Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

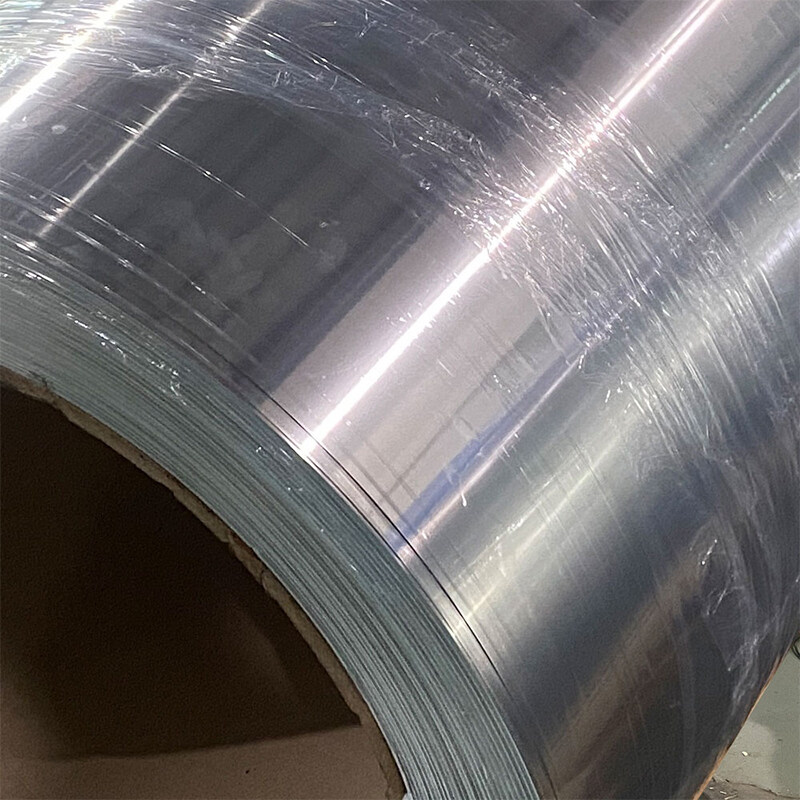

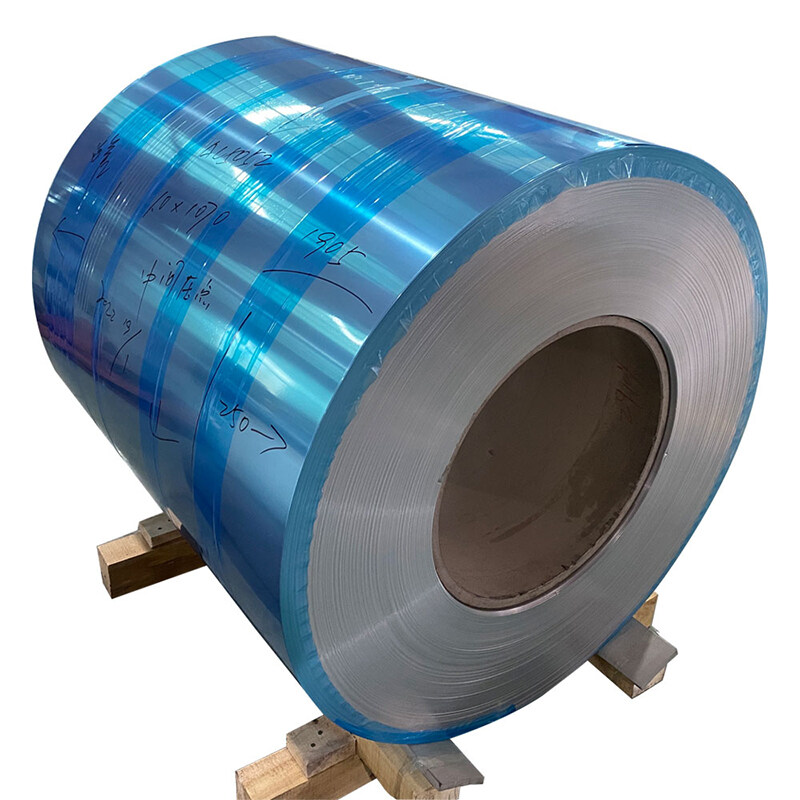

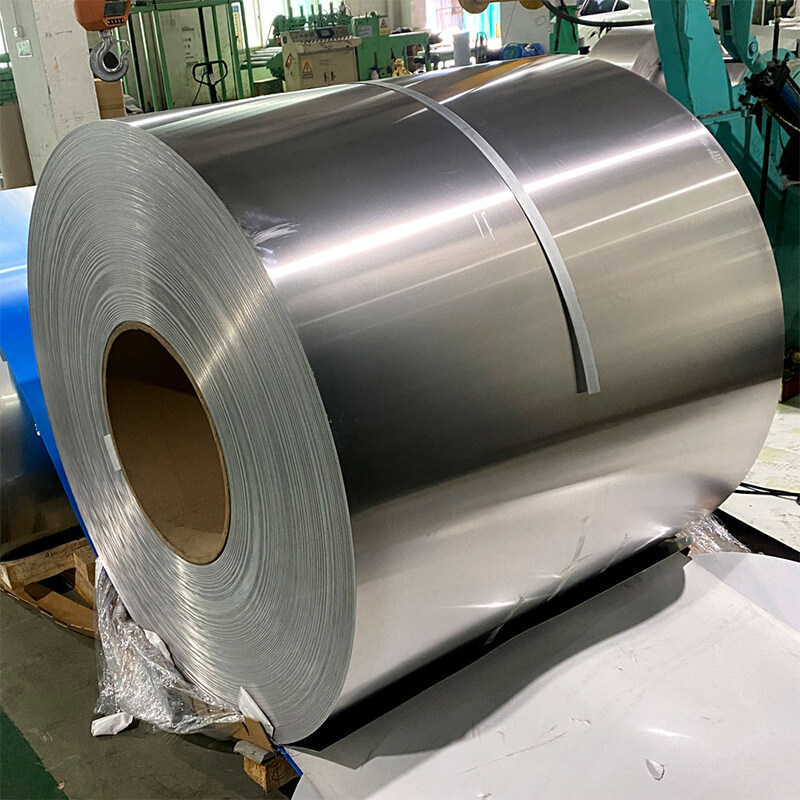

Plate sublimation 5052 3003 aluminium disc circle coil

Aluminum disc coil is perfect for plate sublimation. It is made from 5052 and 3003 grade aluminum, making it highly durable and long-lasting. The disc coil is designed to be corrosion-resistant and has excellent thermal conductivity. It is also lightweight and easy to install, making it ideal for a variety of applications.

The Plate Sublimation 5052 3003 Aluminum Disc Circle Coil is super tough and can last a lifetime. This coil is built to resist corrosion and has amazing heat conductivity. Plus, it’s lightweight and a breeze to install, making it perfect for all sorts of uses. It’s a great choice for small businesses too!

Highly Resistant to Stress and Cracking:

The 5052 3003 aluminum disc circle coil’s exceptional stress and crack resistance make it a reliable material for use in high-stress and high-temperature applications. This means that it can withstand extreme conditions without breaking or cracking, making it a popular choice for industries such as aerospace and automotive. Its ability to maintain its structural integrity under pressure and high temperatures makes it a dependable material for critical applications.

Highly Reflective:

The 5052 3003 aluminum disc circle coil’s ability to reflect light effectively and distribute it evenly makes it a top choice for lighting fixtures and reflectors. This feature is especially useful in commercial and industrial settings where bright and uniform lighting is essential. Additionally, the coil’s high reflectivity is perfect for decorative applications, such as in architectural features and signage. It’s a versatile material that can be used in a variety of applications, thanks to its reflective properties.

Application for 5052 and 3003 Aluminum Circle Coil:

The 3003 aluminum plate is perfect for use in damp environments, like packaging, refrigeration, air conditioning, and ventilation systems. Meanwhile, the 5052 aluminum plate is a go-to for electrical enclosures, transportation vehicles, and pressure vessels. It’s also a popular choice for making fuel tanks and tubing for cars and airplanes.

Product Parameter:

|

Material |

aluminum |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Standard |

ASTM/ AISI/ JIS/ DIN/ GB |

|

Temper |

O - H112 |

|

Surface |

Mill |

|

Grade |

1000,2000,3000,4000,5000,6000,7000 Series |

|

Length |

Customized |

|

Thickness |

Customized |

|

Surface Treatment |

Coated |

|

Width |

250-1500mm or Customized |

|

Tolerance |

±3% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Construction and Decoration |

We’re a professional manufacturer of stainless steel circle coils. If you’re looking for custom options, feel free to reach out to us! We offer a range of materials, including 201, 304, 304L, 316, 316L, and 430 stainless steel, as well as different surface treatments like BA, 2B, NO.1, NO.3, NO.4, 8K, HL, 2D, and 1D. We also have various grades available, such as the 1000, 2000, 3000, 4000, 5000, 6000, and 7000 series. So, if you have any ideas or specific needs, don’t hesitate to contact us!

What alloy are 3003 aluminum and 5052?

3003 mainly forms an alloy with manganese (MN), while the main alloy component of 5052 is magnesium (mg). In short, you will see that 3003 is an alloy of silicon, iron, copper, magnesium and zinc, while 5052 is an alloy of silicon, copper, manganese, magnesium, chromium and zinc. The percentages of alloying elements in various commonly used alloys are shown in the table below.

ALUMINUM SPEC SHEET

Nominal chemical composition

Alloying elements - Percentage

AlloySiFeCuMnMgCrZnTi

30030.6 0.7 0.2 1.0/1.5 0.0 0.0 0.1 0.0

5052 . 45 0.0 0.1 0.1 2.2 0.15 0.1 0.0

What is the difference between 3003 and 5052 aluminum? 3003 vs 5052

5052 aluminum plate and 3003 aluminum plate are the most common alloy aluminum plate on the market at present. Now let's take 3003 H24 aluminum plate and 5052h32 aluminum plate as examples to popularize this knowledge.

- Chemical composition: 3003 aluminum plate is an aluminum manganese alloy, and the main alloy element is manganese. 5052 aluminum plate is an aluminum magnesium alloy, and the main alloy element is magnesium. The aluminum content of 3003 aluminum plate is slightly higher than that of 5052 aluminum plate.

- Mechanical properties. 3003h24 aluminum plate is an aluminum manganese alloy, and the main alloy element is manganese. The tensile strength of 3003h24 aluminum plate is 145-195rm/mpa, while that of 5052 H34 aluminum plate is 230-280rm/mpa, which is much higher than that of 3003h24aluminum plate; The tensile strength of 3003h24 aluminum plate is 115rm/mpa, while that of 5052 H34 aluminum plate is 150rm / MPa. Therefore, the performance of 5052 aluminum plate is significantly better than that of 3003 aluminum plate.

It can be seen from the mechanical properties of 3003 & 5052 that the slight change of alloy composition has a great influence on the tensile strength. 3003 h14 has an ultimate tensile strength range of 20 – 26 Ksi, a yield value of 21, an elongation of 8.3%, and a Brinell hardness of 40, while 5052 H32 has an ultimate tensile strength range of 31 – 38 Ksi, a yield value of 28, an elongation of 12%, and a Brinell hardness of 60. Please refer to the table below to understand the difference in mechanical properties between the two alloys.

3 . Specifications. 3003 h14 aluminum plate is mainly thin plate, and thick plate is not widely used; The 5052 aluminum plate is widely used except for thin and thick plates.

- Use. 3003 aluminum plate is mainly used in humid environments, such as product packaging, refrigerators, air conditioners, cold storages, ventilation ducts, etc. 5052 aluminum plate is commonly used in electrical enclosures, transportation vehicles, pressure vessels, etc. It is a commonly used material for manufacturing fuel tanks and tubing for automobiles and aircraft.

- Price of aluminum plate. The price of 3003 aluminum plate is slightly higher than that of pure aluminum plate, while the price of 5052 aluminum plate is significantly higher than that of 3003 aluminum plate. According to the specifications and thickness, the price of 5052 aluminum sheets per ton is higher than that of 3003 aluminum sheets per ton. But the higher density of 3003 may offset the lower price. To calculate the weight of the aluminum plate, the following formula can be used:

Decimal thickness * width * length * density = weight of aluminum plate.

3003 aluminum has a density of 0.099 lb / inch3, while 5052 has a density of 0.097 lb / inch3. For example, to calculate the weight of 3003 aluminum plates with a thickness of 0.125 inches and non-standard sizes of 48 inches and 82 inches, you need to multiply 0.125 * 48 * 82 * 099 to get a value of 48.71 pounds. You can already see how the higher density of 0.099 can offset the higher cost of 5052 aluminum alloy. In this case, 5052 sheets will be 47.72 pounds. The greater the purchase, the greater the impact of density differences. 5052 and 3003 can also be purchased in rolls, but in this case, they are usually sold by weight.