Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

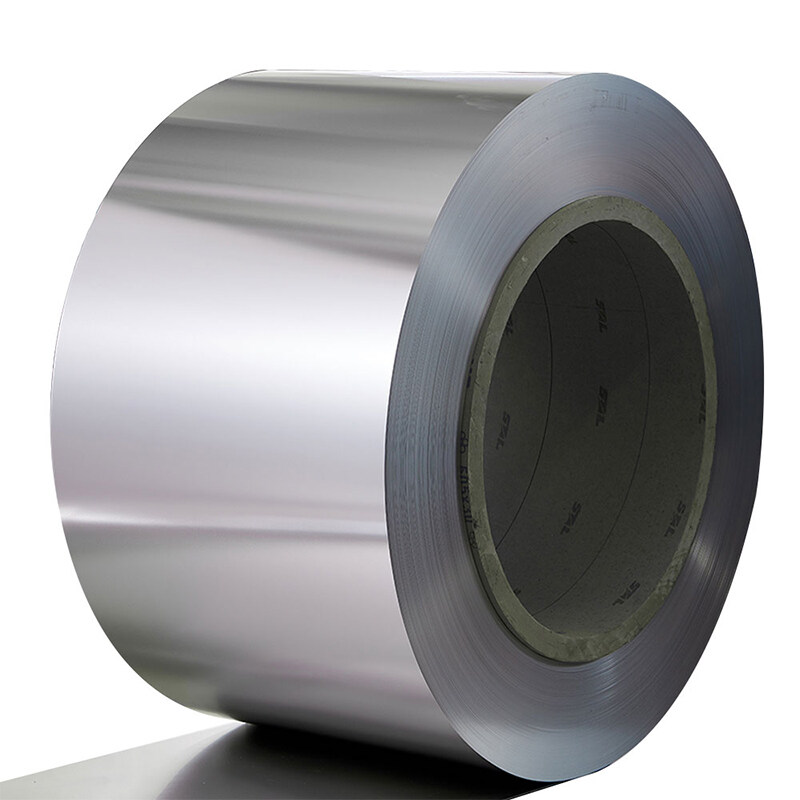

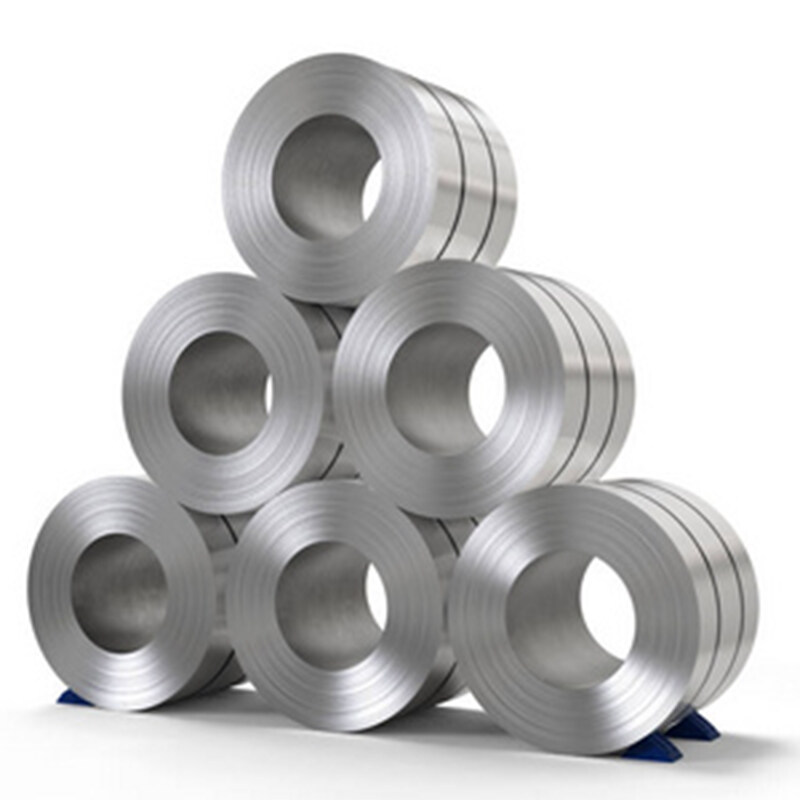

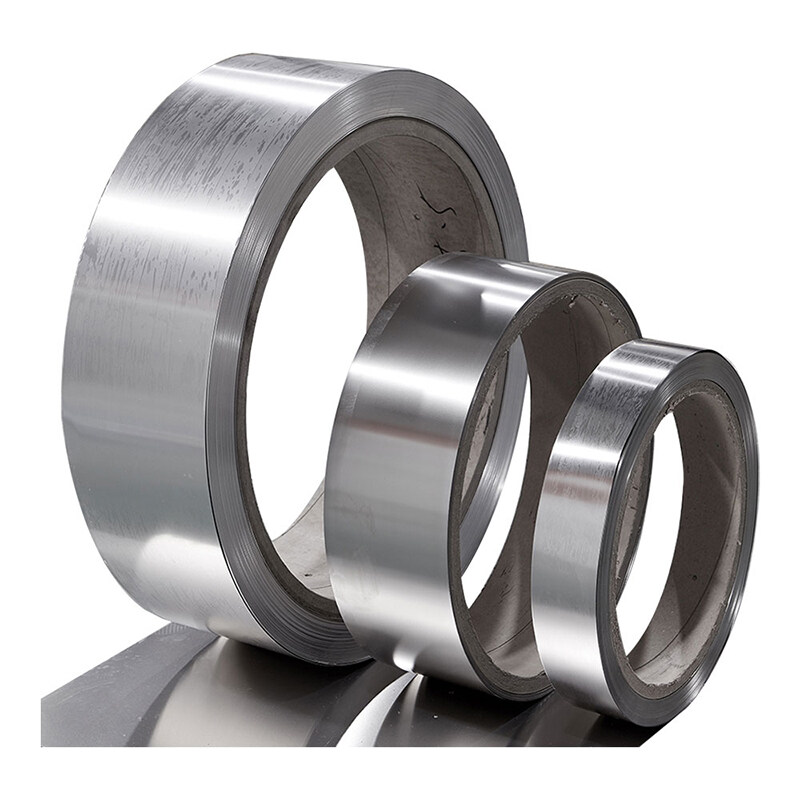

301 316 stainless steel coil

Looking for high-quality stainless steel coils at an affordable price? Look no further than our 301 and 316 stainless steel coils! We take pride in our careful packaging to ensure your coils arrive in perfect condition, free from any damage during transportation. As an experienced factory, we understand the importance of providing professional coils that are suitable for use in a variety of applications, ensuring their longevity and optimal performance. Trust us to provide you with a worthwhile purchasing experience that meets all your stainless steel coil needs.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

Welcome to find high quality best price 301 304 304L 316 316L stainless steel coil here.

Looking for high-quality stainless steel coils at an affordable price? Look no further than our 301 and 316 stainless steel coils! We take pride in our careful packaging to ensure your coils arrive in perfect condition, free from any damage during transportation. Trust us to provide you with a worthwhile purchasing experience that meets all your stainless steel coil needs.

Low Carbon Content:

The low carbon content in 316 stainless steel coil is a big deal because it helps prevent two types of corrosion: sensitization and intergranular corrosion.

Sensitization Corrosion

Sensitization happens when stainless steel is exposed to high temperatures, which can weaken it. But the low carbon content in 316 stainless steel coil helps prevent this from happening.

Intergranular Corrosion

Intergranular corrosion is another type of corrosion that can happen when stainless steel is exposed to certain environments, but the low carbon content in 316 stainless steel coil helps prevent this too. So basically, the low carbon content in 316 stainless steel coil makes it stronger and more resistant to corrosion.

Pitting & Crevice Corrosion:

316 stainless steel coil is great for use in environments with a lot of chloride because it’s resistant to two types of corrosion: pitting and crevice corrosion. These types of corrosion can happen when stainless steel is exposed to chloride-rich environments, but 316 stainless steel coil is tough enough to resist them. So if you need a material that can handle chloride-rich environments, 316 stainless steel coil is a good choice.

Product Parameter:

|

Material |

304 / 316 Stainless Steel |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Grade |

Galvanized |

|

Standard |

GB |

|

Surface Finish |

BA |

|

Length |

Customized |

|

Thickness |

0.1-3mm |

|

Certification |

API, RoHS, JIS, GS, ISO9001 |

|

Width |

As Request |

|

Tolerance |

±3% |

|

Processing Service |

Welding, Punching, Cutting, Bending, Decoiling |

|

Application |

Vehicle, Mobile Phone Accessories |

316 Stainless Steel Application:

316 stainless steel coil is used in a wide range of applications due to its excellent corrosion resistance and high strength.

It is commonly used in the manufacturing of chemical processing equipment, medical devices, marine equipment, and food processing equipment.

It is also used in the construction industry for structural components, such as bridges and buildings, and in the automotive industry for exhaust systems and other components that require high resistance to corrosion.

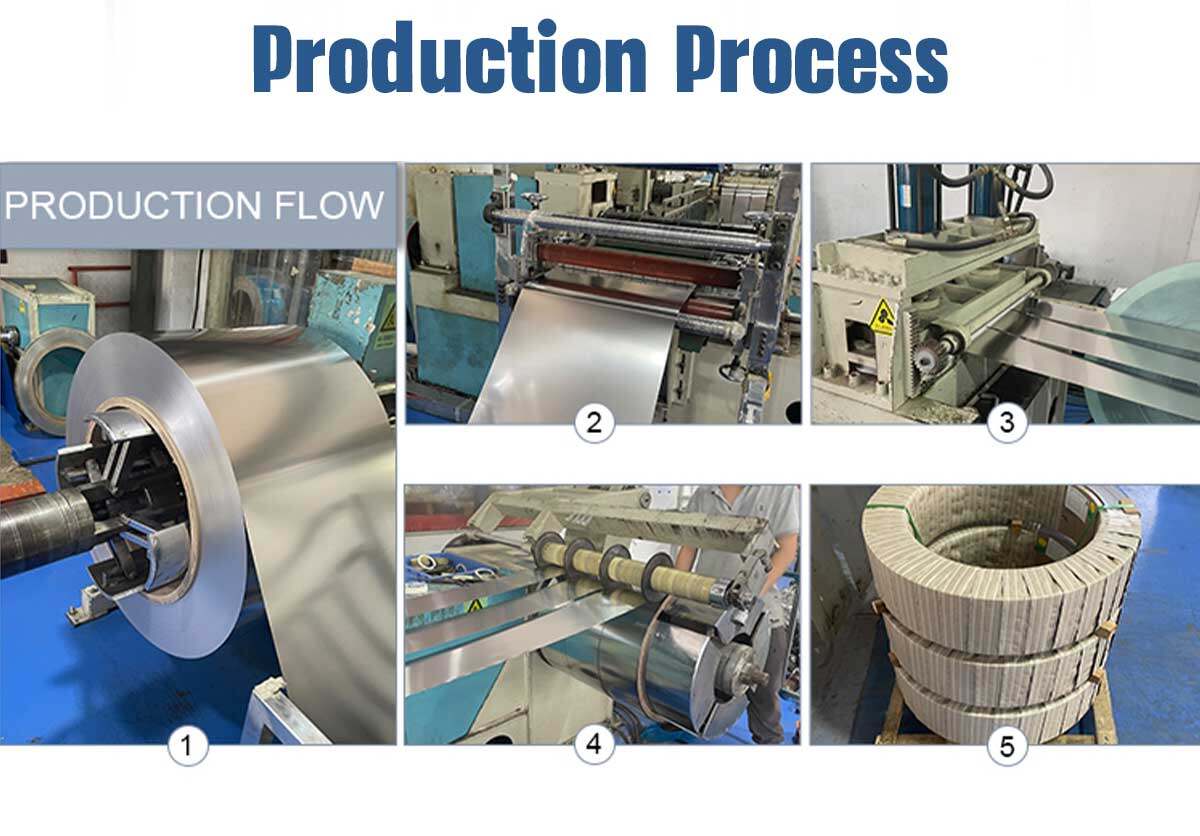

Purpose of stainless steel coil packaging

It is clear that the first is to protect products, the second is to facilitate transportation, and the third is to be beautiful. For the protection of stainless steel, there are many things to pay attention to.

There are three main parts of the Striped roll that should be protected during packaging: the first is the inner cylinder, the second is the side, and the third is the surface. For the inner drum, some slitting machines can put the cut paper drum (of the original coil) on the winder for winding, which has a great protective effect on those thin steel coils. For the side, it should be the most noteworthy. If the side is scratched carelessly, at least many layers are damaged. The scratch on the side reflects that there is a depression on the edge of each layer on the single layer. If it is welded pipe, it will cause perforation. The cause of side scratches is generally caused by friction with hard objects, such as mutual friction between slitting rolls, friction with hooks during lifting, etc. Therefore, in order to protect the side well, rubber or wood strips should be placed between rolls. Since the width of the slitting roll is fixed, the paper is generally not padded, but it can also be padded if there is a paper separator. For external surface protection, you can generally use wrapping paper. If you can use the plastic skin used in the original roll, it is also good.

For the Striped roll, there is also a kind of winding packaging, which must be packed by a special winding packaging machine. This kind of winding packaging can effectively protect the inner cylinder, side and outer surface, and can also be waterproof. Customers with high requirements for striped stainless steel coils can use this packaging method.

Remind

If there are some higher requirements, the whole striped roll can also be packed with plastic film, which can completely prevent water and dust, and has a beautiful appearance. The biggest difference between striped packaging and flat packaging is that there are many customized ones. If you want to fully meet the needs of customers, you must be able to customize all kinds of wooden frames, as well as mechanical appliances such as tipping machine, winding packer, paper separator, etc. Although the investment is relatively large, it is still worthwhile to provide the packaging required by customers and improve the product image.

Cleaning method of stainless steel coil

The stainless steel coil determines the effect of rainwater scouring by placing the same strip directly in the atmosphere and in a covered place. The effect of manual washing is determined by manually rubbing the right side of each strip with a sponge and soapy water every six months. The results showed that the removal of dust and siltation on the surface by rain washing and manual scrubbing had a good effect on the surface condition compared with the lath placed in a shed and not washed. It is also found that the condition of surface processing also has an impact. The effect of lath with smooth surface is better than that with rough surface.

Therefore, the washing interval is affected by many factors, and the main influencing factor is the required aesthetic standard. Although many stainless steel curtain walls are washed only when cleaning the glass, generally speaking, the stainless steel used for the outside is washed twice a year.

Our services

- Customers' Request

- Free Sample

- Special Surface Processing

- Second Treatment according to customer requirements, such as: surface, width, etc.

?Logistics?

Transportation: sea, land

Delivery time: 15-25 working days

Packing: plastic film inside, woven bag outsourced and transported in a custom wooden box.

?FAQ?♂️

Q: What is the MOQ?

A: MOQ: 500kg.

Q: What is your delivery time?

A: 7-25 working days.

Q: What is the payment method?

A: 30% deposit is paid in advance before production, and the balance is paid before shipment

Q: Can you guarantee the quality of the product?

A: Yes, we can.

Q: Are you a factory or a trading company?

A: Industry and trade integration

Q: Where is your factory?

A: Room 101, Building B, No. 3 Education North Road, Yixin Community, Pingdi Street, Longgang District, Shenzhen, welcome to visit.

Q: Are custom services available?

A: Yes, they are available.

Q: Do you support OEM and ODM?

A: Yes.

Q: Why choose us?

A: We have a number of slitting, shearing, electroplating, painting, wire drawing surface treatment production lines, which can meet the needs of different customers, rich market resources, sufficient inventory, complete specifications, and a complete technical team.

Q: Does your packaging ensure product safety?

A: Yes, we adopt quality package.

Q: What information do I need to provide to get an accurate quote?

A: Please provide us with these information: material, hardness, surface, width, thickness.

Q: How can I get product progress without going to your company?

A: We provide one-to-one customer service.

Q: How can I deal with this if I don't receive the item?

A: We will have special personnel responsible for following up the logistics of the goods.

Q: How is your after-sales service?

A: The company will have special personnel responsible for following up the logistics of the goods.

Q: Can samples be ordered?

A: Yes, they can.

Q: How much is the sample fee, can it be refunded after bulk product?

A: Samples are free, so all no fees are refunded.

Q: Do you provide quality assurance?

A: Yes.

Q: Do you support providing samples?

A: Free sample (without shipping).

Q: What is the monthly supply capacity?

A: 1000 tons/month.