Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

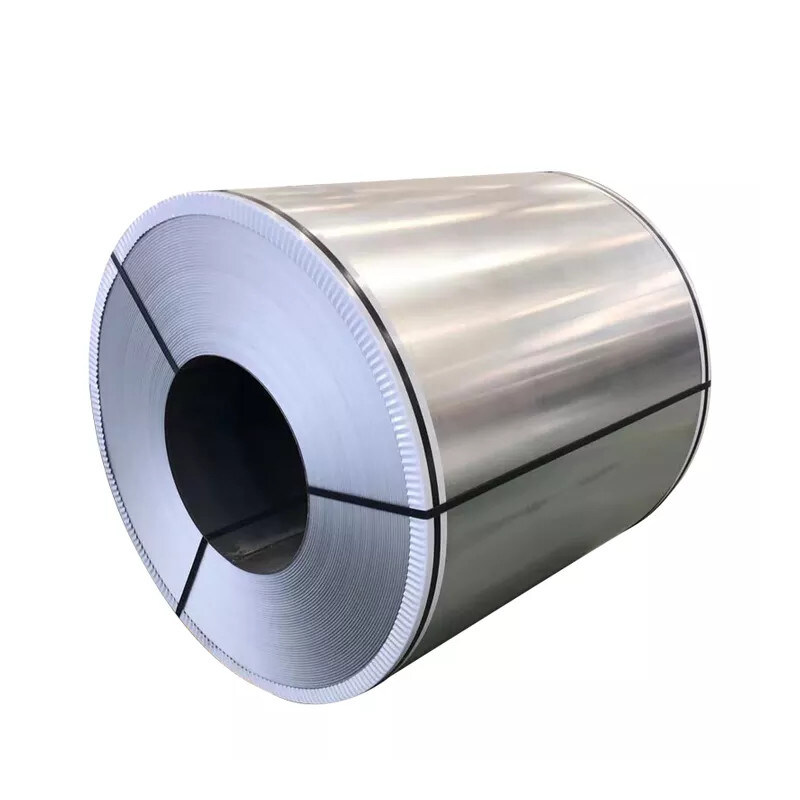

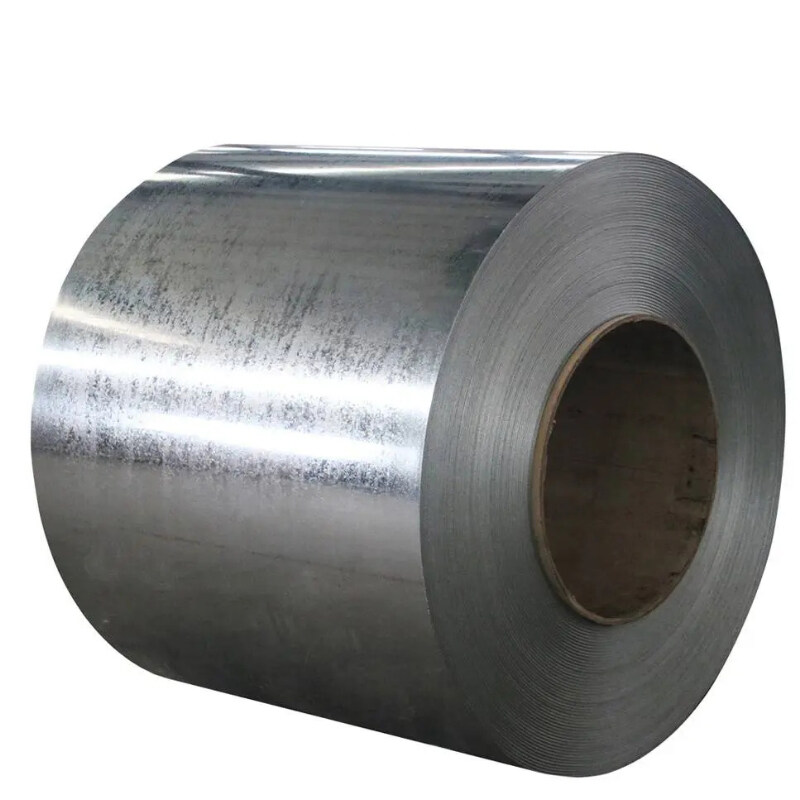

Sgcc Spcc Hot Dipped Cold Roll Iron Sheet Dx51d HDGI galvanized steel coil

This hot-dipped cold-rolled iron sheet is made from high-grade HDGI galvanized steel coil and is designed to provide superior strength and durability. The sheet is perfect for a variety of projects, from roofing and siding to framing and other construction needs.

You can find quality SGCC SPCC Hot Dipped Cold Roll Iron Sheet Dx51d HDGI galvanized steel coil ceiling tile here, we are a professional manufacturer of SGCC SPCC material. Any interests, welcome to contact us.

The HDGI Galvanized Steel Coil is a highly durable material that boasts strong anti-oxidation properties. This makes it an excellent choice for a wide range of projects, from roofing and siding to framing and other construction needs. Its anti-corrosion penetration ability helps to strengthen the longevity of parts, ensuring that they remain in excellent condition for years to come.

Good Protection for Rust and Corrosion:

The SGCC SPCC Hot Dipped Cold Roll Iron Sheet is a highly effective material that provides excellent rust and corrosion protection for steel. Hot dip galvanizing is a superior process that provides a longer life cycle for steel products, making it a cost-effective choice for a wide range of applications. Its superior corrosion resistance ensures that your products remain in excellent condition for years to come, even in harsh environments.

Longevity and Durability:

The maintenance schedule for hot-dip galvanized steel is directly related to the thickness of the coating. With proper coating thickness, the steel can go through various processing states and remain maintenance-free for several years.

Sharp and Smooth Surface:

The surface of this material is sharp and smooth, making it ideal for a wide range of applications, including decorative and container items. Its smooth surface eliminates the need for separate treatment or polishing, which can save you a significant amount of time and money. This makes it a cost-effective choice for a variety of projects, from large-scale construction to smaller DIY projects.

Product Parameter:

|

Material |

ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z/Q195-Q345 |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

AiSi |

|

Surface Finish |

2B |

|

Coating |

Z61-Z80 |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Grade |

300 Series |

|

Length |

100-10000mm or Customized |

|

Thickness |

2.1-3.0mm, 0.1mm-3mm or Customized |

|

Certification |

RoHS, ISO9001 |

|

Width |

Customized |

|

Tolerance |

±1%, ±5% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Making Pipes, Cutting Sheets, Making Small Tools, Making Corrugated Sheets, Making Container, Making Fences |

Application:

·Construction: such as roofing, siding, and framing.

·Automotive: such as body panels, chassis components, and exhaust systems.

·Industrial: such as manufacturing, machinery, and equipment industrial.

·Household Appliances: such as refrigerators, washing machines, and dryers.

You can find quality SGCC SPCC Hot Dipped Cold Roll Iron Sheet Dx51d HDGI galvanized steel coil ceiling tile here, we are a professional manufacturer of SGCC SPCC material. Any interests, welcome to contact us.

SPCC

S-STEEL P-plate c-cold rolled C-General commercial cold rolled steel sheet and strip for SPCC

SGCC

S-STEEL steel g-galvanized c-cold cold rolled fourth c-common ordinary grade means hot-dip galvanized steel sheet

DX51D

D-flat steel for cold forming, x-rolling state of unspecified substrate.

51~57: numbers represent the serial number of steel grade; D after two digits is the code of hot galvanizing. Z refers to pure zinc coating, ZF refers to galvanized iron alloy, and AZ refers to galvanized zinc coating.

Dx51d is a European standard. It is galvanized with 51 steel coils, which is equivalent to SGCC. Dx51d refers to the bending forming grade galvanized steel coil, with the steel number of 51 and low carbon steel as the base material.

About dx51 material

Dx51d galvanized sheet is made of non-ferrous alloy with zinc as matrix and other elements added. The main alloy elements are aluminum, copper, magnesium, etc. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and atmospheric corrosion resistance.

According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The commonly used casting zinc alloy is zinc aluminum copper magnesium alloy, which has good casting process performance, and the cooling rate has little effect on the mechanical properties. They are mainly used to make machine parts, toys, decorations and household appliances.

The commonly used forged zinc alloys are zinc aluminum alloy and zinc copper alloy.

The former contains 4% to 15% aluminum. In order to improve the strength and hardness of the alloy, a small amount of copper, magnesium and other alloy elements were added. High strength, easy to form, can replace part of brass or hard aluminum to make precision forgings.

The latter contains 0.7% to 1.5% copper. Copper can improve the strength and impact toughness of the alloy and reduce the plasticity. Zinc copper alloy is suitable for making daily hardware products or replacing some brass.

In addition, there are zinc titanium based and zinc lead cadmium iron-based deformed zinc alloys. The supply status of forged zinc alloy is wire rod, plate, forging or extrusion, etc.

What is hot dip galvanizing?

Hot dip galvanizing is a method of galvanizing steel and iron by coating with zinc. The steel enters a hot bath of molten zinc at about 842 degrees Fahrenheit. During this process, zinc will react with oxygen after being exposed to air.

It leads to the formation of zinc carbonate, which provides rust and corrosion protection for steel. Hot dip galvanizing provides a superior life cycle and is cost-effective due to its corrosion resistance.

The key features of HDG products are longevity and durability. The first maintenance time of hot-dip galvanized steel is proportional to / kloc-3 / coating thickness. It goes through different processing states and will not need maintenance in the next few years.

Hot dipped galvanizing and galvanizing

The difference between galvanized steel and hot-dip galvanized steel lies in texture and finish.

Galvanized materials have sharp and smooth surfaces, while hot-dip galvanized materials have rough textures. Zinc plating goes through different stages, forming a layer of zinc carbonate on the metal surface to protect it from corrosion.

Hot dip galvanizing is the process of forming a layer of pure zinc on the surface. It goes through three stages: preparation, galvanization and inspection.

For ease of understanding, galvanized materials have sharp and smooth textures, while hot-dip galvanized materials have rough surfaces. If considering performance and service life, hot-dip galvanized materials are cheaper than galvanized materials.

Hot dip galvanized materials are mistaken for being more expensive. Hot dip galvanizing is considered expensive because it has experienced a high-performance coating process.

If you consider its life span of 50 to 70 years, hot-dip galvanizing is a cheaper form of galvanizing.