Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

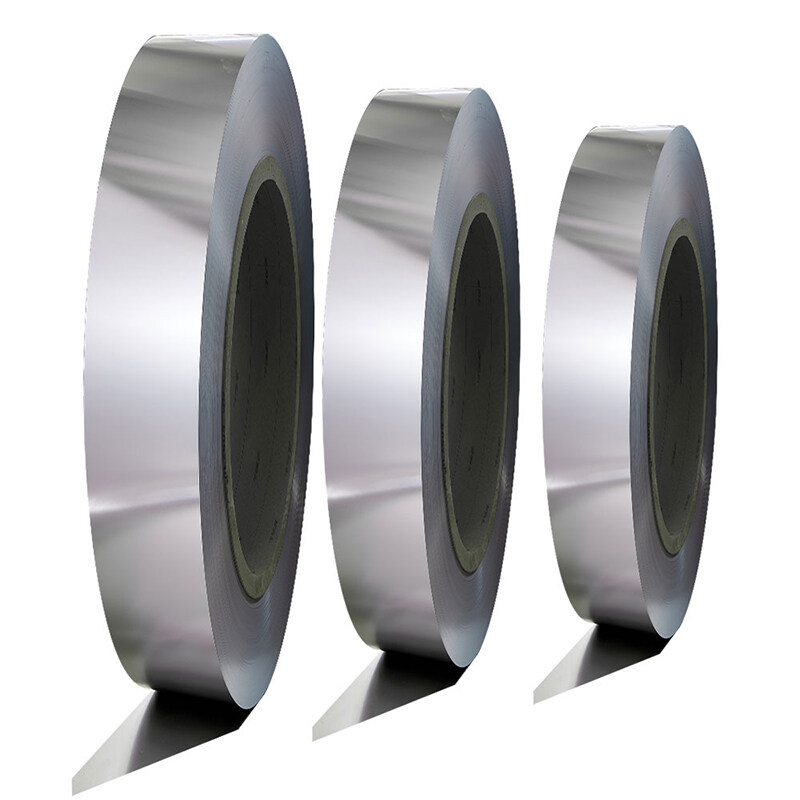

ss band cold rolling 201 410 Stainless Steel Strip

Our cold-rolled 201 410 stainless steel strips for sheet metal stamping are polished to ensure a smooth surface, making it convenient for use in various applications. The 201 and 410 stainless steel meet national standards and are highly resistant to acid and alkali liquids, providing you with peace of mind.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H,H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

This is our ss band cold rolling 201 301 316 316L 304 410 430 440C Stainless Steel Strip for Sheet metal stamping, any interests, welcome to contact us at any time!

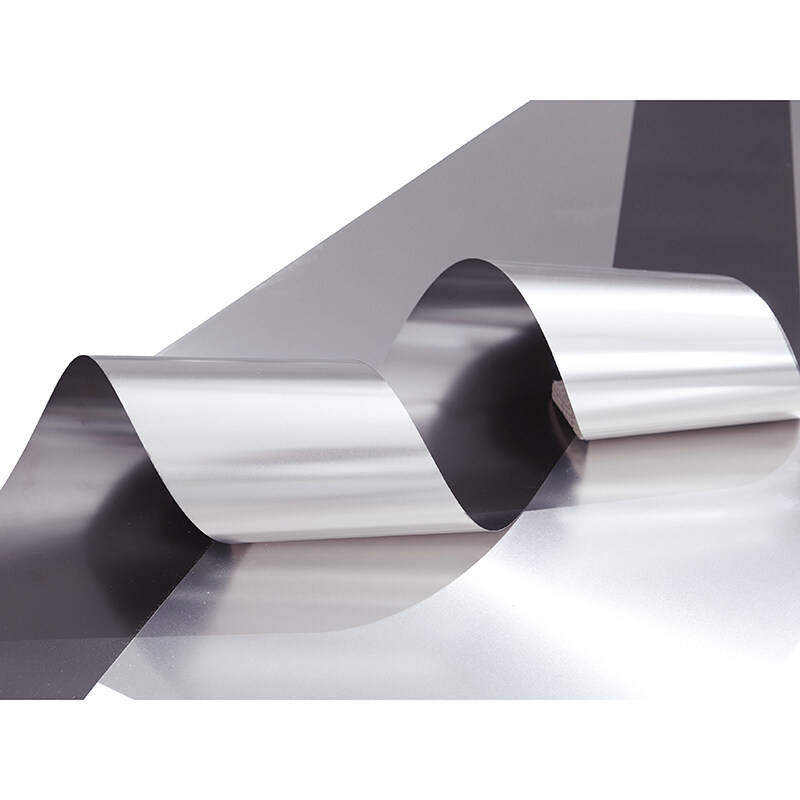

The stainless steel strip is a premium-grade material that has been meticulously crafted to meet the exacting demands of sheet metal stamping. Its exceptional ability to withstand high temperatures up to 650 ℃ makes it an ideal choice for use in high-temperature applications, where other materials may falter. Moreover, its superior corrosion resistance, particularly in harsh acid and alkali environments.

Superb Formability:

It boasts exceptional formability, allowing it to be easily shaped and bent to meet the most intricate design specifications. Its malleability and ductility make it a versatile material that can be formed into a wide range of shapes and sizes, without compromising its structural integrity or aesthetic appeal.

Good Strength:

It is renowned for its exceptional strength and ability to withstand heavy loads, making it an ideal choice for a wide range of industrial applications. Its high tensile strength and durability ensure that it can withstand even the most demanding environments, without compromising its structural integrity or performance.

Multifunctional for Sheet Metal Stamping:

Its multifunctional properties make it an ideal choice for a wide range of industrial applications for metal stamping, including automotive, aerospace, and construction parts. With its exceptional strength, durability, and corrosion resistance, it can withstand even the most demanding environments, ensuring long-lasting performance and reliability.

Good Machinability:

Its unique composition and properties make it easy to machine and fabricate, allowing for precise cuts and intricate designs. Whether you require a material that can be easily drilled, turned, or milled, the stainless steel strip can be expertly crafted to meet your exacting requirements.

Product Parameter:

|

Stainless Steel Hardness

|

||||||

|

|

2B

|

1/4H

|

1/2H

|

3/4H

|

H

|

EH

|

|

SUS 201

|

≤HV220

|

HV200-230

|

HV240-290

|

HV300-350

|

HV360-410

|

≥H420

|

|

SUS 304

|

≤HV190

|

HV190-250

|

HV250-310

|

HV310-370

|

HV370-430

|

≥H430

|

|

SUS 316

|

≤HV160

|

HV180-220

|

HV240-290

|

HV300-350

|

≥HV360

|

|

|

SUS 316L

|

≤HV190

|

HV190-250

|

HV250-310

|

HV310-370

|

HV370-430

|

≥H430

|

|

SUS 301

|

≤HV220

|

HV250-310

|

HV310-370

|

HV370-430

|

HV430-490

|

≥H490

|

|

SUS 430

|

≤HV160

|

HV170-210

|

HV210-250

|

HV250-290

|

≥HV290

|

|

|

Material

|

Stainless Steel |

|

Technique |

Hot Dipped / Cold Rolled |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Certification |

ISO 9001/ IATF16949 |

|

Standard |

JIS, AiSi, ASTM, GB, DIN, EN SKU |

|

Surface Finish |

2B |

|

Length |

Customized |

|

Thickness |

0.03mm-2.5mm or Customized |

|

Standard |

ASTM AISI JIS DIN GB |

|

Width |

10mm-600mm |

|

Hardness |

150HV-570HV |

|

Tolerance |

±1% |

|

Processing Service |

Welding, Punching, Cutting, Bending, Decoiling |

|

Application |

Metal Stamping |

Definition of stainless steel strip

Stainless steel strip can be understood as an extension of ultra-thin stainless steel plate, which is usually a long and narrow stainless steel plate manufactured to meet the needs of various industrial mechanical products.

Stainless steel strip is also known as stainless steel strip. Its maximum size and width shall not exceed 1220mm, but its length is not limited. According to the processing method, stainless steel strip can be divided into cold-rolled stainless steel strip and hot-rolled stainless steel strip.

Stainless steel strip has excellent strength, precision and surface finish, and is widely used in aerospace, petrochemical, automotive, textile, electronics, home appliances, computers, precision machining and other pillar industries.

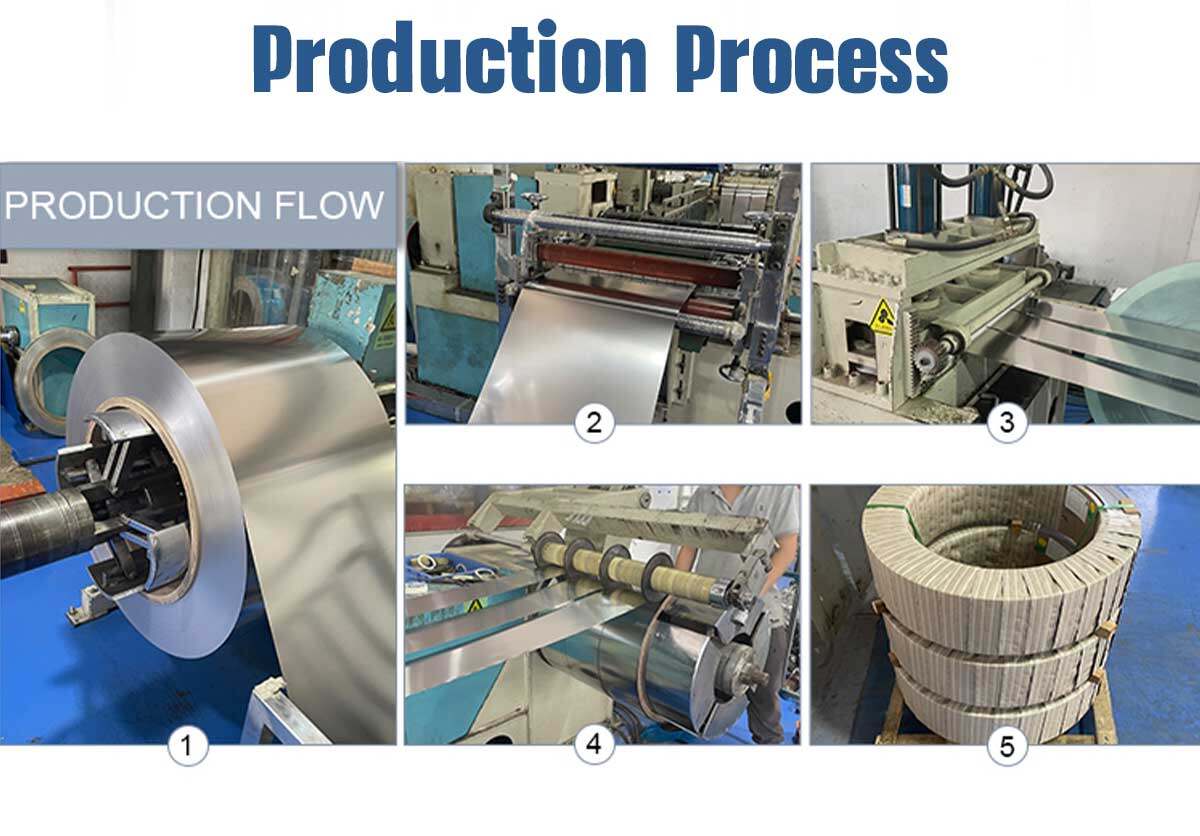

Cold rolled stainless steel strip

With stainless steel strip or stainless steel coil as raw material, it is rolled by cold rolling mill at room temperature. The conventional thickness is 0.1mm ~ 3mm, and the width is 100mm ~ 2000mm.

Cold rolled stainless steel strip has many advantages, such as smooth and flat surface, high dimensional accuracy, good mechanical properties and so on. It can be rolled or processed into coated steel plate. The sequence of its production process is acid pickling, normal temperature rolling, process lubrication, annealing, leveling, fine cutting and packaging.

Hot rolled stainless steel strip

Hot rolled stainless steel strip is produced by hot rolling mill with thickness of 1.80mm-6.00mm and width of 50mm-1200mm. Hot rolled stainless steel has many advantages, such as low hardness, easy processing, good ductility and so on. Its production process is acid pickling, high temperature rolling, process lubrication, annealing, leveling, fine cutting and packaging.

Differences between cold and hot rolled stainless steel strips

There are three main differences between cold-rolled stainless steel strip and hot-rolled stainless steel strip:

First of all, cold-rolled stainless steel strips have better strength and yield, and hot-rolled stainless steel strips have better ductility and toughness.

Secondly, the thickness of cold-rolled stainless steel strip is ultra-thin, and the thickness of hot-rolled stainless steel strip is a little thick.

In addition, the surface quality, appearance and dimensional accuracy of cold-rolled stainless steel strip are better than that of hot-rolled stainless steel strip.

What are the precautions for the production and processing of stainless steel strip?

1. Before starting, it is necessary to check whether the rotating parts and electrical parts of the equipment are safe and reliable. If there is any abnormality, it should be repaired by relevant personnel in time.

2. The stacking materials in the workplace should be neat, and there should be no obstacles on the passage.

3. Operators need to wear work clothes, tighten the cuffs, and wear work caps, gloves, and protective glasses.

4. When driving, it is strictly prohibited to clean, refuel and repair equipment, and it is not allowed to clean the workplace. When driving, it is forbidden to touch the steel belt and rotating parts with hands.

5. When driving, it is strictly forbidden to put tools or other objects on the equipment or protective cover.

6. When using the electric hoist, observe the safety operation procedures of the electric hoist, check whether the steel wire rope is complete and easy to use, and pay attention to whether the hook is hung well. When lifting the steel belt, it is not allowed to tilt or hang the steel belt during production.

7. When the work is finished or the power is cut off halfway, the power supply should be cut off immediately.

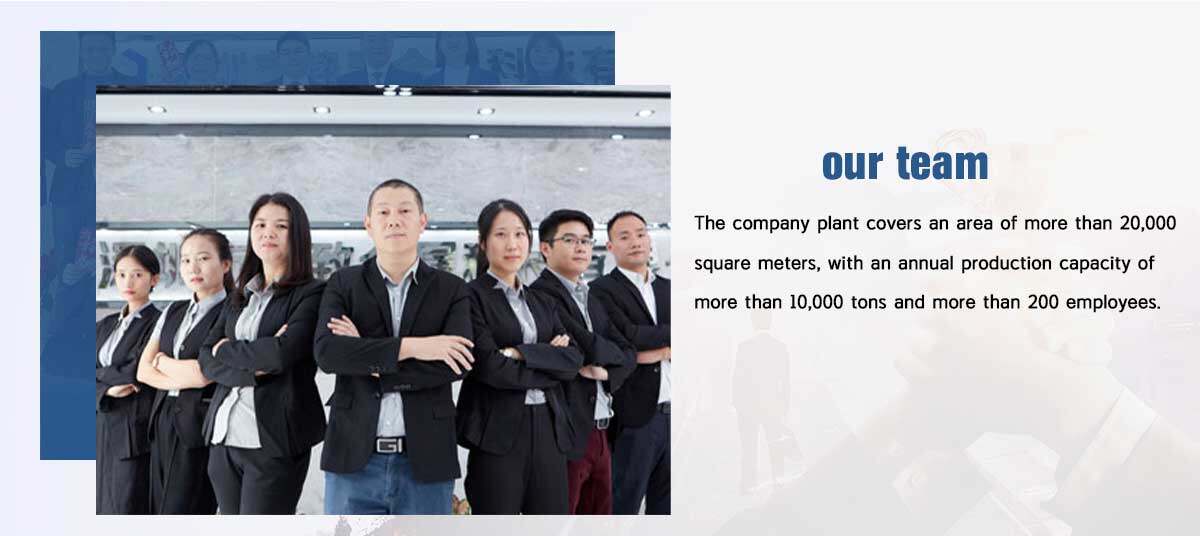

What we have

Floor space: more than 20,000 square meteres

Production capacity: annual production capacity of more than 10,000 tons

16 years experience: Focus on the precision metal alloy material industry for more than 16 years.

Our services

- Customers' Request

- Free Sample

- Special Surface Processing

- Second Treatment according to customer requirements, such as: surface, width, etc.

Logistics

Transportation: sea, land

Delivery time: 15-25 working days

Packing: plastic film inside, woven bag outsourced and transported in a custom wooden box.

FAQ?

Q: What is the MOQ?

A: MOQ: 500kg.

Q: What is your delivery time?

A: 7-25 working days.

Q: What is the payment method?

A: 30% deposit is paid in advance before production, and the balance is paid before shipment

Q: Can you guarantee the quality of the product?

A: Yes, we can.

Q: Are you a factory or a trading company?

A: Industry and trade integration

Q: Where is your factory?

A: Room 101, Building B, No. 3 Education North Road, Yixin Community, Pingdi Street, Longgang District, Shenzhen, welcome to visit.

Q: Are custom services available?

A: Yes, they are available.

Q: Do you support OEM and ODM?

A: Yes.

Q: Why choose us?

A: We have a number of slitting, shearing, electroplating, painting, wire drawing surface treatment production lines, which can meet the needs of different customers, rich market resources, sufficient inventory, complete specifications, and a complete technical team.

Q: Does your packaging ensure product safety?

A: Yes, we adopt quality package.

Q: What information do I need to provide to get an accurate quote?

A: Please provide us with these information: material, hardness, surface, width, thickness.

Q: How can I get product progress without going to your company?

A: We provide one-to-one customer service.

Q: How can I deal with this if I don't receive the item?

A: We will have special personnel responsible for following up the logistics of the goods.

Q: How is your after-sales service?

A: The company will have special personnel responsible for following up the logistics of the goods.

Q: Can samples be ordered?

A: Yes, they can.

Q: How much is the sample fee, can it be refunded after bulk product?

A: Samples are free, so all no fees are refunded.

Q: Do you provide quality assurance?

A: Yes.

Q: Do you support providing samples?

A: Free sample (without shipping).

Q: What is the monthly supply capacity?

A: 1000 tons/month.