Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

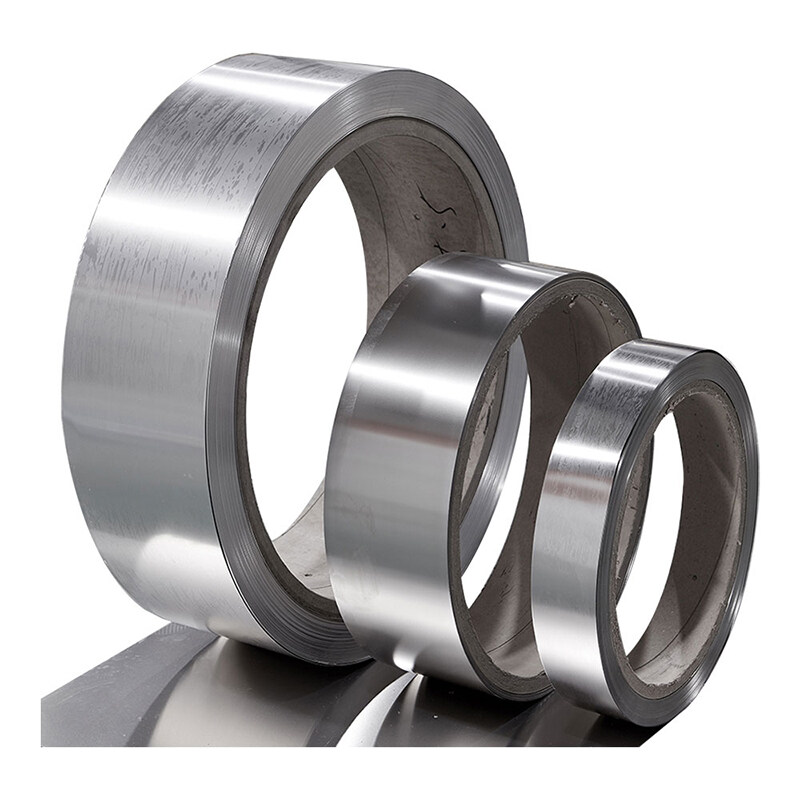

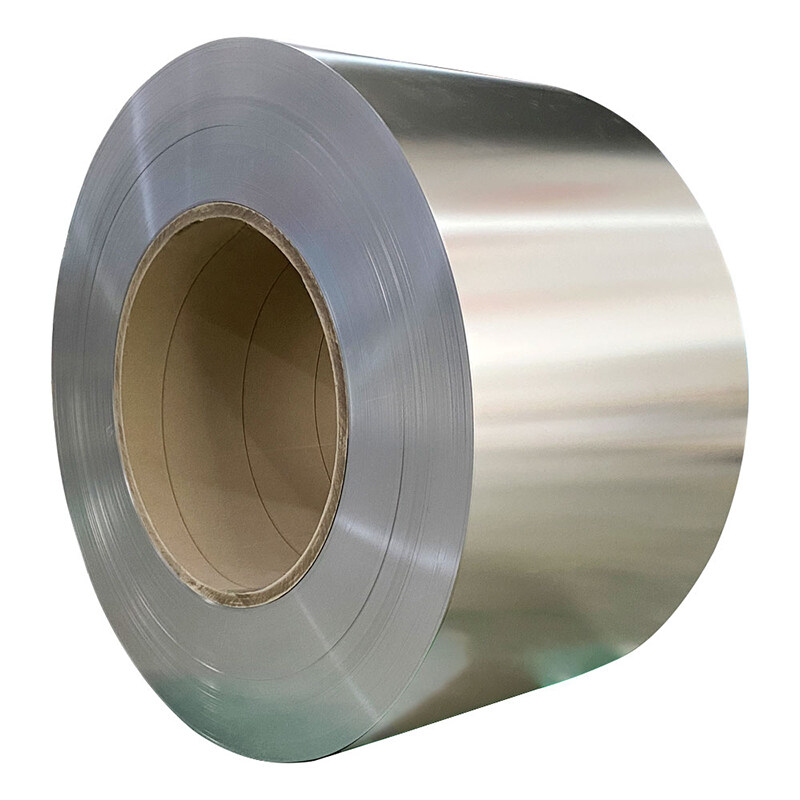

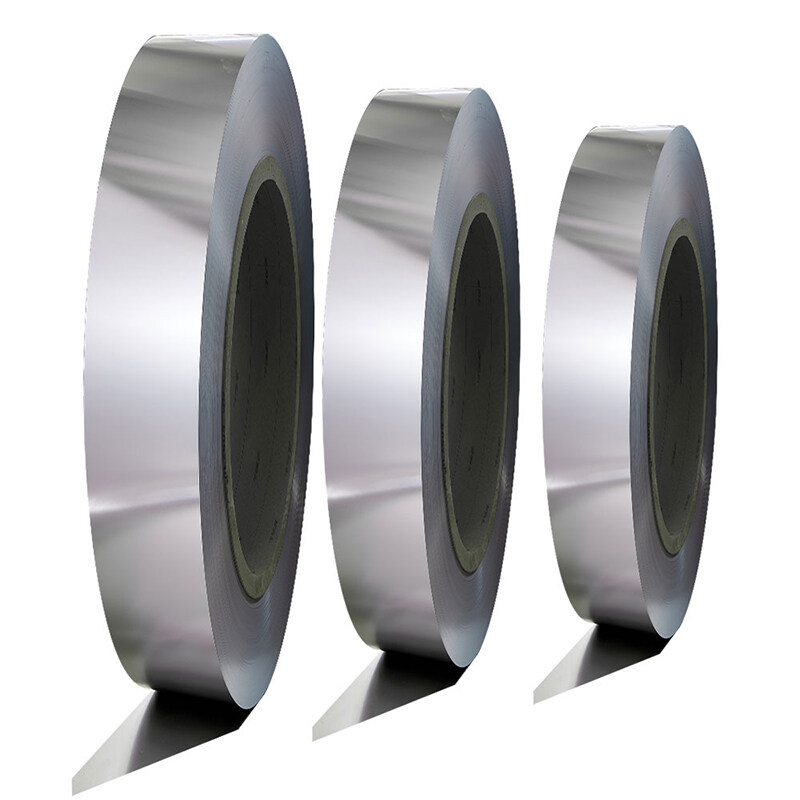

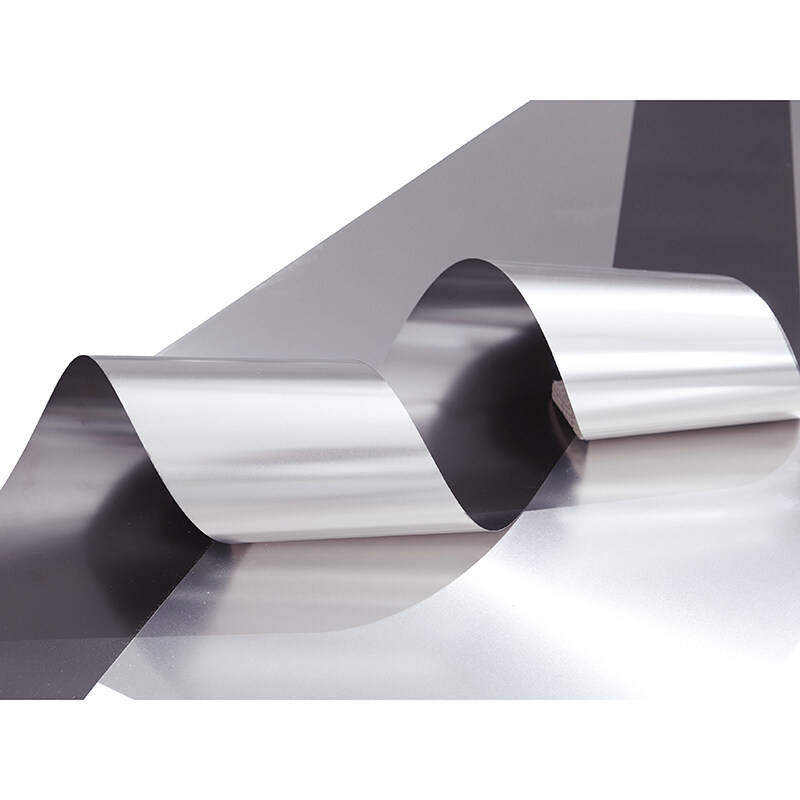

Painted Steel 304 316 stainless steel circle roll

Our painted steel circle rolls, PPGL coils, and PPGI coils made with 304 and 316 stainless steel are incredibly tough and durable, making them ideal for use in sea equipment that needs to withstand exposure to salty water. Our coils are designed to maintain their original condition, regardless of the liquids they come into contact with, making them suitable for a wide range of applications, including use in machines.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

The Painted Steel 304 316 Stainless Steel Circle Roll PPGL Coils are awesome because they can handle a lot! They’re super tough against corrosion and wear, and they can take the heat in high-temperature environments. Plus, they have a smooth surface that’s perfect for getting creative with your decor. Whether you want to keep it simple or go all out with your design, these coils have got you covered.

High Strength:

316 stainless steel contains a higher amount of carbon than 304 stainless steel, which makes it harder and more durable. This increased hardness gives it excellent resistance to wear and fatigue, making it ideal for use in high-temperature and high-pressure environments.

Special Coating Prevents Oxidization:

A special coating is applied to 316 stainless steel to prevent oxidization, ensuring that it maintains its corrosion resistance properties over time. This galvanized coating acts as a barrier, preventing oxygen and other reactive substances from coming into contact with the metal surface and causing it to corrode.

Low Carbon Content:

The 316 stainless steel reduces its susceptibility to carbide precipitation and intergranular corrosion. This means that it is less likely to experience degradation or failure due to these types of corrosion, making it a more reliable and durable material for use in a variety of applications.

Resistance to Chemicals:

The 316 stainless steel is highly resistant to a wide range of chemicals, including acids, alkalis, and chlorides, making it an ideal material for use in chemical processing and storage applications.

Suitable for Customization:

Painted Steel 304 316 Stainless Steel Circle Roll is a great material to work with because it’s easy to customize for specific applications. It has excellent welding and forming capabilities, which means it can be easily shaped and manipulated into different shapes and sizes. This makes it a popular choice for a wide range of applications, from industrial to decorative.

Product Parameter:

|

Material |

Stainless Steel |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Surface |

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

|

Standard |

JIS/BS/EN/ASTM/AiSi |

|

Surface Finish |

NO.1 |

|

Edge |

Mill Edge / Slit Edge |

|

Shape |

Flat/ Sheet/ Strip/ Coil |

|

Length |

Customized |

|

Thickness |

0.12-0.80mm or Customized |

|

Certification |

API, BIS, SABS, JIS, GS, ISO9001 |

|

Width |

1251-1500mm or As Request |

|

Tolerance |

±1% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Making Pipes, Cutting Sheets, Making Small Tools, Making Corrugated Sheets, Making Container, Making Fences |

What are the characteristics of stainless steel rolls?

1.The design of precision ball bearing, inner sleeve and outer sleeve is an important part of bearing components, which is not only beautiful, but also more importantly, the stainless steel roll is quieter.

2.The stainless steel roll end cover effectively prevents dust and splashes from entering the working environment.

3.The planning of stainless steel roll assembly allows it to work in special environment.

4.If necessary, sensitive grease or smooth grease can be used to configure smooth bearing mode.

5.Suitable for high-speed transportation. According to the diameter and length of the drum, the speed can change up to 120m / min.

6.Working temperature of stainless steel roll: -5 ~ + 40 ℃.

Do you know the application scope of stainless steel roll?

Stainless steel rolls are widely used, but most of them are used in some large machines. The drum is roughly cylindrical, which can be divided into active drum and passive drum. It is mainly used in printing machines, digital printers, conveying equipment and some packaging machinery.

Compared with different application fields, there are many kinds of stainless steel rolls, and the functions of stainless steel rolls and manufacturing materials are also different. Typically, drums made of natural rubber and triethylene propylene rubber.

Because the characteristics of material production also depend on the application field, because the winding drum has smooth surface and moderate friction, generally, the winding drum will be an important part of the belt conveyor system. In addition, the glue roller in the conveying system can improve the operation of the conveying system and ensure the mass operation of the stainless steel roll conveyor. In some logistics sorting, stainless steel rolls on the conveyor belt are very common.

This kind of conveyor can convey some solid substances, such as packaged flour, which is common in some large food factories. Of course, it can also transport some large equipment parts. The drum is simple and compact in structure and takes up less space. It is still very popular in some large factories.

The emergence of stainless steel rolls has helped people solve many transportation problems, so the use of drums can not only solve the friction caused by the wear of large transportation equipment on the machine, but also greatly improve the efficiency of machine transportation, which is also the reason why drums are welcomed by people.