness must be ground first by grinding to a certain value (Ra ≤ 0.8μm), and then grind to a "mirror surface" by grinding.