Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

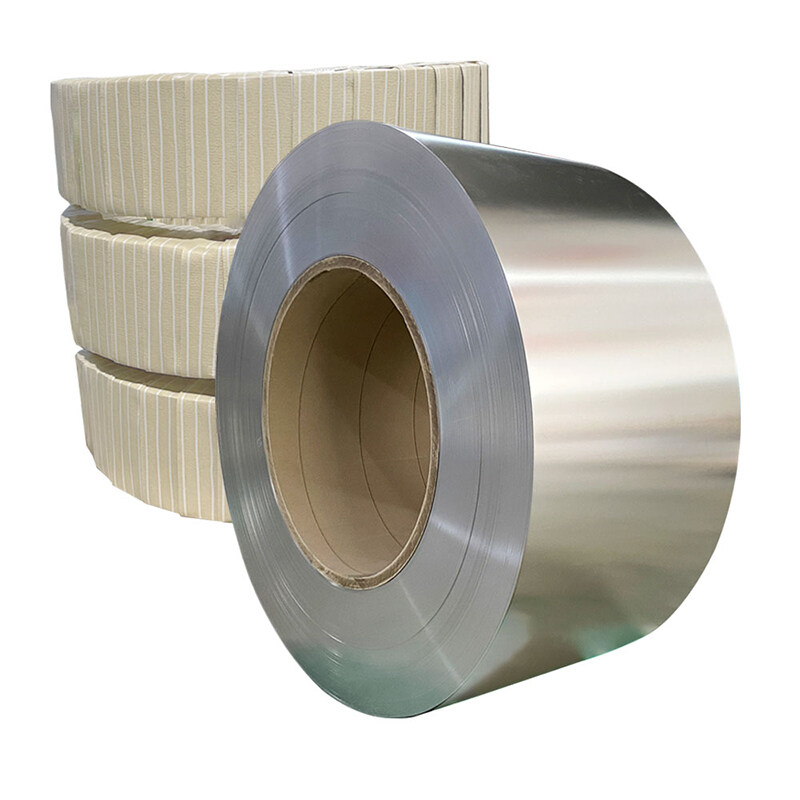

OEM 316 stainless steel cold rolled

In the realm of stainless steel, the 316 grade stands as a pinnacle of corrosion resistance and durability. When subjected to the meticulous process of cold rolling, 316 stainless steel transcends expectations, emerging as a material of choice for critical applications in various industries.

Understanding the Superiority of 316 Stainless Steel: A Primer

316 stainless steel is renowned for its exceptional corrosion resistance, making it indispensable in harsh environments such as marine settings and chemical processing facilities. The cold rolling process further elevates its properties, offering a spectrum of advantages that redefine its applications.

Cold Rolling Brilliance: Enhancing 316 Stainless Steel

-

Optimized Strength and Hardness: Cold rolling involves passing stainless steel through rollers at ambient temperature. This process not only refines the material's surface finish but also optimizes its strength and hardness, making 316 stainless steel suitable for demanding structural applications.

-

Precision Thickness Control: Cold rolling provides precise control over the thickness of the stainless steel. This precision is crucial in industries such as aerospace and medical, where components must adhere to strict dimensional specifications.

-

Surface Finish Excellence: The cold rolling process imparts a superior surface finish to 316 stainless steel. This is particularly valuable in applications where aesthetics matter, such as architectural elements, kitchen equipment, and consumer appliances.

Applications Across Industries: Where Cold-Rolled 316 Stainless Steel Shines

-

Medical and Pharmaceutical: The precision and cleanliness achieved through cold rolling make 316 stainless steel an ideal choice for medical equipment and pharmaceutical applications where hygiene and dimensional accuracy are paramount.

-

Aerospace Engineering: In the aerospace industry, where lightweight strength and corrosion resistance are critical, cold-rolled 316 stainless steel finds applications in components ranging from structural elements to fasteners.

-

Food and Beverage Processing: Cold-rolled 316 stainless steel's corrosion resistance and smooth surface finish make it a preferred material for equipment in food and beverage processing, ensuring hygiene and compliance with stringent industry standards.

-

Architectural Marvels: The aesthetic appeal and durability of cold-rolled 316 stainless steel contribute to its use in architectural designs, where it adorns structures with a sleek, modern, and corrosion-resistant finish.

The Future of Cold-Rolled 316 Stainless Steel: Precision Redefined

As industries evolve, the demand for materials that offer a perfect blend of strength, durability, and aesthetics continues to grow. Cold-rolled 316 stainless steel stands at the forefront of this evolution, redefining the benchmarks for precision in material engineering.

Conclusion: Elevating Excellence in Stainless Steel

In conclusion, the marriage of 316 stainless steel and cold rolling processes results in a material that transcends conventional expectations. From enhancing strength and precision to delivering a flawless surface finish, cold-rolled 316 stainless steel paves the way for innovation across industries, setting new standards for excellence in the world of stainless steel.

430 gold nickel plated duplex gold stainless steel coil foil

430 gold nickel plated duplex gold stainless steel coil foil is the perfect choice for all your needs. Its high-quality stainless steel construction ensures long-lasting durability and superior corrosion resistance. The coil foil is plated with a luxurious gold nickel finish that adds a touch of elegance to any project. The gold plating also helps to protect against tarnishing and discoloration. This stainless steel coil foil is perfect for a variety of applications, including automotive, construction, and industrial projects. With its superior strength and corrosion resistance, it's sure to provide years of reliable performance.