Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

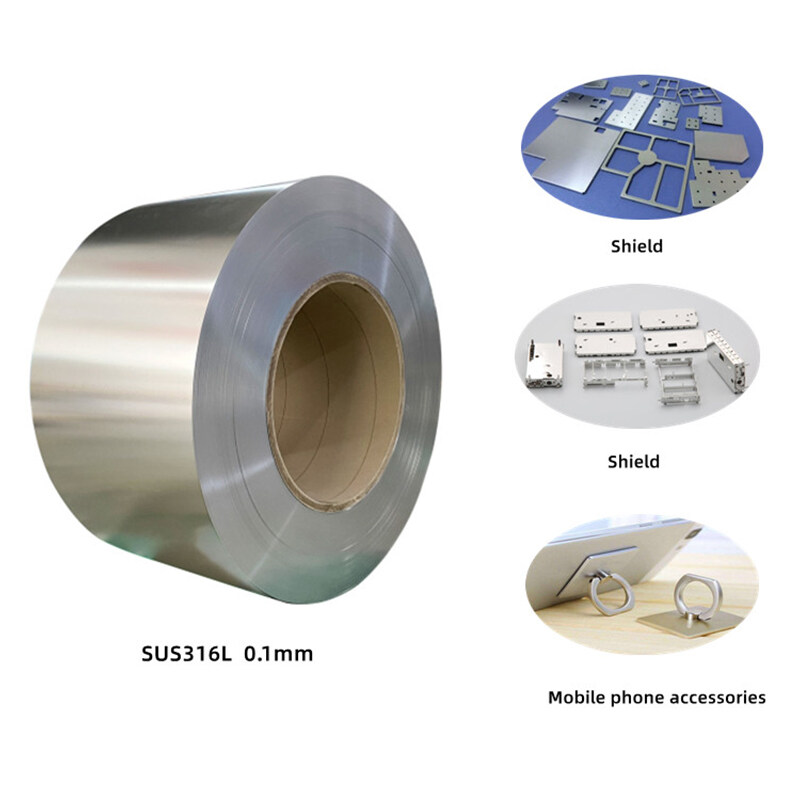

ODM cold rolled 316 stainless steel coil

In the realm of stainless steel, the 316 grade stands out for its enhanced corrosion resistance and strength, particularly in more aggressive environments. When processed through cold rolling, 316 stainless steel coils achieve a refined structure and surface finish, making them a premium choice in various demanding applications.

Understanding 316 Stainless Steel

316 stainless steel is known for its increased nickel content and the addition of molybdenum, which significantly improves its resistance to chlorides and acidic substances. It's an ideal material choice for applications where exposure to harsh chemicals or saline environments is a common occurrence.

Characteristics of Cold Rolled 316 Stainless Steel Coils

The cold rolling process enhances several key attributes of 316 stainless steel:

Enhanced Strength and Durability

Cold rolling increases the yield strength and hardness of the steel, making the coils more durable and resistant to wear and tear.

Superior Surface Finish

This process results in a smoother, cleaner surface, which is essential for aesthetic purposes and where surface integrity is critical.

Improved Dimensional Tolerance

Cold rolling allows for tighter dimensional tolerances, ensuring consistency and precision in the final product.

Versatile Applications

Cold rolled 316 stainless steel coils are widely used in:

- Marine Environments: For equipment and structures exposed to seawater.

- Chemical Processing: In equipment and storage tanks that handle corrosive substances.

- Medical Instruments: Due to its excellent cleanliness and non-reactivity.

- Food Processing: For machinery and surfaces where hygiene and corrosion resistance are paramount.

Advantages over Other Forms

Compared to hot rolled steel, cold rolled 316 stainless steel coils offer:

- Improved Mechanical Properties: Higher strength and better surface finishes.

- Enhanced Corrosion Resistance: Ideal for use in environments where corrosion is a major concern.

- Aesthetic Appeal: The smooth finish is suitable for visible architectural or consumer applications.

Sustainability Aspect

316 stainless steel is fully recyclable, aligning with global efforts towards sustainable materials and practices in manufacturing.

ODM cold rolled 316 stainless steel coil

Offering ODM (Original Design Manufacturing) services for cold-rolled 316 stainless steel coils involves a sophisticated process of producing customized stainless steel solutions tailored to specific client requirements.

-

316 Stainless Steel Characteristics: The 316 grade stainless steel is known for its enhanced corrosion resistance, particularly against chlorides and other industrial solvents, compared to 304 stainless steel. This makes it ideal for more demanding environments, such as marine or chemical processing applications.

-

Cold Rolling Process: The cold rolling technique used in manufacturing these coils involves processing the steel at or near room temperature. This process increases the strength of the steel through strain hardening and improves the surface finish. It also allows for tighter tolerances on thickness.

-

Customization in ODM: Our ODM services allow for extensive customization of the 316 stainless steel coils. Clients can specify the coil's thickness, width, and length as per their requirements. Additionally, we can tailor the mechanical properties, such as tensile strength and yield strength, to suit specific applications.

-

Surface Finishes: We offer various surface finishes, including 2B (a smooth, moderately reflective finish), #4 (a brushed finish), and BA (bright annealed), among others. These finishes provide not only the desired aesthetic qualities but also additional surface protection.

-

Applications: The customized 316 stainless steel coils are suitable for a wide range of applications, especially where high corrosion resistance is crucial. This includes marine environments, chemical processing equipment, pharmaceuticals, medical devices, and food processing equipment.

-

Quality Control: Our manufacturing process adheres to strict quality standards. We conduct thorough testing and inspections to ensure that our cold-rolled 316 stainless steel coils meet all required specifications, including chemical composition and physical properties.

-

Advanced Manufacturing Technology: We utilize state-of-the-art manufacturing technology to ensure precision and consistency in our cold-rolled coils. This includes advanced rolling mills and annealing processes to achieve the desired mechanical and physical properties.

-

Environmental Commitment: We are committed to sustainable manufacturing practices, striving to minimize our environmental impact through efficient use of resources, waste reduction, and recycling initiatives.

-

Collaborative Approach: Our ODM services are highly collaborative. We work closely with clients to understand their specific needs and provide tailored solutions, offering technical advice and support throughout the development process.

-

Global Supply and Logistics: We manage an efficient supply chain capable of delivering our customized 316 stainless steel coils to clients worldwide, ensuring timely and reliable delivery.

In summary, our ODM services for cold-rolled 316 stainless steel coils stand out for their customization capabilities, adherence to quality standards, and commitment to fulfilling the specific needs of diverse industrial applications in a sustainable and efficient manner.