Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

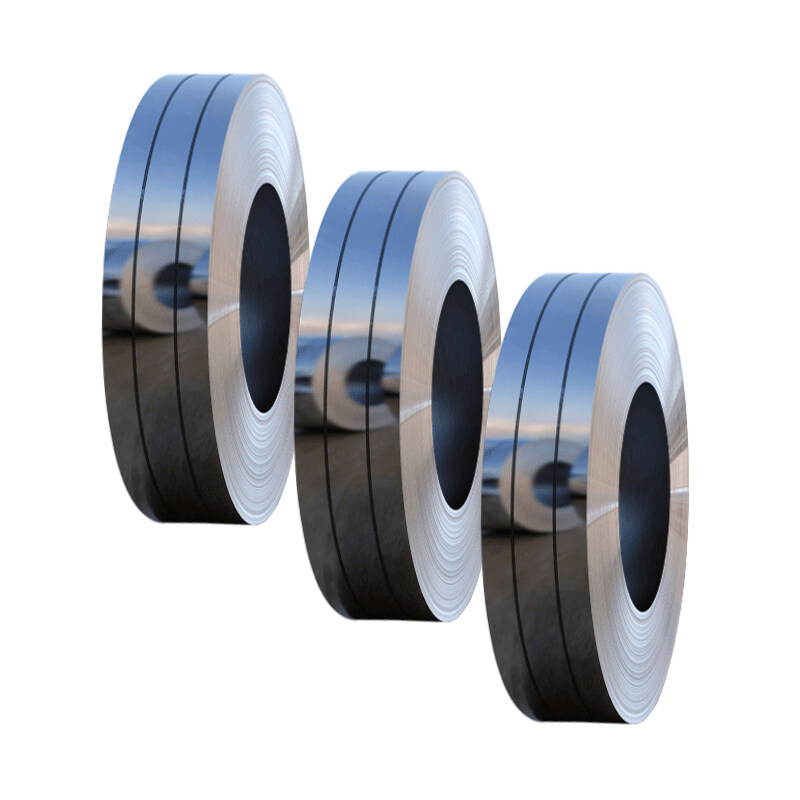

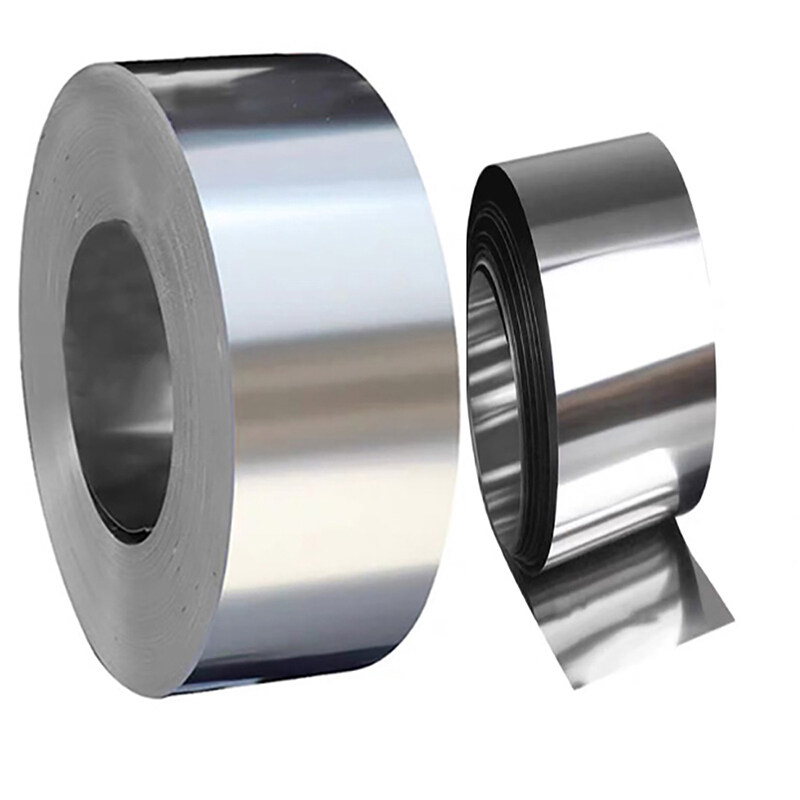

Sus cold rolled 2b finished band stainless steel strip 304 sheet

Stainless steel strip is constructed with durable 304 stainless steel, ensuring superior strength and longevity. The polished finish provides a smooth, corrosion-resistant surface that is easy to clean. This sheet is perfect for making parts, frames, and other components that require a high level of precision and quality. Its excellent performance in a range of temperatures makes it an ideal choice for any project.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

Stainless steel strip is constructed with durable 304 stainless steel, ensuring superior strength and longevity. The polished finish provides a smooth, corrosion-resistant surface that is easy to clean. This sheet is perfect for making parts, frames, and other components that require a high level of precision and quality.

Durability:

Stainless steel cold-rolled strip products are highly durable and can withstand harsh environments, extreme temperatures, and heavy usage. This makes them ideal for use in applications that require long-lasting and reliable materials.

Low Maintenance:

Stainless steel cold-rolled strip products require minimal maintenance, making them a cost-effective choice for many industries. They are resistant to corrosion, staining, and rust, which means they do not require frequent cleaning or replacement.

High Temperature Resistance:

Stainless steel cold-rolled strip products can withstand high temperatures without losing their strength or structural integrity. This makes them ideal for use in applications that require materials that can withstand extreme heat, such as in the aerospace and energy industries.

Design Flexibility:

Stainless steel cold-rolled strip products can be easily formed and shaped into various designs and sizes, making them a versatile material for many industries. They can be used to create complex shapes and structures, which makes them ideal for use in architectural and decorative applications.

Hygienic Properties:

Stainless steel cold-rolled strip products have excellent hygienic properties, making them ideal for use in the food processing and medical industries. They are easy to clean and sanitize, which helps to prevent the growth of bacteria and other harmful microorganisms.

Environmental Sustainability:

Stainless steel is a highly recyclable material, which means that it can be reused and repurposed without losing its quality or properties. This makes it an eco-friendly choice for many industries that are looking to reduce their environmental impact and promote sustainability.

Product Parameter:

|

Material |

Aluminum Alloy Metal |

|

Surface |

TSTS |

|

Steel Grade |

301L, 301, 316L, 316, 304, 304L, 301LN |

|

Color |

Natural color |

|

Surface Finish |

Miror Polishing |

|

Length |

Customized |

|

Thickness |

1mm |

|

Width |

250-1500mm |

|

Hardness |

58-66 |

|

Grade |

300Series |

|

Tolerance |

±0.25% |

|

Application |

Bearing Accessories Decoration |

Application:

1.Architectural decoration

2.Home appliances

3.Rail transportation

4.Automobiles

5.Elevators

6.Containers

7.Solar energy

8.Precision electronics

Characteristics of stainless steel cold-rolled strip products

Various types of surface processing

Stainless steel has become a widely used metal material for its excellent corrosion resistance, good mechanical properties and processing properties. Through different processing methods of cold rolling and surface reprocessing after cold rolling, the surface of stainless steel can have different grades of surface finish, texture and color. The surface processing of stainless steel cold-rolled sheet includes 2D, 2B, No.3, No.4, 240, 320, No.7, No.8, HL, BA, TR hard state, embossing and other surface grades.

On the basis of the cold-rolled surface, various deep-processed surfaces such as electroplating, electrolytic polishing, non-directional hairline, etching, shot peening, coloring, coating and combinations thereof can be further implemented. In addition to the No.1 surface after hot-rolling and pickling and the textured plate, there are more than 20 kinds of stainless steel surfaces.

Such a rich variety of surfaces greatly improves the appearance of stainless steel, making it aesthetically pleasing, increasing its appeal to consumers and giving people a beautiful enjoyment. The different surface processing of stainless steel broadens the connotation of the use of stainless steel, thereby expanding the scope of use of stainless steel.

Wide range of applications

Stainless steel cold-rolled strip products have become widely used metal materials due to their excellent corrosion resistance, good mechanical properties, processing properties and rich surfaces. They are widely used in architectural decoration, products, home appliances, rail transportation, Various civil and industrial fields such as automobiles, elevators, containers, solar energy, and precision electronics.

High surface quality requirements

As mentioned above, stainless steel cold-rolled strip products are widely used in various civil industries and industrial fields, among which most products in the building decoration, elevator, container and other industries directly use the 2D, 2B, BA, grinding and other surfaces after cold rolling products, household appliances, rail transportation, automobiles, solar energy, precision electronics and other industries will use cold-rolled surface products directly after forming or after shallow grinding and polishing. Therefore, the surface quality requirements for stainless steel cold-rolled strips are relatively high.

However, since the production of stainless steel cold-rolled strip needs to go through more than ten continuous production processes, it is inevitable to produce surfaces such as roll printing, pressing, scratches, dirt, scales, scales, scales, inclusions, and poor color. defect. The high requirements of customers for the use of stainless steel cold-rolled sheet and strip products are almost zero tolerance, which poses a high challenge to stainless steel cold-rolled sheet and strip producers.

The production of stainless steel cold-rolled strip needs to go through multiple processes such as steelmaking, hot rolling, and multiple continuous production links of the cold rolling process, and it is difficult to achieve zero defects. Therefore, the surface defects of the outgoing products are specified in the stainless steel cold-rolled strip standards of various countries.

But the steel strip usually has no chance of eliminating the defect, so it contains several abnormal parts. How to understand these three sentences in the standard description of visual inspection?

Firstly, the products that leave the factory may have defects, but these defects should not be harmful to the customer's use. Secondly, due to the continuity and particularity of cold rolling production, it is impossible to remove defective or even severely defective parts. It can also be said that it is very difficult to produce a roll of non-defective steel strips. Thirdly, some abnormal parts can be entrained in the factory steel strip.