Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

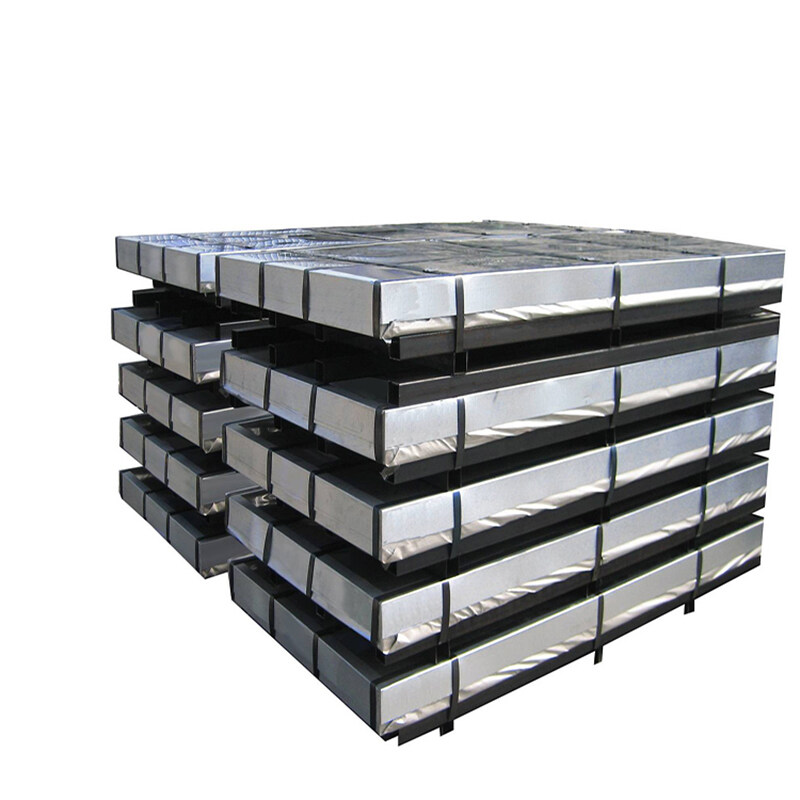

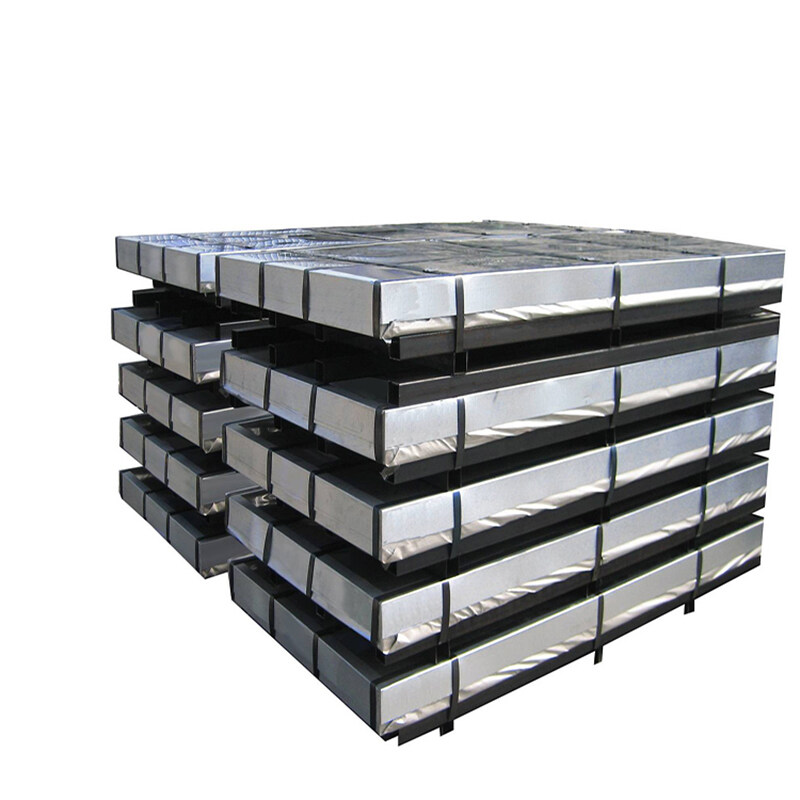

China's Premier 316 Stainless Steel Strip: Innovation Unveiled

Introduction

In the dynamic landscape of stainless steel, the 316 stainless steel strip stands out as a versatile and indispensable material. Manufactured with precision and expertise, this steel strip plays a pivotal role across various industries. This article delves into the fundamental aspects of 316 stainless steel strip, offering insights into its composition, manufacturing processes, applications, and the significant role played by the China 316 stainless steel strip factory in shaping the industry.

I. Understanding 316 Stainless Steel Strip

316 stainless steel strip, commonly known as 316 stainless steel strip, emerges as a stalwart in the realm of metallurgy. Its alloy composition, dominated by chromium, nickel, and molybdenum, confers exceptional corrosion resistance and mechanical strength. This high-performance steel strip finds applications across diverse sectors, from aerospace and marine engineering to pharmaceuticals and food processing.

II. The Manufacturing Craftsmanship

A. Raw Materials in Harmony

The China 316 stainless steel strip factory sources raw materials meticulously, ensuring the highest quality alloys. The synergy of chromium and nickel enhances the steel's corrosion resistance, while molybdenum fortifies it against chloride-induced corrosion. This meticulous selection is paramount for producing strips with enduring strength and longevity.

B. Precision in Processing Techniques

The manufacturing processes employed in the China 316 stainless steel strip factory are characterized by precision and innovation. Advanced technologies, such as cold rolling and annealing, impart the desired thickness, hardness, and surface finish to the strips. The result is a product of superior quality that meets the stringent requirements of various industries.

C. Commitment to Quality Control

The emphasis on quality control is a hallmark of the China 316 stainless steel strip factory. Rigorous testing protocols ensure that each strip adheres to international standards. This commitment to quality not only enhances the factory's reputation but also bolsters the global standing of 316 stainless steel as a reliable and durable material.

III. Key Features and Applications

A. Strength Redefined

The tensile strength and durability of 316 stainless steel strip make it an ideal choice for demanding applications. From structural components in construction to critical components in medical devices, its robust nature ensures reliability under diverse conditions.

B. Applications Across Industries

In the construction industry, 316 stainless steel strips find applications in structural elements exposed to harsh environments. In the medical field, its biocompatibility and corrosion resistance make it a preferred material for surgical instruments and implants. The China 316 stainless steel strip factory plays a pivotal role in meeting the escalating demand across these diverse industries.

IV. China 316 Stainless Steel Strip Factory: A Glimpse into Excellence

A. Cutting-Edge Facilities

The China 316 stainless steel strip factory stands as a beacon of technological prowess. Equipped with cutting-edge facilities and staffed by skilled professionals, the factory consistently delivers strips that exceed industry standards. This commitment to excellence positions China as a global leader in stainless steel manufacturing.

B. Technological Advancements

The integration of artificial intelligence and automation in the manufacturing processes of the China 316 stainless steel strip factory underscores a commitment to staying at the forefront of technological advancements. This not only enhances production efficiency but also reduces environmental impact, aligning with global sustainability goals.

C. Global Impact and Collaboration

The influence of the China 316 stainless steel strip factory extends far beyond its borders. Collaborations with international partners foster knowledge exchange and innovation. This global perspective ensures that the factory remains adaptive to evolving industry trends and standards.

V. Market Dynamics and Future Trends

A. Current Market Landscape

The demand for 316 stainless steel strips, especially those from the China factory, continues to rise. Industries worldwide recognize the unrivaled quality and durability offered by these strips, contributing to sustained market growth.

B. Environmental Considerations

In an era where environmental consciousness is paramount, the China 316 stainless steel strip factory actively engages in sustainable practices. Recycling initiatives and energy-efficient processes underscore the commitment to environmental responsibility.

C. Anticipated Growth

Projections indicate a steady increase in the demand for 316 stainless steel strips, with the China factory poised to play a pivotal role in meeting this demand. This anticipated growth is driven by emerging applications in green energy, automotive engineering, and advanced medical technologies.

VI. Conclusion

In conclusion, the 316 stainless steel strip, epitomized by the craftsmanship of the China 316 stainless steel strip factory, is an indispensable component in the global industrial landscape. Its resilience, coupled with its commitment to quality and sustainability, positions it as a material of choice across diverse applications. As we celebrate the one-year anniversary of this article, we also celebrate the enduring legacy of 316 stainless steel and the pivotal role played by the China factory in shaping its narrative.