Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

304 Stainless Steel in Chemical Engineering

Introduction

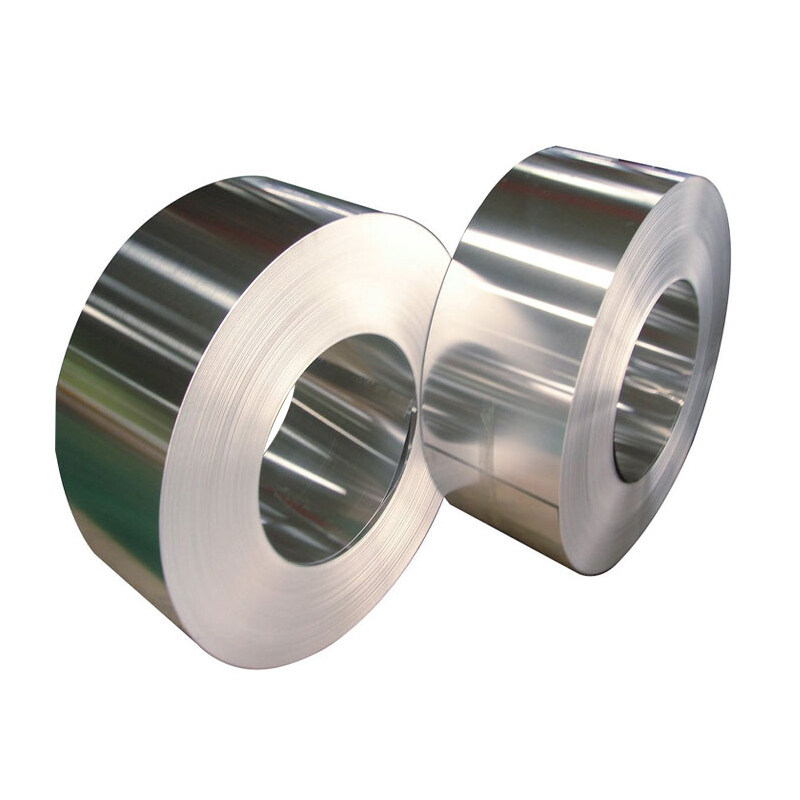

In the intricate tapestry of chemical engineering, the selection of materials is paramount to the operational success of equipment. Standing tall in this demanding arena is the esteemed 304 stainless steel, an alloy synonymous with durability and resistance to corrosion. This exploration into the multifaceted applications of 304 stainless steel within chemical equipment not only underscores its inherent attributes but also emphasizes the critical role of sourcing superior materials from a reliable "304 stainless steel sheet supplier."

Properties of 304 Stainless Steel

The allure of 304 stainless steel lies in its extraordinary corrosion resistance, a quality that anchors it as a cornerstone in chemical equipment fabrication. Beyond this, its commendable high-temperature performance and robust strength position it as the material of choice in environments where aggressive chemicals and extreme conditions prevail. As the landscape of chemical processes evolves, the demand for materials capable of withstanding these challenges elevates, elevating 304 stainless steel to an indispensable status.

Applications in Chemical Equipment

Storage Tanks and Vessels

The realm of storage tanks and vessels witnesses the indomitable presence of 304 stainless steel, where its resistance to corrosive agents translates into prolonged equipment lifespan and minimal downtime risks. As chemical storage needs diversify, the adaptability of 304 stainless steel becomes increasingly apparent, showcasing its versatility in accommodating a plethora of chemical compositions.

Piping Systems

Within the labyrinth of piping systems, 304 stainless steel emerges as the preferred conduit. Its resistance to corrosive fluids and meticulous adherence to industry standards make it a reliable transport medium for a spectrum of chemicals. This underscores the criticality of collaborating with reputable suppliers, whose role extends beyond mere provision to ensuring that the sheets align seamlessly with the nuanced demands of diverse piping systems.

Reaction Vessels

In the intricate dance of chemical reactions, 304 stainless steel takes centre stage, offering compatibility with a diverse array of chemical processes. Its influence on reaction kinetics is profound, impacting efficiency and contributing to the realization of desired outcomes. Here, the partnership with a trusted "304 stainless steel sheet supplier" becomes paramount, ensuring that the sheets used in construction seamlessly integrate with the nuanced requirements of varied chemical reactions.

Fabrication and Forming of 304 Stainless Steel

The journey from raw material to the final product involves a symphony of precision and expertise in the manufacturing of 304 stainless steel sheets. Sheet metal manufacturing, a pivotal aspect, demands a meticulous approach to produce sheets of impeccable quality in various thicknesses and sizes. The machining techniques applied further elevate workability, necessitating suppliers to adopt cutting-edge methods to meet the evolving needs of the dynamic chemical industry.

Case Studies: Successful Implementations

Delving into the annals of successful implementations of 304 stainless steel in chemical plants reveals invaluable insights into its real-world applications. Notable projects serve as beacons, illuminating the material's advantages, such as extended equipment life and unwavering resistance to corrosion. However, the journey is not devoid of challenges, highlighting the need for seamless collaboration between engineers, manufacturers, and suppliers to address the unique intricacies of each project.

Considerations for 304 Stainless Steel Sheet Suppliers

Choosing the right supplier emerges as a pivotal facet in ensuring the triumph of chemical projects employing 304 stainless steel. The stringent criteria encompass quality standards, industry certifications, and adherence to meticulous inspection and testing protocols. Reputable suppliers transcend conventional offerings, providing customization options that tailor sheets to the nuanced requirements of each project. This ensures a seamless integration of supplied materials into the complex fabric of chemical equipment.

Future Trends and Innovations

As we cast our gaze towards the horizon, the future of 304 stainless steel in chemical equipment is entwined with the continual evolution of alloy formulations. Ongoing research and development endeavours seek to refine the material, enhance its intrinsic properties, and expand its applicability. Simultaneously, emerging technologies in chemical equipment design and an escalating emphasis on sustainable practises will shape the landscape, influencing material selection criteria and supplier practises.

Conclusion

In the end, the indelible mark of 304 stainless steel in the chemical industry is a testament to its unparalleled resilience and adaptability. As we celebrate its myriad contributions over the years, it is imperative to recognise the pivotal role played by reputable suppliers, including the diligent "304 stainless steel sheet supplier," in providing the backbone for triumph in complex chemical projects. In an industry poised for continuous evolution, the harmonious interplay between innovation, reliability, and conscientious material resourcing will undoubtedly propel 304 stainless steel to new pinnacles within the dynamic tapestry of chemical engineering.